Highlights

Highlights

Benefits

- Excellent availability and reliability: compact mover, designed for long life and ease of maintenance

- Enhanced fuel flexibility with no impact on combustor operability or integrity

Features

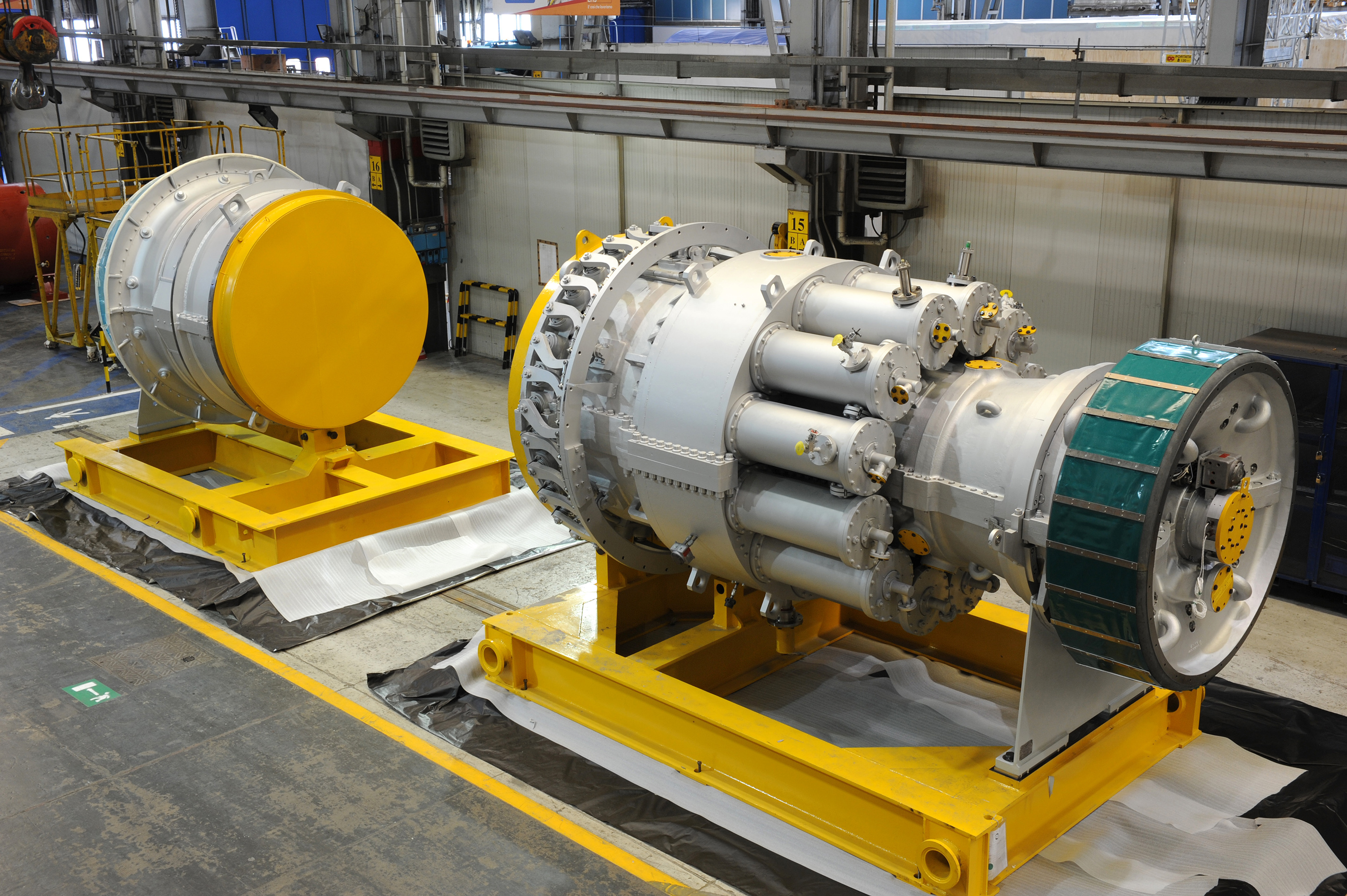

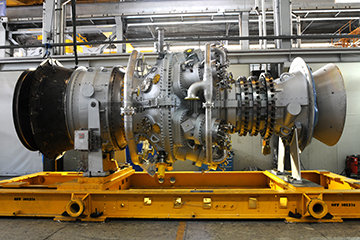

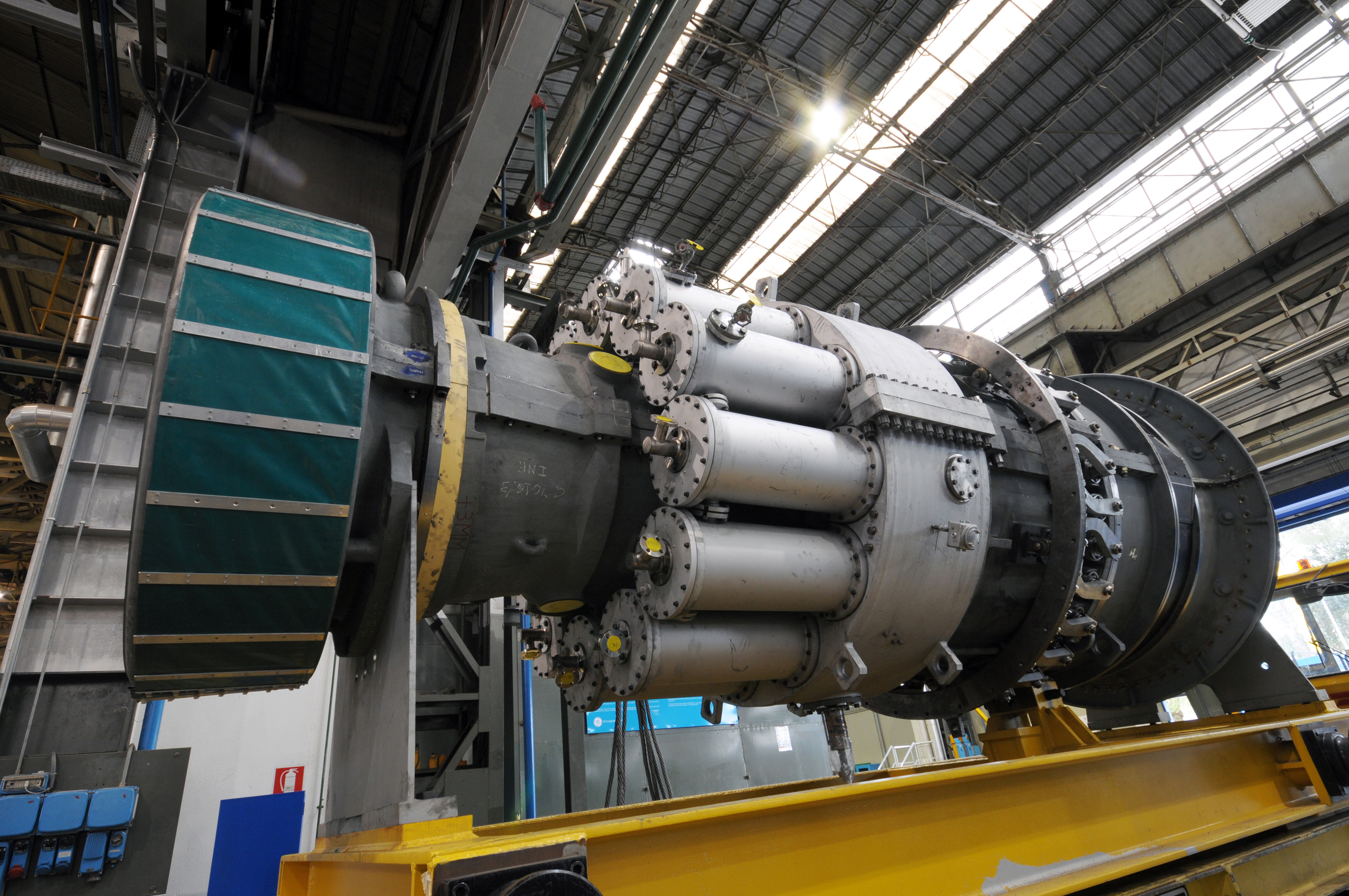

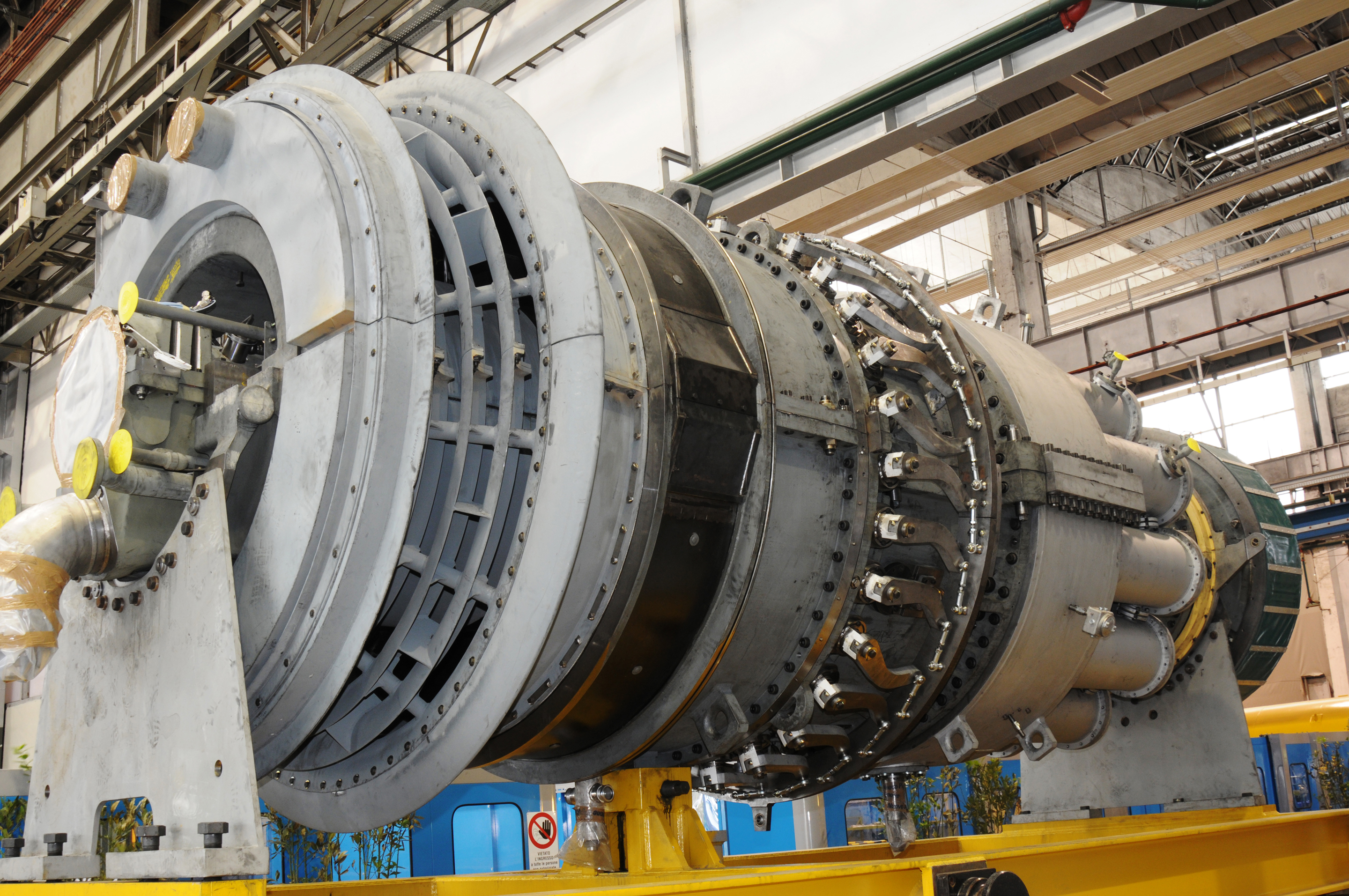

- 17-stage axial compressor derived from Frame 6/1B

- Multi-can DLN1 combustion system with dual-fuel capability for standard/LHE; two-stage turbine with uncooled buckets

- Two-shaft turbine (high-pressure and low-pressure turbines) with variable geometry nozzles between HPT and power turbine

Applications

- LNG

- Pipeline, gas storage

- Refinery, petrochemical, fertilizer

Overview

We have more than 140 units operating worldwide with over 10.4 millions fired hours experience. Our first commercial unit has successfully exceeded 180,000 operating hours.

At ISO conditions with natural gas fuel, ambient temperature 15°C, no inlet exhaust losses, sea level, 60% relative humidity. Inspections can be performed at site. Package dimensions exclude driven equipment.

Fuel flexibility and composition

The Frame 5/2D is capable of operating with a variety of fuel gases with no combustor operability or integrity issues. It can burn heavy hydrocarbons (25% max ethane content or 20% max propane), inerts (25% max CO2 or 25% max N2), and hydrogen up to 20%.

Power crystal life-increase option

An optional extended maintenance plan is available by reducing fire temperature and power—increasing major inspection by 24,000 hours in standard, LHE, and DLN1 configurations with no hardware modifications.

High availability

The major inspection can be performed at site or, optionally, with module replacement to enable production increase, which is ideal in LNG plants.