Highlights

Highlights

Benefits

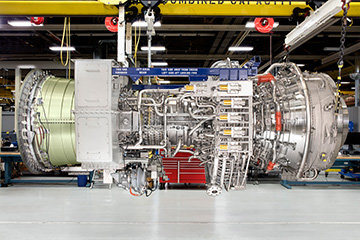

- Optimization options: max power version at 38.3 MW and 41% efficiency, or other version for low emission and extended maintenance

- Maximized maintenance flexibility reaching up to 36,000-hour inspection interval and 72,000-hour overhaul

- Best-in-class NOx emissions as low as 15-25 ppm

Features

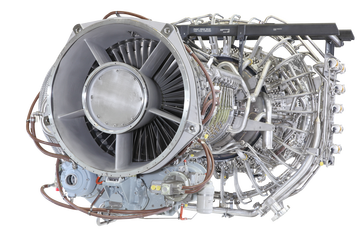

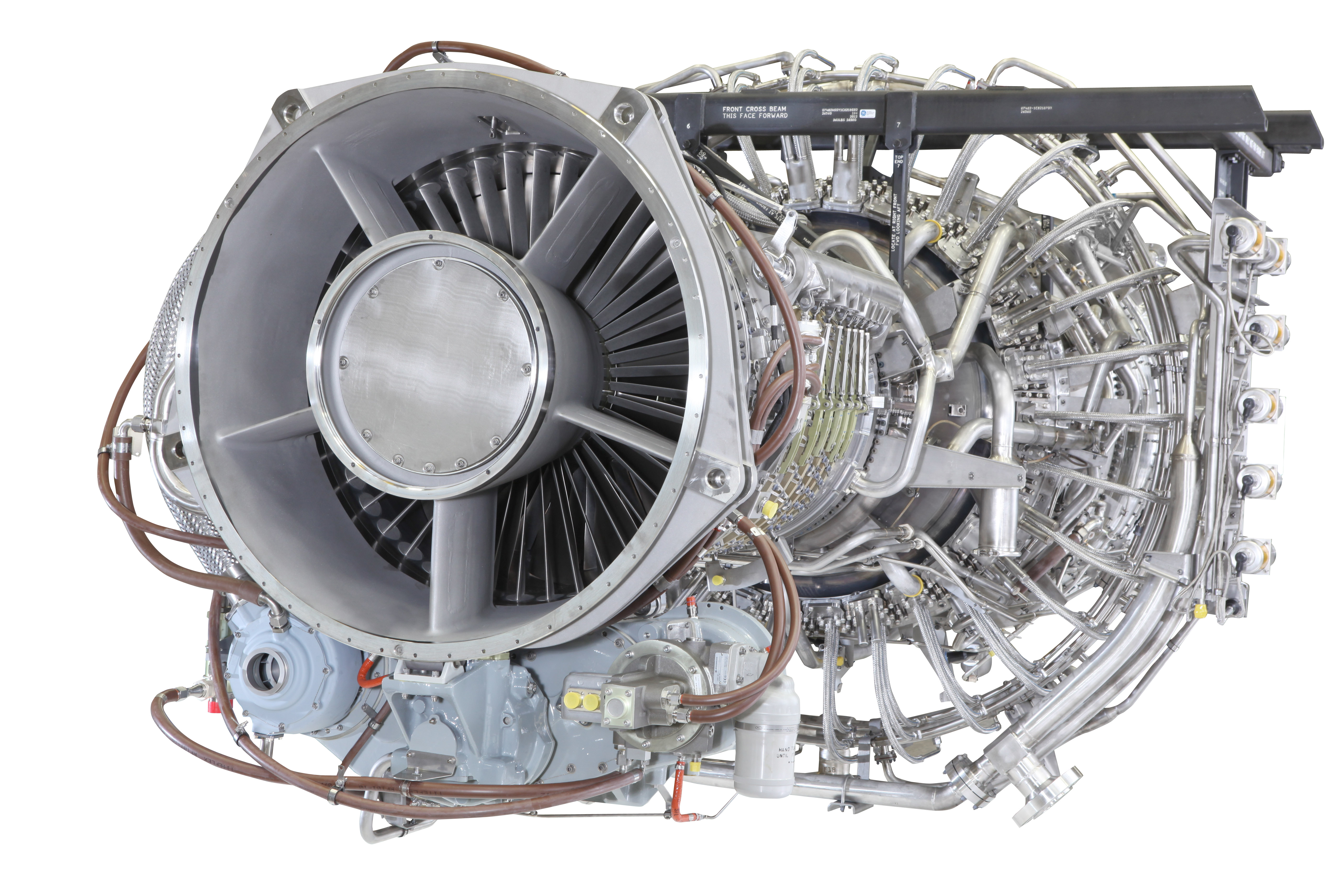

- High-pressure compressor inherited from G4 with redesign for enhanced durability

- Combustor leverages latest DLE technologies and capabilities from the LM6000

- Gas generator leverages GE Aviation technologies; high-speed power turbine includes aerodynamic and thermal modifications

Applications

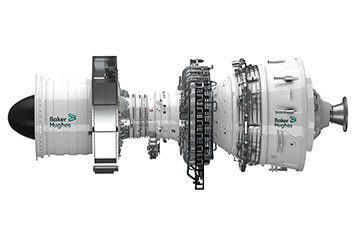

- Onshore and offshore

- LNG, pipeline, gas processing

- Power generation

Featured Video

Featured Video

Overview

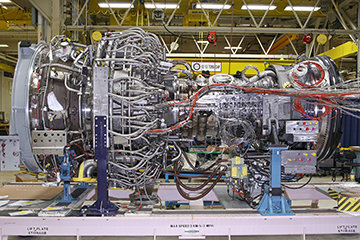

G5 is the latest technology generation of our PGT25/LM2500 aeroderivative gas turbines family that includes over 2,500 engines with nearly 100 million combined operating hours in applications around the world.

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Package dimensions exclude driven equipment.

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Package dimensions include driven equipment.

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Package dimensions include driven equipment.

Best-in-class efficiency and lowest CO2

Thanks to our latest technology injections for increased firing temperature and optimized cooling flows, the G5 delivers the highest efficiency and power in the 20 to 40 MW power class.

Flexibility for power, maintenance, and emissions

The turbine can be tailored to customer needs—with 25,000/50,000 inspection intervals and 25 ppm NOx in high-power mode, or 36,000/72,000 and 15 ppm NOx when operating in Xtend 15 ppm mode.

Product Resources