Reactor instrumentation for the new era of nuclear power

Pioneering nuclear energy

Now, more than ever, nuclear energy is needed to supply the world with reliable, low emissions power. As demand grows, so do concerns about safety and security.

That’s where Reuter-Stokes comes in.

From neutron monitors to traversing in-core probes, mechanical drive equipment and environmental radiation monitors, Reuter-Stokes provides the nuclear instrumentation you need to operate your reactor safely and reliably. And, as nuclear plants apply for life extensions and power uprates, Reuter-Stokes is also your partner for advanced controls, radiation monitoring solutions and comprehensive service agreements.

No matter what your needs in nuclear power generation, we can help. Our local power range monitors (LPRMs), moveable in-core detectors (MIC), in-core and ex-core sensors and accompanying electronics provide quality data, enabling analysis that can result in fewer outages due to equipment failure and the prevention and avoidance of incidents. We are your single source provider for nuclear energy solutions for the 21st century.

Our expertise extends beyond just BWR instrumentation. As the nuclear landscape has grown, so has our portfolio of solutions. Reuter-Stokes can provide the right nuclear instrumentation, radiation monitoring and control solutions to help your plant succeed in the new era of nuclear.

Reuter-Stokes has a comprehensive suite of hardware, software and services to keep your reactor operating safely and trouble-free for its entire lifecycle.

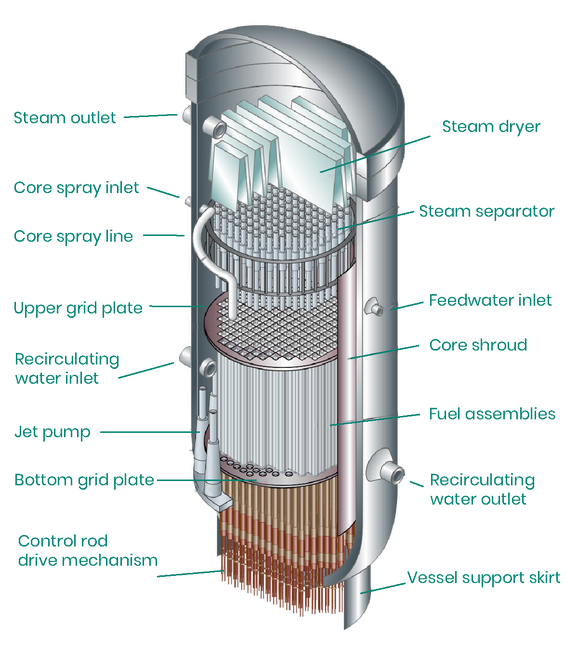

Boiling Water Reactor (BWR)

Advanced BWR (ABWR)

Economic Simplified BWR (ESBWR)

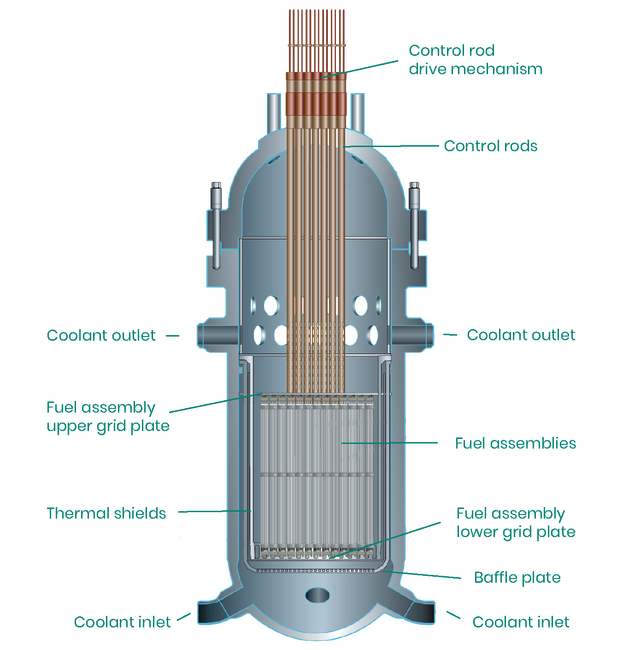

Pressurized Water Reactor (PWR)

Pressurized Heavy Water Reactor (PHWR)

Research Reactor

Reuter-Stokes’ end-of-life analysis ended up saving us two LPRMs. Based on Reuter-Stokes’ analysis of our instruments’ end-of-life calculations, we didn’t need to replace the LPRMs as we had originally thought. This is the first time in 30 years that we were able to start up our unit with all of our detectors in service.

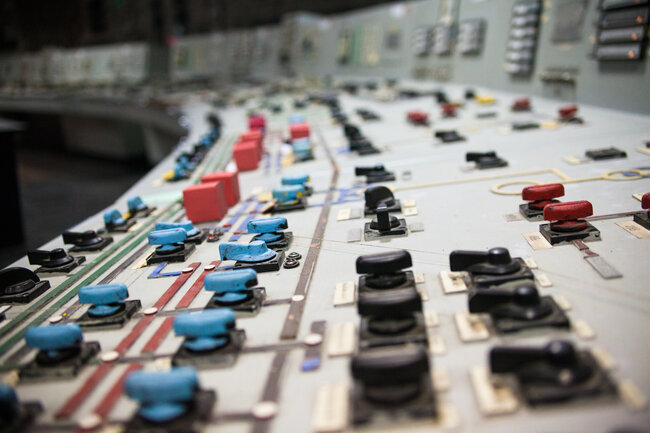

Nuclear instrumentation - the heart of the reactor

Nuclear instrumentation is integral to the functioning of the nuclear power plant. Without monitoring equipment, operators would not have a feedback loop to ensure that the reactor is operating safely and within specification limits. Nuclear instrumentation enables control room technicians to identify the status of the nuclear reactor power output, as well as alerting the control room immediately if the reactor operates outside of normal conditions. When plant availability is crucial, there is no room for downtime.

For such an essential role, you need reliable instrumentation and equipment.

The best technology to keep you positioned for safe and profitable operation

For nearly 70 years, Reuter-Stokes has been designing advanced applications and changing the way energy is produced worldwide. And we continue to invest in technologies to improve the operation of nuclear plants around the globe.

Our nuclear instrumentation also has deep roots. Beginning with the first Reuter-Stokes Helium-3 neutron detector in 1956 that led to the development of LPRMs, we have been committed to excellence in nuclear instrumentation ever since.

Building on our vast success providing sensors and monitoring equipment to BWR customers, we introduced our Moveable In-Core (MIC) detector in 1968 to be used by PWR utilities. Able to map the thermal neutron flux in the water gap between adjacent fuel bundles, our MIC detector has been installed in power plants worldwide. Combining the electronics of reactor controls, we provide a customized, comprehensive solution for all of your BWR and PWR nuclear instrumentation and control needs.

From research and development of the next technology game-changer to improving our existing hardware components and connections, we are committed to innovation. We have deep domain knowledge of your plant, enabling us to provide better, more detailed support.

Designed and built for quality

Beginning with our use of Six Sigma® design and manufacturing methodologies, we make product quality and performance our priority in every step of the process. We incorporate rigorous and extensive testing at all stages of the design, production and pre-installation, resulting in ex-core and in-core hardware that are designed to work reliably.

We perform testing at each major milestone, ranging from materials screening, in-process testing and final evaluation, both onsite and in research reactors around the world. This comprehensive testing methodology contributes to detectors that perform accurately and reliably, improving reactor availability as well as reducing maintenance costs. And with one of the best warranty provisions in the industry, we stand behind our products.

Reuter Stokes’ technical depth and global presence uniquely qualifies us to respond to special customer needs. Whether there is an immediate, unforeseen outage need, or a request for a custom design, Reuter-Stokes can deliver quality products and services, on-time. Examples of custom monitoring instrumentation include:

Installation site constraints

Special material requirements

Disposal concerns

Sensors requiring expertise in pressure boundary design

With thousands of LPRMs installed worldwide, you can trust Reuter-Stokes' nuclear instrumentation to keep your plant running safely, reliably and without incident with our suite of optimization and control solutions.

Partner with an expert

Quality you can count on

BWR

In-Core Fission Chambers

• Local Power Range Monitors (LPRM)

• Source Range Monitors (SRM)

• Intermediate Range Neutron Monitors (IRNM)

• Wide Range Neutron Monitors (WRNM)

• Neutron Traversing In-Core Probes (TIP)

Ion Chambers

• Gamma Traversing In-Core Probes

• Insulated Detectors

• Environmental Radiation Monitors

Movable In-Core Neutron Detectors

• Neutron Traversing In-Core Probes

• Source Range Monitors

• Intermediate Range Neutron Monitors

Associated hardware

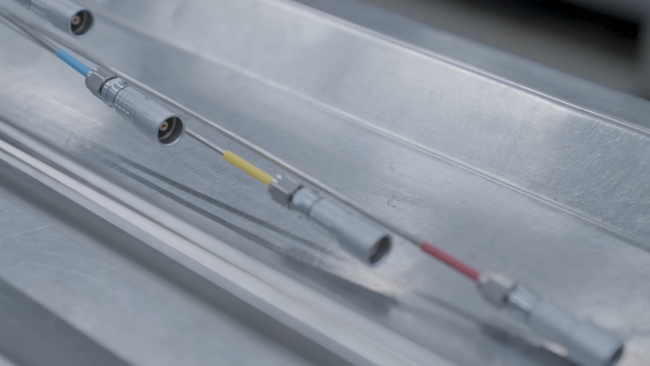

Cables

Connectors

Mechanical

Drive Equipment

Disposal

Equipment

PWR

In-Core Fission Chambers

• Power Range Detectors

• Source Range Monitors

• Intermediate Range Neutron Monitors

• Wide Range Neutron Monitors

• Movable In-Core Detectors

Ion Chambers

• Boron-10 Lined Ion Chambers

• Insulated Detectors

• Environmental Radiation Monitors

Supporting services for nuclear instrumentation

At Reuter-Stokes, we realize the importance of reliability and availability. Every minute lost without producing power means lost revenue. That’s why reducing non-productive time is the primary focus of our services group. Whether it is reducing your outage duration through pre-outage planning and on-site outage support, or promptly troubleshooting your nuclear instrumentation in real-time to keep your reactor running, the goal of our services group is to improve the reliability and availability of your nuclear instrumentation.

We also realize that reliability and availability represent only one half of the equation for profitable growth; operations and maintenance cost is also an important part of plant operations. When offered within the context of a long-term agreement, Reuter-Stokes’ services offering also provides utilities with the benefit of predictable cash flow, a key element in your ongoing cost-control efforts.

Last, but not least, we understand the value you place on knowledge and expertise. As an original equipment manufacturer of nuclear reactors, instrumentation and control systems, Reuter-Stokes is uniquely qualified to offer expert advice to optimize your system performance. Our highly experienced services staff stands ready, not only to tackle the challenges you face today, but also to train and collaborate with your personnel to improve your productivity, enhance your knowledge base and to help you prepare to face tomorrow’s challenges.

Monitoring and diagnostics

End-of-lifetime calculations

Trouble-shooting

System engineering – upgrade or reconfigure

Engineering services

Installation

Post-installation testing

Long-term service agreements

Inventory management

Training

Onsite: customized for your reactor

Classroom: helping ease the transition of personnel turnover

Fully equipped BWR test center

Hands on: functional operation and maintenance

Nuclear Instrumentation: testing and diagnostics

The comprehensive nuclear solution

Boiling Water Reactor (BWR), Pressurized Water Reactor (PWR), and advanced Small Modular Reactor (SMR) projects require experienced partners with the expertise, proven product reliability, and design/manufacturing experience to run their reactors as safely and efficiently as possible. Contact Reuter-Stokes today to talk to an expert about your nuclear instrumentation needs.