Highlights

Benefits

- Permits tailoring to specific casing sizes with flexible design and hole-pattern flexibility

- Optimizes OD/ID dimensions to allow for larger production rates

- Offers a reliable sand control solution in highly erosive environments where conventional wire wrap and premium screens fail easily

Applications

- Primary and remedial sand control

- Highly corrosive and erosive environments

- HP/HT wells up to 7,500 psi and 500˚F (260 ˚C)

The BEADSCREEN™ high-performance erosion-resistant sand control system allows sand control media to be integrated into the remedial completion for a stronger, more versatile, economical remedial solution.

The screen contains inserts installed within the wall of the base pipe, which offer greater tensile, compression, bending and burst ratings compared to competitor ceramic or erosion resistant screens. The highly efficient, versatile system reduces installation complexity and equipment on site and can be installed much faster than competitor systems for an increased return-on-investment.

STRONGER

The BEADSCREEN system is a robust, erosion- and corrosion-resistant technology that is adjustable to the sand control needs of today’s remedial well completions.

The BEADSCREEN high-performance erosion-resistant sand control system offers greater mechanical strength than any other screen alternatives. This robust system has greater tensile, compression, bending and burst ratings compared to competitor ceramic or erosion resistant screens – which means you can install it faster, deeper, and safer.

The BEADSCREEN system can also be a reliable sand control solution in highly erosive environments where conventional wire wrap and premium screens fail easily. It’s highly erosion-resistant design allows for higher production rates compared to competitive systems for increased ultimate recovery.

And, in HPHT environments where conventional screens are not suitable, BEADSCREEN offers a superior alternative, and can withstand temperatures up to 600˚F.

MORE VERSATILE

The BEADSCREEN system offers unparalleled reliability and flexibility, especially during workover and remedial operations, and is available in any conventional API-sized pipe, with mesh size ratings from 50 microns up to 1,350 microns.

Unlike competitive systems, the BEADSCREEN system offers the most versatile sand control designs on the market. This means you can:

- Use it in a higher variety of applications, such as remedial sand control and high-rate gas wells

- Customize your flow area and increase productivity through optimized flow paths

- Customize the number of BEADSCREEN inserts per foot of pipe to achieve maximum inflow

- Run remedial screen even on installations with limited space and/or conveyance/riser limitations

MORE ECONOMICAL

The system reduces installation complexity and equipment on site, is highly efficient, and can be installed much faster than competitor systems for quicker return-on-investment. These impact-resistant screens can also be installed using slickline vessels, further reducing the cost of deployment, and are fully customizable to retrofit any remedial application.

HOW IT WORKS

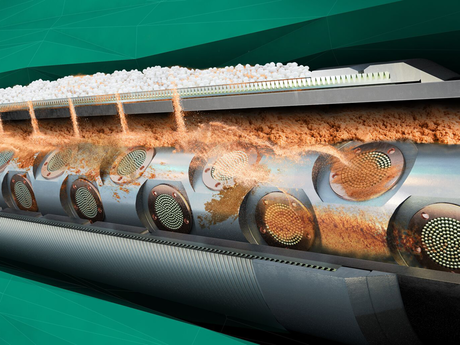

The BEADSCREEN incorporates mono-sized stainless steel or Inconel spheres, tightly bonded using a proprietary process to produce porous structures in an insert.

Bonded BeadScreen inserts eliminate sand ingress into the production tubing by allowing formation particles to bridge and pack against the bead matrix. Despite this sand bridging, production fluids freely flow though the high permeability media in the insert and enter into the screen base pipe. Numerous screen inserts are installed into a blast joint chassis which is then made up to the remedial or completion string, similar to conventional tubulars, and is deployed into the well. The bonded screen insert density (number of inserts per foot of pipe) is optimized to allow for maximum inflow area to the screen.

The BEADSCREEN inserts come in two standard sizes allowing for a fit-for-purpose design in a wide range of screen (outer diameter) sizes. The system material filtration matrix is then tailored to the customer’s formation Particle Size Distribution (PSD) to allow for sustainable sand control.

BEADSCREEN also offers self-cleaning characteristics through rhombohedral packing, to create pores of increasing sizes. Controlling the packing within the BeadScreen leads to a self-cleaning porous media, which in turn leads to lower mechanical skin.

BEADSCREEN can be integrated with a variety of Baker Hughes deployment solutions and can be installed in a well via any conduit and even in live well conditions if required.