Pressure measurement in the Semiconductor Industry

From Chemical Mechanical Polishing (CVD) to Dry Etching, learn how Druck's technology helps chip makers around the world achieve speed, stability and repeatability on pressure measurement and pressure control testing.

There are 2 technologies being used in semiconductor mass flow measurement:

• Thermal distribution

• Differential pressure

Both measurements are pressure sensitive. It means a change in applied pressure will affect the mass flow measurement accuracy. Device makers are using independent pressure sensor to compensate mass flow measurement error induced by applied pressure. It seems that current trend is integrating pressure sensor to mass flow meter or mass flow controller. It is claimed as pressure insensitive mass flow meter or mass flow controller.

The advantage of using pressure sensor in MFC is the response:

With differential pressure measurement, the MFC can achieve the set/targeted mass flow much faster than thermal distribution measurement.

In differential pressure MFC, PID control can be used during flow increase ①, steady state ②, and flow decrease ③.

While in thermal distribution MFC, PID control can only be used during flow increase①.

Deposition process, also known as “Chemical Vaper Deposition”, needs controlling many kinds of gases flow rate (AlCl3, WF6 for IC and GaNfor LED), but it’s mostly used as MFC supported by Thermal MFC without pressure sensors.

However, there is the subject kinds of accuracy at high temp in case of thermal MFC without pressure sensor.

ADROIT6200 provides the accuracy needed for this application.

Precision is key in the dry etching processes for the semiconductor industry. Different uses of dry etching make up the largest subsystem process during chip fabrication.

Druck solutions can be used in different ways during this process to help control pressure in the mass flow controller (MFC) and gas box systems to achieve very accurate gas flow control.

Main applications are: MFC for dry etcher and Gas box system for dry etcher

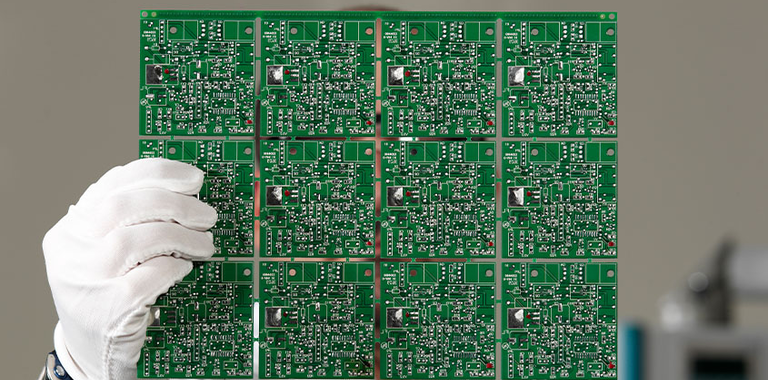

During this part of the process the wafer material is planarized to smooth surfaces through a combination of chemical and mechanical forces. The head of the polisher system needs to be calibrated and maintained in a way that produces fast and repeatable results for each wafer that passes through this process.

Our UNIK5000 configurable sensor coupled with Druck's Pressure Indicator and Loop Calibrator is ideal for constant control of pressure sensor applications to achieve consistent results during this process.

The most common lithography method is optical lithography, also known as photolithography. Photolithography is a fabrication process that patterns parts on thin film or wafer.

Deposition is a method where materials are deposited on a wafer surface as a thin layer.

Both wet and dry etching remove surface materials and create patterns on the surfaces. The main difference is that dry etching is done at the plasma phase and wet etching is done in the liquid phase.

Chemical mechanical polishing uses physical and chemical methods to surfaces of metal for semiconductor manufacturing.