Why flare.IQ for flare management control?

Reducing greenhouse gas emissions has become a major factor in limiting the impact of global warming, this includes methane gas. The oil and gas industry is not the only source of CO2 and methane but it plays a major role in our efforts to reduce greenhouse gas emissions.

Panametrics’ flare.IQ technology helps to monitor, reduce, and control emissions associated with flaring, it can reduce methane slip, minimizes costs from flaring operations, provides steam savings and improves transparency for flare operations.

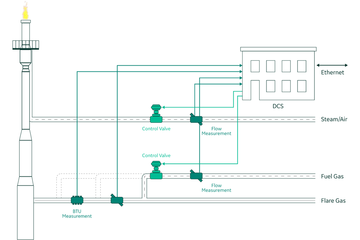

flare.IQ is a full-stream flare solution based on a well-proven ultrasonic flare flow measurement technology. It covers everything including assisted flares associated with downstream petrochemical and refinery flare operations, all the way to unassisted flares associated with upstream operations.

To learn more read our latest technical articles,

Validation of a New Method for Continuous Flare Combustion Efficiency Monitoring

Panametrics flare.IQ technology is offering three options that can be operated independently in any combo:

Helps assisted flares to optimize the combustion at the flare tip by providing setpoints for Fuel Gas, steam and of air assists. Operators can pull critical information about their flare system, including; temperature, pressure, vent gas velocities and gas composition, to calculate the optimum levels of flare performance and ensure 98%+ high-efficiency flare combustion.

Featured

Works on both assisted and unassisted flares: real-time combustion efficiency (CE), destruction removal efficiency and predictive emissions modeling system (PEMS) such as CO2, CO, VOC and CO2eq. Rather than basing reported emissions on static factor of 98%, it is best to report emissions based on the real-time measurement, in compliance with OGMP 2.0 level 4.

Featured

Deploying flare.IQ, operators can also verify flare meters remotely. This helps ensure customers avoid any carbon tax penalties associated with flaring improves efficiency and reduces the health, safety, and environmental (HSE) risk of erecting scaffolding and deploying resources to manually verify flare meters.

Featured

How to accurately measure the amount of steam fed to the flare tip for a smokeless operation is a common challenge among flare stack operators and process control engineers.

Between regulations and a corporate responsibility to improve the environmental landscape, companies are discovering that reliable digital solutions can ease the pressure on control engineers, allowing them to focus their time on maintaining a safe environment for the refinery with reliable data and insights.

To better understand how our flare management systems can help, Panametrics has developed an interactive flare solutions tool that is accessible free online