Highlights

Highlights

Benefits

- Highest thermal exhaust energy with highest efficiency (85%) in combined heat power cycle

- Highest exhaust temperature for high-quality steam

- Higher availability thanks to lower operating maintenance costs—engine swap in 24 hours

Features

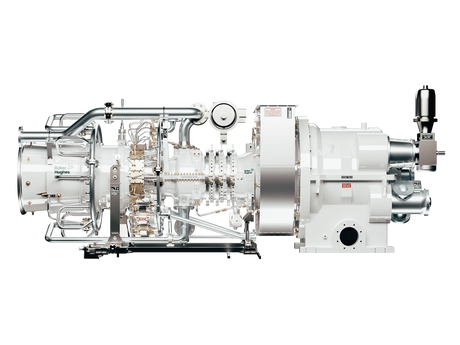

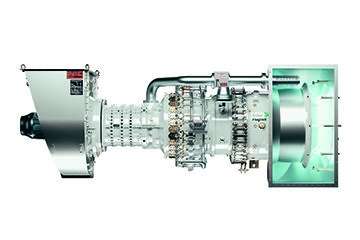

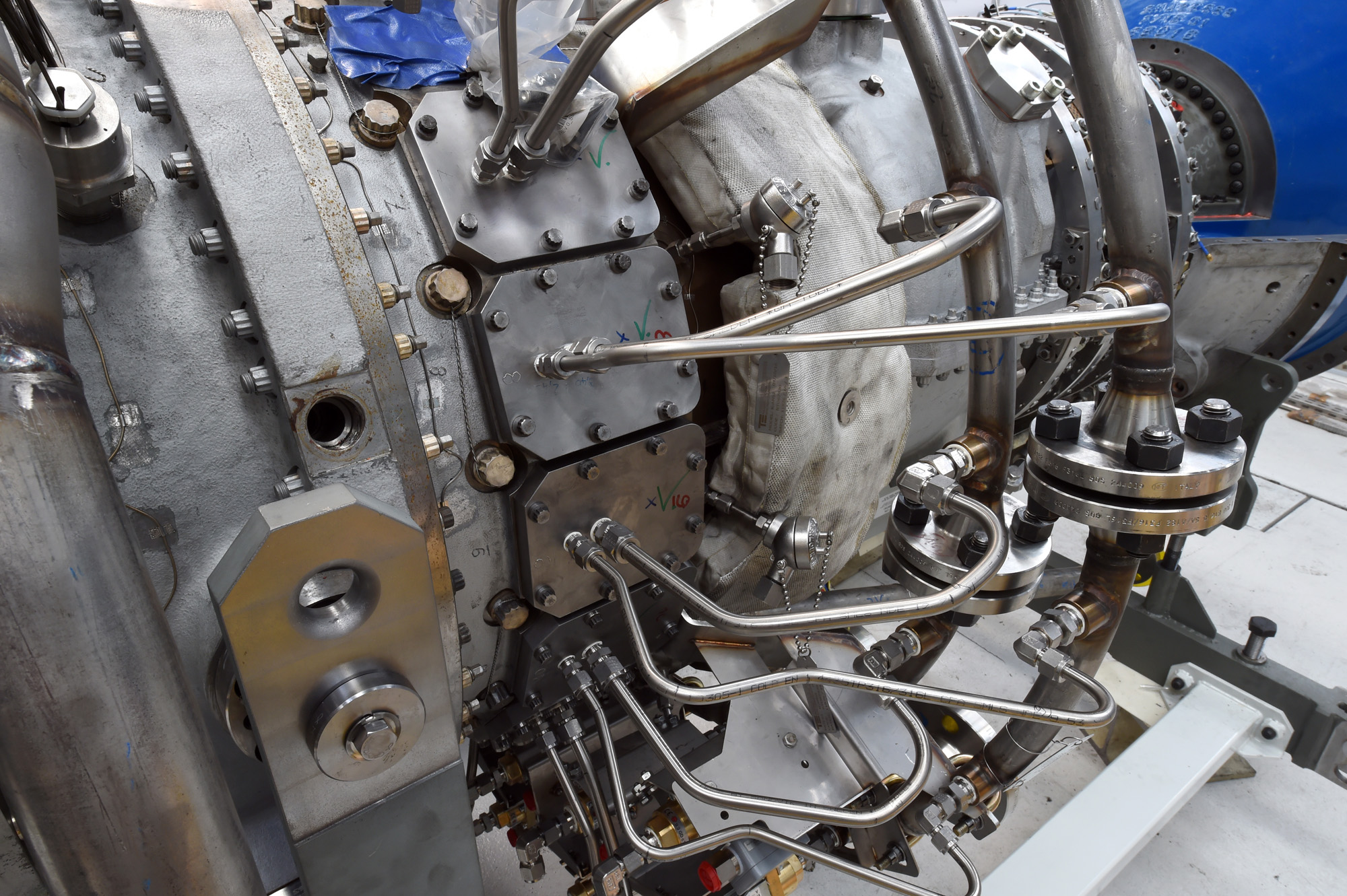

- Rugged 11-stage axial flow compressor with one inlet guide vane (IGV) and two variable IGV stages

- Low emissions and wide fuel flexibility with single-row annular combustion system

- High efficiency two-stage reaction turbine with air-cooled first stage

Applications

- Industrial

- Combined heat and power

- Oil and gas

Featured Video

Overview

Overview

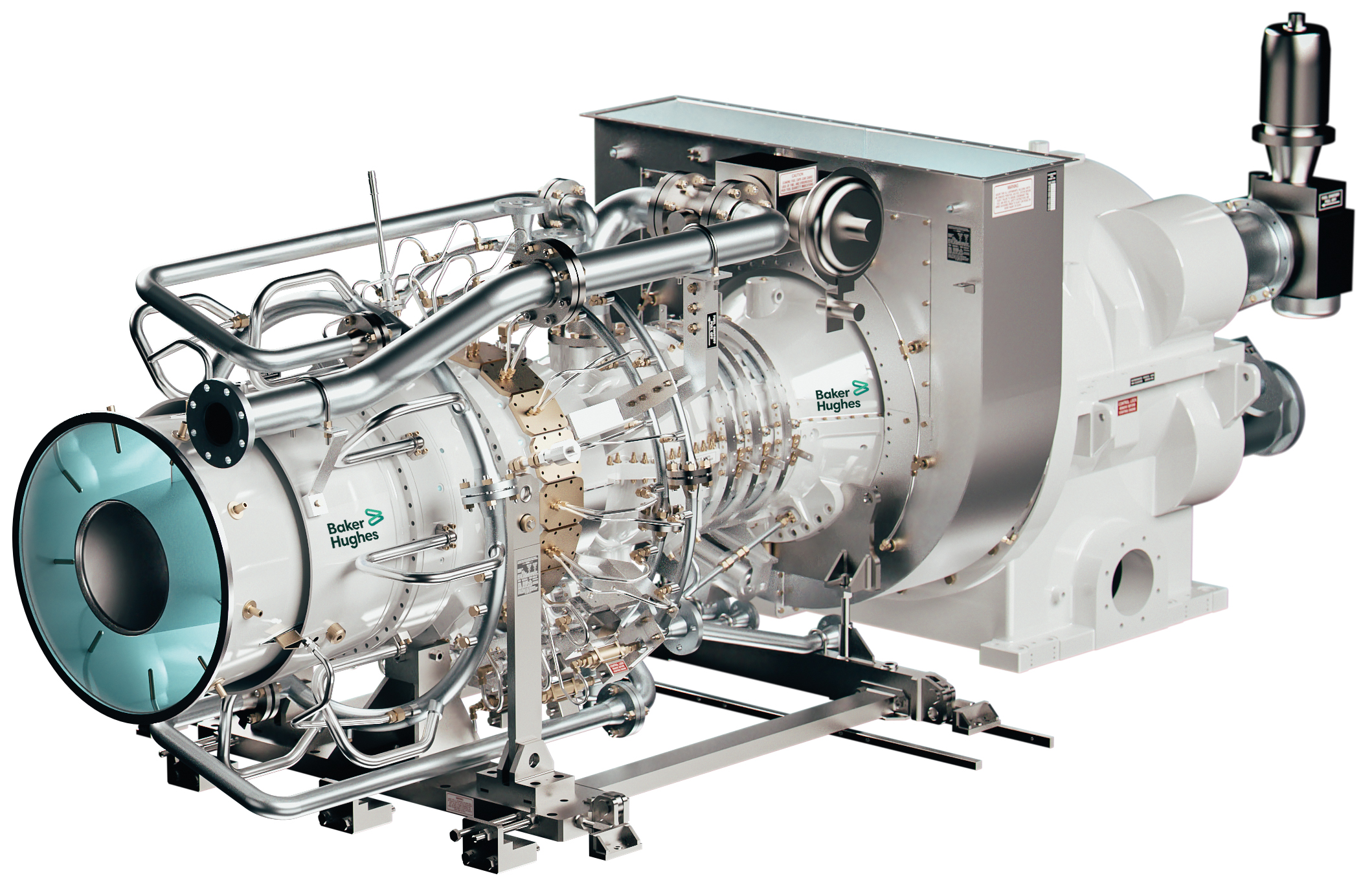

Building on innovations from our NovaLT™ 12 and 16 gas turbines, the NovaLT™5-1 gas turbine is based on technology which has been well-proven in applications around the world—with over 450,000 operating hours with approximately 80,000 running hours.

Specification

Power generation (50/60 Hz)

Power (MWe)

5.5

Efficiency @ generator terminals (%)

29.4

NOx emissions (ppm)

15

Exhaust temperature (ºC/ºF)

580/1,076

Speed (rpm)

16,630

Hot gas path inspection (hours)

24,000

Major inspection (hours)

48,000

Package dimensions (m/ft)

6.1x2.4x3/20x7.9x9.8 (LxWxH)

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Package dimensions include driven equipment.

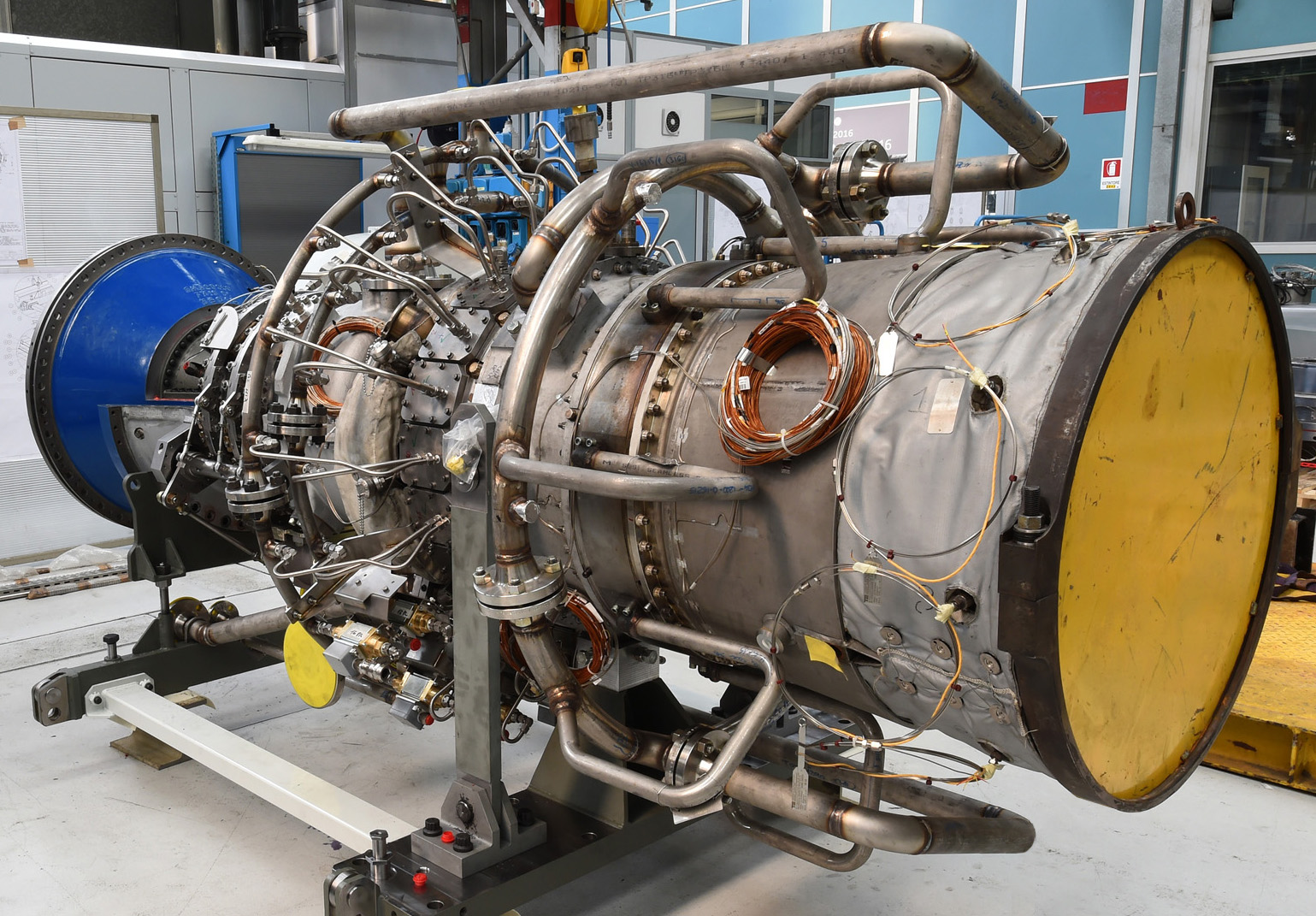

Availability and reliability enhancement

The NovaLT™5-1 gas turbine has optimized instrumentation to maximize unit availability and reliability.

Fast installation

It’s designed for installation in just 41 working days: the single-lift package and filtering and ventilation system are pre-assembled and tested at our site before shipping.

Maintenance

It delivers low maintenance costs, high availability, and 24-hour engine swap thanks to plug-and-play electrical connectors. Real-time condition monitoring anticipates and helps prevent problems. If problems do occur, 24/7 product support service is available.

Efficiency and flexibility

The NovaLT™5-1 gas turbine provides up to 30% electrical efficiency, up to 85% in combined heat and power (CHP), and it delivers high performance over a wide range of operations.

Hydrogen for energy transition

NovaLT™5-1 gas turbines can burn up to 30% hydrogen in dry low emission mode, and we’re moving toward 100% H2 capability.