Accuracy under pressure

Hydrology data you can rely on

Overview

Druck’s product range embodies over 50 years of experience designing and manufacturing some of the most accurate and reliable pressure measurement solutions on the market.

Druck’s pressure technologies provide peace of mind that you are getting the reliable data that you need, to make the right decisions to keep your business and equipment running efficiently.

We are one of the only sensor manufacturers to make the silicon sensing element in‑house at our multi-million dollar clean room facility in the UK. As a result, we are able to ensure the highest quality and performance in delivering world class, highly accurate pressure sensors.

Monitoring the quality and quantity of surface and ground water can be categorised into three key areas:

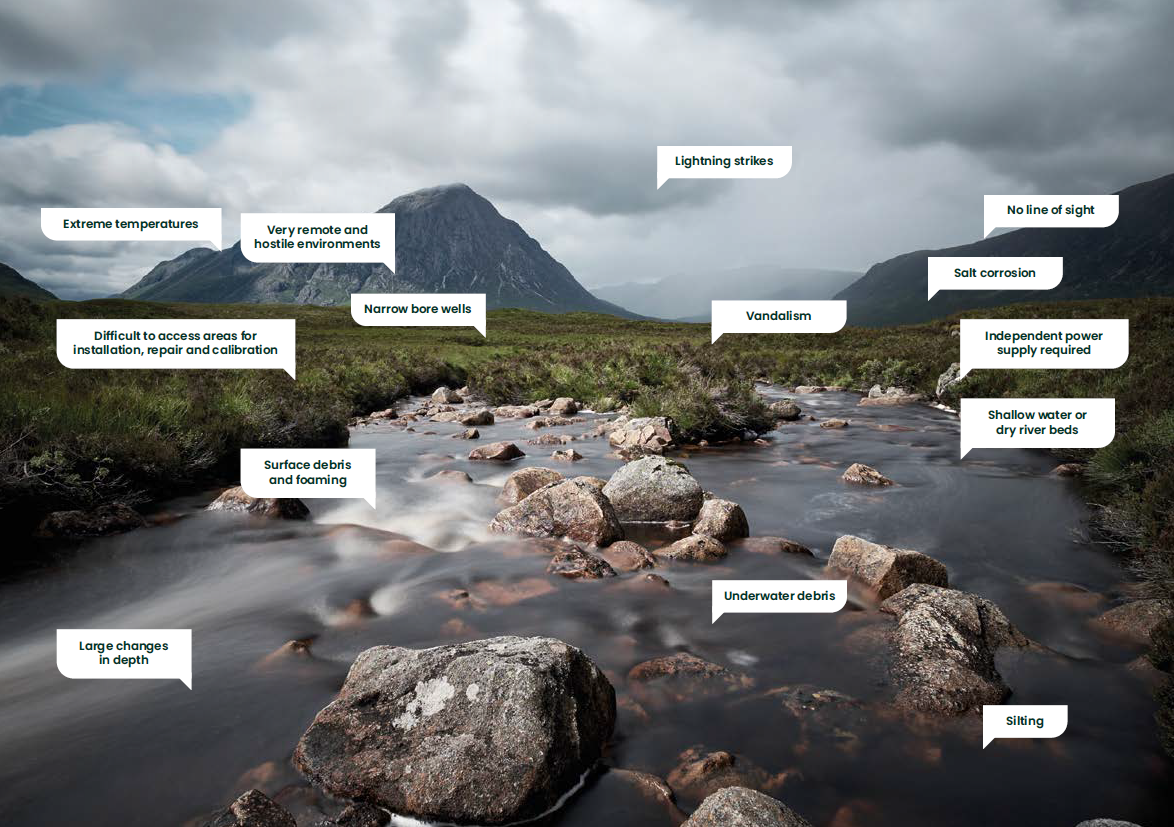

Natural water monitoring

The natural water environment is both hostile and remote. Reliability is critical to quality data collection, particularly when power is in short supply and service is expensive.

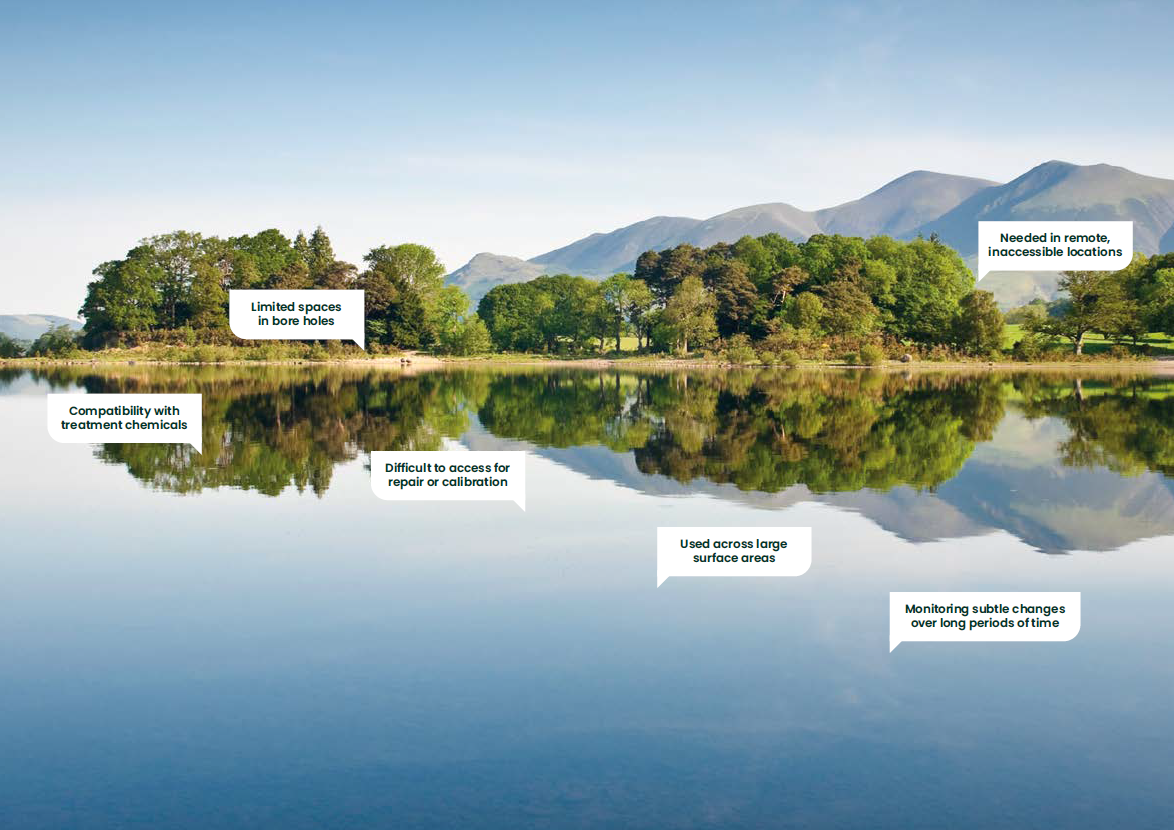

Drinking water

High quality drinking water is a valuable resource. Managing this essential asset requires precision instrumentation across the entirety of the drinking water network.

Waste water management

In waste water management you must have confidence in the durability of your instrumentation. When faced with unpredictable content and a challenging environment, robust construction is key for reliable data collection.

Since 1972, Druck products have successfully applied technological innovation and application focus to a diverse and demanding world of pressure. Our sensor technology has been developed to support some of the most rigorous, challenging and precise applications, making it highly suited for these hydrology applications.

Druck submersible level sensors

PDCR 1830 17.5 mm titanium sensor

PTX 1830 17.5 mm titanium sensor

UNIK5000 25mm stainless steel, highly configurable with depth options

DPS5000 SDI12 25mm stainless steel, digital processing with SDI-12 output protocol

DPS5000 I2C 25mm stainless steel, digital processing with I2C output protocol

RPS/DPS8000 25mm stainless steel, exceptional accuracy and stability with TERPS performance

RPS/DPS8300 25mm Hastelloy, exceptional accuracy and stability with TERPS performance

Level sensor accessories

Druck, for many years, has supplied high quality submersible sensors for applications in the worldwide water industry. Recently, Druck has introduced a new range of special accessories to complement both past and present Druck submersible sensors. The accessories provide a complete system solution, easing problems in installation and maintenance.

These new accessories are compatible with the following past and present Druck submersible sensors.

STE Sensor Termination Enclosure

This sealed “junction box” receives the special “vented” type sensor cable from a Druck sensor and connects to a less expensive, non-vented, proprietary sourced instrument cable.

It allows barometric reference pressure to enter the enclosure while providing a block to water/humidity entering and condensing in the assembly.

Cable clamp

In many surface and ground water applications there has been no easy or cost-effective way to hold a sensor cable at the water exit point, until now.

This clamp secures a sensor cable and prevents the vent tube in the sensor cable from becoming constricted.

The slide mechanism of the cable clamp makes installation an easy task.

Sink weights

Many submerged sensor applications require additional weight to prevent incorrect datum reference due to “cable snake.”

The old solution of strapping lead weights to the cable boot can damage the sensor cable. Druck’s solution attaches sink weights directly to the sensor.

These sink weights match the diameter of the sensor and screw into the front of the sensor. Radial holes around the sensing diaphragm area provide accurate measurement with continuous water circulation maintaining cleanliness.

Calibration adaptors

A regular calibration check is essential to meet local or national quality practices. This requires a level sensor to have a known pressure applied and the output measured.

In the field a portable calibrator can be used with one of the new calibration adaptors to carry out a calibration check.

Independent power supply required

Piezo resistive sensing elements and analogue electronics enable pulse power operation with readings taken in as little as 10 ms. This significantly reduces energy consumption. Voltage outputs reduce current consumptions to a few mA and in short cable run applications, mV output sensors reduce the power on time and current consumption even more. SDI‑12 digital electronics use a standby mode and fast read cycles to keep sensor use to a minimum. This minimises the requirements for expensive batteries or solar chargers.

Difficult to access for repair or calibration

High stability silicon sensing elements in robust packaging ensures accurate and reliable performance over long periods. This minimises the need to visit sites for the repair of faulty components and extends the periods between routine visits for calibration.

Silting

The risk of silting is reduced by connecting the pressure sensing element to the media through a carefully designed pressure port. Soft nose cones both protect the sensing element from physical shock damage and are easily removed allowing access to the open face connectors, which enable gentle cleaning in extreme circumstances.

Debris

Fully welded construction in high quality materials, injection moulded to the thick cable sheathing, ensure both the highest IP rating and reduce the risk of damage from debris moving in turbulent and fast moving water.

Extreme temperatures

The use of high-quality electronic components allow options to accurately measure temperature ranges from -40c to +125c

Salt corrosion

Titanium construction can give you confidence in the long and reliable operation of our sensors in salt water environments, while many years of corrosion free service minimise expensive site visits.

Lightning strikes

By building lightning surge arrestors into the sensor (on the electronics end of the inductance and capacitance of the cable) the best protection in lightning affected areas can be offered. This helps to ensure the longest possible life in the field, thereby lowering the cost of ownership.sits for calibration.

Surface debris and foaming

By measuring the pressure at depth in order to calculate level, Druck pressure based level sensors are immune from incorrect readings caused by surface debris or foaming that will cause errors in line of sight based devices like ultrasonic or radar.

Narrow bore wells

With a sensor diameter as small as 17.5mm, units can be deployed in narrow wells reducing drilling costs. Cable in all models incorporates a Kevlar core which provides strength to allow long cable drops and minimises cable extension under loading. Accessories, link sink weights and cable clamping mechanisms, have been designed to make installation easy and ensure maximum life.

No line of sight

Sloping banks and obstructions like trees make some sites very difficult for line of sight methods. Pressure sensors can be installed in the deepest part of a river with an unobtrusive cable to bring the level information back to instrumentation.

Shallow water or dry river beds

Large silicon sensing elements make it possible to measure depths as shallow as 0.7mm accurately.

This makes accurate level measurement in V notch flow meters possible, where small changes in the water level results in a large change in flow.

Vandalism

Using pressure to measure level is unobtrusive, with much of the equipment hidden underwater. This reduces the instances of installation being damaged by acts of vandalism.

Limited space in bore holes

17.5mm diameter construction reduces the size of bore holes required minimising drilling costs for water extraction. The stiffness of titanium allows narrow body construction without compromising performance or stability. High quality screened cable and 4-20 mA signals are mechanically robust and immune from electro-magnetic interference from electric motors on pumps.

Large surface areas require the highest levels of accuracy

Many new dam constructions have shallow slopes making vertical line of sight technology very expensive to install. TERPS technology allows accurate measurements better than 0.01% (1mm in 10m depth) to allow the most efficient resource management of reservoirs. Digital compensation in our DPS5000 products provides high accuracy when temperatures change.

Monitor subtle changes over long periods of time

Excellent long term stability allows drinking water systems to be accurately monitored. This enables small changes in pressure profiles, caused by leakage, to be quickly seen and located. This can be used to reduce leakage and repair costs.

Compatibility with treatment chemicals

Titanium and stainless steel construction married to cables made of polyurethane or Hytrel enable the best materials to be selected for compatibility with water treatment chemicals. This becomes particularly important in dosing stations or storage tanks where the concentrations can be high.

Difficult to access for repair or calibration

High stability silicon sensing elements in robust packaging ensures accurate and reliable performance over long periods. Accordingly, this minimises the need to visit sites for repair of faulty components and extends the periods between routine visits for calibration.

Inaccessible locations, inspection chambers

Small size, fully welded construction and IP68 to 700m cable connections mean that Druck products give reliable operation in sub surface applications that are prone to flooding. Particularly useful is this feature in differential sensors for use on filters or valves.

Our products are designed to be robust in what can be a violent application where waste can carry heavy objects which can damage level sensors.

Features to cope with this environment include:

• Fully welded construction in stiff titanium or tough stainless steel

• Injection moulding of the electrical cable to the sensor body ensures the IP68 rating is maintained, guaranteeing the integrity of the sensors

• Thick cable walls made of tough polyurethane or stiff chemically robust Hytrel

• Kevlar cable core supply strength – preventing cable stretching.

• Unknown chemicals Titanium or stainless steel metal work with polyurethane or Hytrel cable can be chosen to reduce the risk of chemical corrosion damaging sensors

Silting

The risk of silting is reduced by connecting the pressure sensing element to the media through a carefully designed pressure port. Soft nose cones both protect the sensing element from physical shock damage and are easily removed, allowing access to the open face connectors that enable gentle cleaning in extreme circumstances.

No power available

Piezo resistive sensing elements and analogue electronics enable pulse power operation, with readings taken in as little as 10 ms. This significantly reduces energy consumption. Voltage outputs reduce current consumptions to a few mA and in short cable run applications, mV output sensors reduce the power on time and current consumption even more, which, in turn, minimises the requirements for expensive batteries or solar chargers. Digital electronics use low power standby mode and read cycles to reduce total energy requirements.

Explosive atmospheres

Waste water can release explosive methane. This means that many chambers are designated as hazardous areas. Products used in these areas need to be certified as safe for use. Druck pressure sensor products carry a wide range of certifications for use in such areas allowing installation using different safety rules to suit the application and validity in most countries around the world.

Blocked line of sight and surface foaming

By measuring the pressure at depth in order to calculate level, Druck pressure‑based level sensors are immune from incorrect readings caused by obstruction in tanks or chambers as well as surface debris or foaming that will cause errors in line of sight based devices in ultrasonics or radar.

Used in areas of low pressure

Many waste water applications are in shallow drains where the level of water in normal conditions is very low. Druck pressure sensors use silicon sensing elements made in our own clean room. In order to enable highly sensitive low pressure measurement, particularly in large surface areas, thin elements are used. This makes it possible to measure pressures with a full scale reading as low as 0.7 mH2O (70 mbar, 1psi).

Druck is committed to the future of aviation evidenced by our pressure sensors and calibration solutions. We are an expert engineering company that is ready to partner with you to develop your next project. Contact us today to get started.