Overview

Challenges

- Ultra-deepwater well—seafloor at 9,715 ft (2,961 m)

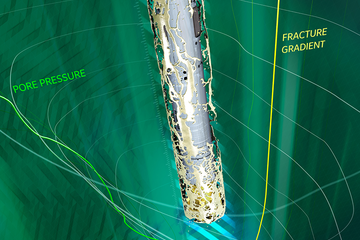

- Narrow drilling window

- Deviated borehole with maximum inclination of 45°

- Projected downhole mud losses of 6,000 bbl

Results

- Improved ROP to reach total depth 8 days earlier than planned

- Extended the drilling window and reduced the delta between ECD and ESD to less than 0.5 ppg

- Reduced downhole mud losses by 86%

- Captured $5.5 million USD in rig time reduction savings

An operator in the Gulf of Mexico struggled with an ultra-deepwater exploration well. The directional well—one of the deepest in Mexico with a water depth of 9,715 ft (2,961 m)—had a projected inclination of 45°. It was expected to lose approximately 6,000 bbl of drilling fluid in intermediate hole sections based on offset well data. In addition, the narrow drilling window made reaching target depth a challenge.

The operator was drilling in formations that required mud density ranging from 9.2 ppg (1.10 sg) to 11.3 ppg

(1.35 sg). The drilling fluid needed to withstand 12,000 psi and 187°F (86°C), while maintaining constant rheology, lower viscosity, and fragile gel strengths in order to optimize drilling performance. Complex shales and sandstones were expected, along with lost circulation.

To achieve these drilling objectives, Baker Hughes recommended the operator use the DELTA-TEQTM low-pressure-impact drilling fluid. The DELTA-TEQ fluid is a non-aqueous, advanced formulation of specialized clay and polymers that creates a non-progressive gel structure, and reduces hydraulic impact with a rapid-set/easy-break profile. This profile maintains fluid integrity if operations are paused, mitigates pressure spikes when circulation resumes, and protects the formation from surge pressures when running casing.

Download the PDF to read the full case study.