No water cooling needed!

Hot end operates up to 325ºC

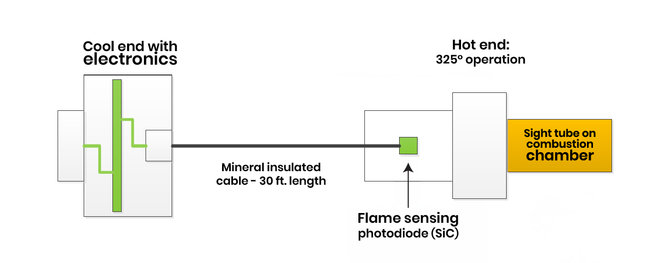

Our Reuter Stokes Flame Tracker Dry 325 senses the ultraviolet (UV) light produced by a flame and signals whether a flame condition exists. This rugged design reduces maintenance by moving sensitive electronics away from the heat, thereby eliminating the need for water cooling. The Silicon Carbide (SiC) optical photodiode is designed for use with multiple fuels, low NOx combustors and steam injection. The Flame Tracker Dry 325 is applicable to a variety of gas turbine models.

High sensitivity, fast response

• Proven SiC technology has high sensitivity to longer UV wavelengths and is not susceptible to black body radiation.

• Rapid response time of less than 0.175 seconds. Similar products may take as long as 1.5 seconds to respond, which creates a potentially undesirable situation.

• Built with the same proven sensing technology that has worked in the Flame Tracker for dec

• Analog output with a wide dynamic range.

• Patented circuitry.

Reduced maintenance

• No water cooling lines, which reduces sensor replacement time and eliminates maintenance of water cooling systems.

• Mineral insulated cable eliminates the need for electrical conduit and the use of fragile fiber optic cable.

• Full operation allowed during the water wash cycle.

• Ready to install, no programming necessary.

Reliable, low voltage operation

• High reliability. Ruggedized construction, high temperature materials, rigorous validation.

• Industry standard output signal (4-20 mA).

• Fuel flexibility—operates reliably with many fuels, with or without steam injection.

• Improved safety through low voltage operation. Eliminates the 350 VDC supply voltage and explosion-proof conduit required by some sensors.

• Ruggedized mineral insulated cable

Customized conversion kits

Designed to replace existing sensors, the Flame Tracker Dry 325 is applicable to a variety of gas turbine models. In addition, it is ETL, ATEX, and IECEx certified.

System configuration

24 VDC nominal, 12-30 VDC @ 100 mA

4-20 mA (a module to convert output to other controller inputs is available)

< 0.175 seconds

Cool end: -51°C to 140°C (-60°F to 284°F)

Hot end: -51°C to 325°C (-60°F to 617°F)

To 400 psig (2.8 MPa)

5 mA @ 1x1010 photons/in2/sec. @ 310 nm

AISI 316 stainless steel

AISI 304 stainless steel

3/4” NPT female

Silicon Carbide (SiC) photodiode