Highlights

Highlights

Benefits

- Collect casing and cement integrity measurements any time you run drill pipe in the well

- Reduce cost and rig time required to obtain well integrity data

- Eliminate the need for a dedicated logging run

Applications

- Slot recovery

- Whipstock casing exits

- Cut and pull operations

Overview

Casing, cement, and barrier integrity is critical across the well lifecycle to maintain safety, improve efficiency, and increase well productivity.

Whether driven by local regulations or operational best practices, there is a growing need for cased-hole well integrity evaluation. However, in some operations—especially during completion, intervention, and abandonment—you’re limited in how you can gather integrity data, leading to excess rig time and costs. In today’s environment with rig time savings being more critical than ever, that economic challenge is amplified when it comes to offshore, high-dollar assets.

Get the data real time, any time

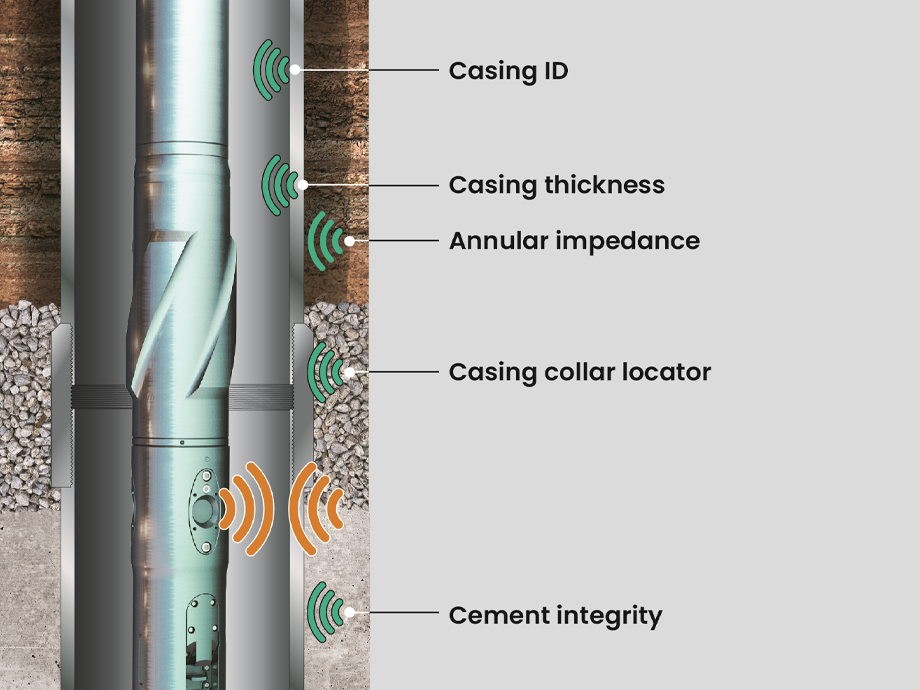

Baker Hughes offers the industry’s only cased-hole, pipe-conveyed ultrasonic casing and cement evaluation service. This means, you no longer have to make dedicated logging runs to obtain the needed measurements to confirm well integrity. With xSight™ casing integrity and cement mapping (CICM) services, you can get this data any time you run pipe in the well.

Leveraging our xSight CICM services, you can avoid the excess time it takes to rig up and run a logging tool, substantially reducing the cost required to get the data you need. This also eliminates additional personnel to perform the job, cutting spend associated with lodging, day rates, travel, etc. And, you get the added benefit of obtaining multiple integrity measurements with one tool, in a single run.

By gathering the data during the actual operation, rather than a separate trip, you can make real-time, actionable decisions as the job is happening.

Contact your local Baker Hughes representative to learn how our xSight casing integrity and cement mapping services can deliver a cost-effective solution for your well integrity needs by obtaining the needed measurements any time you run pipe in the well.

Evaluate reusability of casing above kickoff point

Accurately locate casing collars and stabilizers to avoid milling through them

Identify presence of cement to improve milling performance

Verify well barriers in real time

Orient the whipstock

Obtain casing annular measurements to confirm what is behind the casing and optimize cut location

Avoid multiple cut and pull attempts

Verify well barriers in real time

Evaluate free pipe

Confirm cement integrity

Confirm cement integrity during liner cementing

Provide hook hanger imaging for multilaterals

Verify casing cleaning before running in completion equipment

Optimize downhole isolation placement

Identify casing eccentricity to orient perforation and cutting to avoid outer casing damage