Flare combustion monitoring system for upstream flares

A novel flare combustion efficiency monitoring method has been developed, using parametric modeling based on existing experimental data and computational fluid dynamics calculations. This method can be deployed to upstream flare systems to achieve maintenance-free real-time monitoring.

CHONG TAO and LEI SUI, Baker Hughes

Flares are open combustion devices for burning off waste and unwanted gas, crucial for emergency pressure relief across petroleum processes across upstream and downstream sectors.

The purpose of burning the waste gas, mainly hydrocarbons and hazardous gases, is to convert them into CO2, a lesser toxic and environmentally impactful gas, compared to hydrocarbons. For example, the greenhouse effect of methane (CH4) is 84 times more than that of CO2 over a 20-year period.

Combustion efficiency (CE), which measures the percentage of hydrocarbons that are completely combusted and converted into CO2 and H2O, is one of the key parameters in the ability to minimize emissions.

Why is it important to ensure complete combustion and conversion of the hydrocarbons?

There are many reasons. From a climate change perspective, operators want to limit the volume of emissions, particularly harmful emissions, such as methane, escaping into the atmosphere and causing long term damage. With ever more ambitious decarbonization strategies there is growing momentum amongst operators to lead the energy transition and significantly reduce their carbon footprints.

From an operational perspective, optimizing combustion efficiency makes good business sense. It generally requires less steam, less energy and therefore less cost.

There are also more stringent regulations on flaring to ensure high efficiency and minimize soot/smoke emissions for the downstream sector because most facilities are located in onshore residential areas. The estimated flare efficiency is 93.9 percent for downstream flares, in contrast to the assumed flare destruction efficiency of 98 percent according to the US Environmental Protection Agency (EPA) studies. [1] For upstream flares, there is no current requirement in monitoring flaring efficiency, which may deviate from the desired flaring efficiency of 98% due to variations of process and environmental conditions. According to the World Bank Flare Tracker, the global gas flaring (mainly natural gas) is around 150 billion cubic meters(bcm) yearly, with the upstream sector contributing 90 percent.[2] When evaluating the environmental impact from upstream flaring, accurate flaring efficiency rather than using the estimated value is critical to prevent methane slip.

Flare CE has been the subject of both experimental and theoretical studies due to its importance in understanding the combustion chemistry as well as the ability of flare systems to effectively burn off flare waste gases. Computational fluid dynamics (CFD) with different combustion models, such as Eddy dispersion concept (EDC) and probability density function (PDF), have been carried out to understand flare combustion mechanisms and factors that influence flare combustion efficiency.

Castineira studied the flare combustion efficiency and emissions using the Laminar Flamelet model, a simplified turbulent CFD calculation. The results match well with turbulent wind tunnel experiments for turbulent flaring conditions. [3]

Singh etc. calculated the CE for both lab scale and industrial scale flares using the EDC turbulence model. Compared to the experimental data from the Texas Commission on Environment Quality (TCEQ) study, the average error in CE for calculated results is only 3.04 percent.[4] Despite the computational cost, progress in CFD has made accurate CE calculation for flaring possible.

Monitoring and measuring industrial flare combustion efficiency has been a longstanding challenge. With the tightened regulations and requirements for flaring, major progress have been made in understanding flare combustion and operations in recent years. One of the most extensive experimental studies was directed by TCEQ in 2010, known as the TCEQ 2010 flare study. Samples of the flare plume were extracted after flare combustion and analyzed using state-of-the-art analyzers to measure the CE and destruction efficiency. As a semi-controlled study where flare operation conditions were contained with uncontrolled ambient environmental conditions, a wide range of operation conditions, test configurations and flare tip designs etc., have been tested and the results were made public available through the Texas state website. [5] This extractive sampling technique is considered the most accurate benchmark method, as it directly measures the flare plume gas. Due to its instrumentation and data analyzing complexity, the sample extraction method is only suited for research and not feasible to commercialize to be employed and used for CE measurement in the field.

One of the more practical approaches to measure flare CE is to use remote monitoring techniques, such as a multi-spectral infrared imaginer which measures unburned hydrocarbons and CO2 concentration in the combustion plume in the mid-infrared spectrum region.[6] Despite its high cost, this camera technique has shown great potential to measure and monitor industrial flare combustion. It demonstrated an average CE measurement error of 0.5% in the 28 test cases comparing well to TCEQ sample extraction results. Being an optical based method, it requires routine maintenance, such as annual sensor calibration and window cleaning, and can be impacted by adverse weather conditions, such as heavy fog/rain and high wind. Smoke from flaring can also interfere with the camera measurement causing excessive errors in CE measurement. For direct measurement, the camera method is a great alternative for periodic flare combustion spot checks.

In this paper, we present a unique method for flare combustion monitoring based on a parametric model that considers all the factors affecting flare combustion efficiency. These factors include the flare vent gas net heating value in the combustion zone (NHVzc), effective flare tip diameter, vent gas exit velocity, crosswind at flare tip and gas composition etc. From the CFD studies and existing test data of flare combustion, all the factors, either one single factor or a combination of several, have shown strong correlation to flare CE. The effect can be described using numeric models. For example, NHVcz is one of the most important factors affecting flare CE as shown in figure 1. The strong correlation between NHVcz and flare CE is the basis of maintaining NHVcz greater than 270 BTU/SCF for refinery flares in the US EPA refinery sector rules (RSR), known as the Maximum Available Control Technology, MACT II, passed in 2015.

One of the major challenges in developing a parametric model of flare combustion is quantifying the interactions of the factors on flare CE. For example, crosswind can significantly impact flare combustion, especially for low flare flow conditions. However, the crosswind effect on flare CE also depends on flare gas NHV, flare gas exit velocity and flare tip diameter, as shown in figure 2.

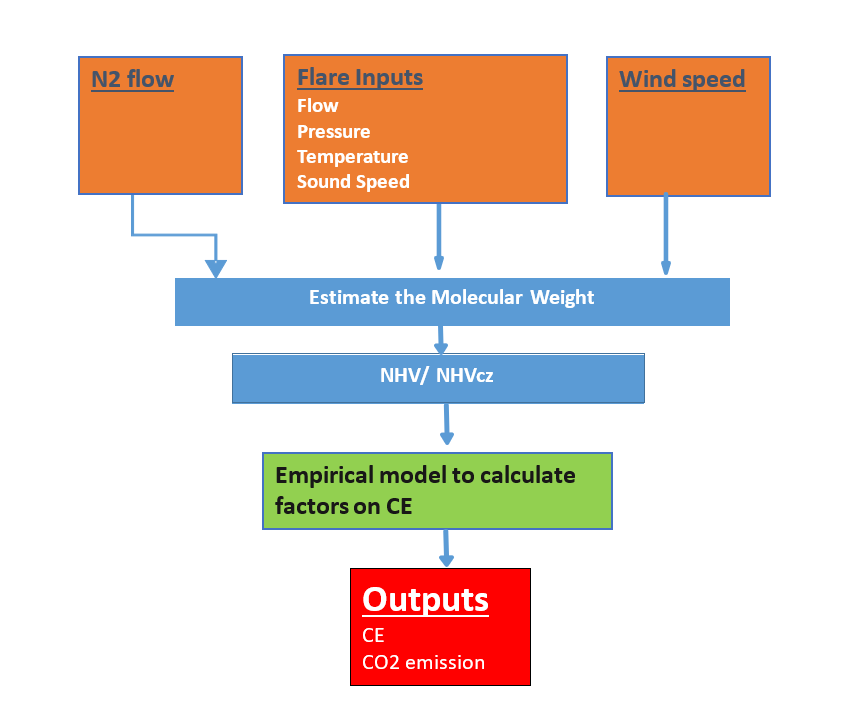

The parametric modeling method utilizing the flare process data, such as flare flow, N2 purge flow and the vent gas molecular weight derived from ultrasonic flow meter sound speed measurement, generates the NHV of flare gas as shown in figure 3. With readily available information on windspeed, gas composition, flare tip diameter etc., an empirical parametric model calculating flare combustion efficiency based on existing test data and CFD calculations has been developed. The overall model error of combustion efficiency in high heating value region (NHVcz > 300 BTU/SCF) is +/-1.05% (absolute value) comparing to experimental data. Based on the combustion efficiency, emissions of unburned hydrocarbon, CO, CO2 and CO2 equivalent can be calculated as shown in Figure 3. This method is particularly suitable for upstream applications as flare configuration is much simpler, usually without any assisted gases and with relatively stable gas composition. With limited instrument updates, such as a common weather station for windspeed measurement, this method can be deployed to any upstream flare system for reliable, accurate and continuous flare combustion monitoring.

This flare combustion monitoring system can be deployed via cloud-based internet or through flare data management systems. It has been tested in the field for upstream flares to achieve real-time, continuous flare combustion efficiency monitoring. Figure 4 shows the field test results of an upstream flare combustion efficiency using the parametric modeling method and the IR camera measurement for six days. Overall, the calculated CE is aligned with the camera measured results, with the exception of the first two days when both the windspeed and flare gas NHV was high. The calculated CE was biased too high for those cases comparing to the camera results, even though the camera performance may also have been negatively impacted by the high windspeed. A key feature of this parametric method is that the parameters can be fine-tuned for a specific flare using reliable test data or flare system specific CDF calculations, so it will be more accurate for a broader range of flare configurations and applications. Periodic calibration with accurate CE measurement can be helpful to verify and improve model accuracy.

The energy transition is gathering pace and the Oil & Gas sector is moving toward a carbon neutral era through various programs, such as Global Gas Flaring Reduction Partnership (GGRP) and Zero routine flares by 2030 initiative etc. However, flaring will continue to be a major source of greenhouse gas emissions in the short term. Flare combustion monitoring is required to accurately measure the emissions, prevent methane slip and evaluate the environmental impact. Any carbon tax or trading system for flaring also requires meaningful and accurate emission measurement. This parametric model of combustion efficiency calculation is the most promising technique for flare combustion monitoring because it’s reliable, accurate and easily scalable across the industry. Combined with the ultrasonic flow meter, where key flare gas information such as vent gas flow, MW and NHV can be derived from the sound speed measurement, the method requires little or no update to hardware for any existing flare systems to achieve continuous flare combustion monitoring.