Reuter-Stokes’ Flame Tracker delivers success to PSC Yazoo City

The Public Service Commission of Yazoo City (PSCYC) in Mississippi operates a Frame 5 gas turbine that is an essential part of the utility’s combined cycle power plant. Commissioned in 1968, the turbine includes a standard combustion system. The PSCYC utility must prove its readiness and avoid financial penalties by periodically firing up the gas turbine.

However, an attempt to start the turbine proved unsuccessful as the flame sensors failed to detect the flame when lit. PSCYC urgently needed to identify a reliable, consistent, cost-competitive flame sensor source.

Reuter-Stokes’ two

sensor offerings

A flame sensor located inside a turbine compartment must operate under environmental temperatures in excess of 150°C. Reuter-Stokes offers two sensor options to meet this environment:

• Reuter-Stokes’ Flame Tracker with a maximum operating temperature of 150°C, requiring the addition of a water-cooling system in the sensor compartment.

• Reuter-Stokes’ Flame Tracker Dry 325 delivers a maximum operating temperature as high as 325°C, at an increased cost. The FTD 325 capably manages the temperature inside the turbine compartment, with no water-cooling system required.

The Standard Combustion Frame 5 gas turbine has a unique physical configuration that includes only two flame sensors, together on one side of the turbine, with both sight tubes positioned toward the turbine compartment wall.

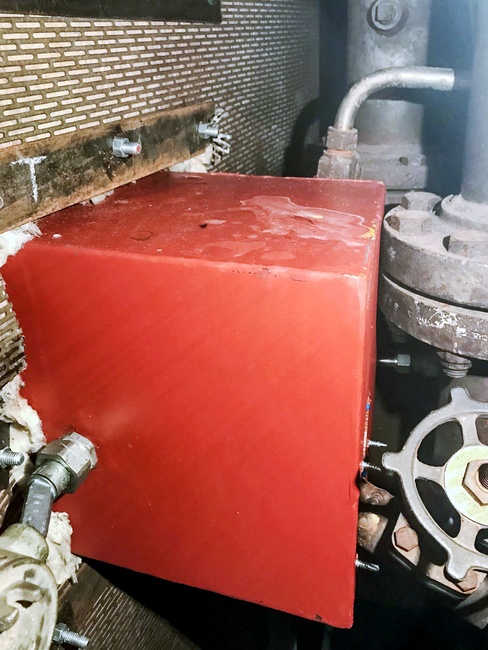

Some Frame 5 Standard Combustion turbines have recessed panels that allow the sight tubes to penetrate the panel wall, with flame sensors mounted in the recessed panels.

This configuration moves the sensor from the turbine compartment’s interior to its exterior. As exterior turbine temperatures are much cooler with a maximum temperature of 85°C, Reuter-Stokes Flame Trackers can be deployed without the need for a water-cooling system.

Reuter-Stokes’ PSCYC solution

Reuter-Stokes proposed the installation of recessed panels for the PSCYC gas turbine. PSCYC designed, built, and installed panels in the turbine compartment wall with Flame Tracker sensors mounted in the panels. The maximum operating temperature of the Flame Tracker is 150°C with the maximum temperature of the exterior environment at 85°C. This simple and innovative approach appealed to the customer because it saved them both time and money while providing a reliable flame sensing solution.

Achieving customer satisfaction

PSCYC’s gas turbine started up twice during the commissioning test, with the satisfied customer declaring it a success. PSCYC can now reliably start their turbine and prove that when mounted in recessed panels, our Flame Trackers provide a successful, reliable, and cost-effective solution for Standard Combustion Frame 5 turbines.

This new cost-effective installation offers the lower cost Flame Tracker option with no water-cooling system needed. Flame Trackers are exceptionally reliable and can be a big improvement over older Geiger Muller-type sensors or other less effective sensing methods.

Reuter-Stokes is pleased to share drawings and installation methods with new customers, including the installation of Flame Trackers on turbines with no recessed panels or turbines that include panels.