A world-leader at detecting and preventing both missed-trips and false-trips in rotating machinery

3500 Series protection and condition monitoring system is a flexible, scalable platform for continuous, online monitoring of your most critical machinery as well as all other machine assets used in plantwide processes, all available in a single comprehensive system.

Certified for regulatory compliance

The 3500 is designed to fully comply with the American Petroleum Institute’s Standard API 670, the world’s most widely used specification for machinery protection systems. We closely follow the development and changes in these regulatory standards and continually demonstrates our capacity and commitment to be in sync with them as they change and evolve.

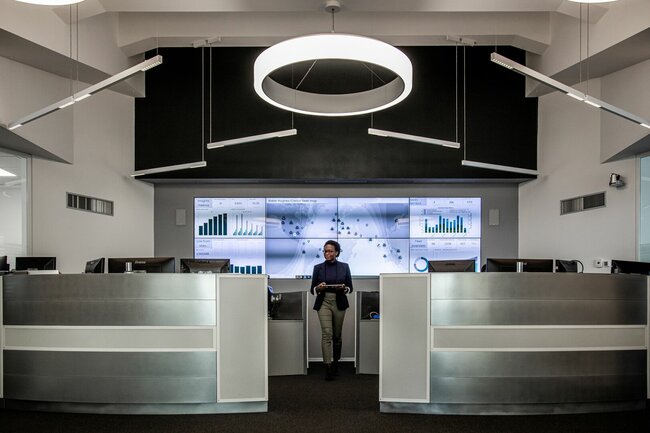

Easily connected for plantwide monitoring

Connecting to condition monitoring and diagnostic software has never been easier. With the 3500 there are no bulky external modules, no additional wiring, and no extra rack slots required. Simply use the Ethernet port in the 3500/22M Transient Data Interface Module and a single network cable to communicate with our System 1 software.

Reliable monitoring system

We understand that our systems are routinely used not just for indication, but to provide auto-shutdown protection. That’s why – even in simplex mode – the 3500 is the most reliable monitoring system we have ever offered with extensive self-checking and fault tolerant design features.

Continuously monitoring critical asset condition is a proven method for anticipating and preventing mechanical failures

The efficacy of our monitoring solutions for protecting your critical production assets have been proven in tens of thousands of industrial facilities around the world.

Understanding the health and operating condition of your process assets allows for advanced maintenance and outage scheduling before serious production interruptions occur.

Avoiding unplanned downtime through a plantwide view of your asset health helps you lower maintenance and repair costs dramatically.

For over 60 years, Bently Nevada has been a trusted brand for industrial condition monitoring

Over 60 years of experience

We have a rich history in helping customers solve industrial maintenance challenges that is over 60 years strong. Through user research in over 20 countries with more than 400 end users, we have studied our customer’s team dynamics, site processes, and technology suites to determine how we can best support plantwide asset health management.

The right expertise, service and support

When you need help, you need somebody responsive. Somebody knowledgeable. Somebody experienced. Somebody that speaks your language. And you need more than one way to reach them—chat, phone, email, Zoom.

- 50+ Global Training Centers

- 500+ Services and support professionals globally

- 18,000+ machinery and diagnostics projects completed