Druck Knowledge Base | FAQ | Pressure Calibrators

Find below Drucks knowledge base and FAQ for Pressure Calibrators

If you'd like to contact Druck directly, please click here or email us at druckcontact@bakerhughes.com

For all other FAQ content click here.

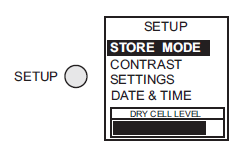

Check the Setup menu to see what batteries are being detected.

If "Dry Cell Level" is shown then the DPI 610 is not detecting that the Ni-Cad Battery pack is fitted, otherwise it would say "Ni-Cad Battery Level"

On the underside of the battery pack there is an additional terminal which the instrument uses to detect if a Ni-Cad battery pack is fitted. This terminal makes contact with the spring terminal in the case base, the terminal is highlighted in the image below.

It seems that the terminal on the battery pack may not be making contact with the spring terminal in the case base. The spring terminal in the case base may need bending slightly towards the battery pack so that it makes better contact with the battery pack.

When the battery pack is making a good contact with the base terminal the instrument will show Ni-Cad Battery Level and not Dry Cell Level in the Setup menu.

The instrument will only charge the battery when the Ni-Cad battery is detected.

The weight of the sensor is approximately 450 to 900 g depending on the configuration.

The specifications on page 5 of the datasheet apply to both the calibrators internal sensor and external/remote sensor (Option B1).

For a range of -1 to +1 bar we calculate the positive direction as ±0.025% FS = ±0.00025 bar.

But for the negative direction we use the Compound Range instead of FS to calculate the specification.

-1 to +1 bar = a Compound Range of 2 bar.

Therefore for the negative direction the specification would be:-

2 bar x 0.025% = ±0.0005 bar

For a range of -1 to +3.5 bar we calculate the positive direction as ±0.025% FS = ± 0.000875 bar.

But for the negative direction the compound range will be -1 to +3.5 = 4.5 bar.

Therefore for the negative direction the specification would be:-

4.5 bar x 0.025% = ±0.00113 bar.

Where we quote the accuracy on the datasheet as 0.025% FS and the instrument has a negative calibration then the specification for the negative direction is ±0.025% of Compound Range.

The specification for the Negative direction is ±0.025% of the Compound Range (-Ve FS plus +Ve FS)

For example if the instrument range was -1 to 20 bar then the Compound Range will be 21 bar.

For DPI 610 external sensors use the part number IO610B-1.

You will need to specify the pressure range and pressure connection on your order.

Calibration will not be required.

All calibration data is stored on the mainboard, just exchanging the display board will not affect the calibration.

NOTE:- We only supply the mainboard and display as an assembly, if this is replaced then calibration is required.

The part numbers are shown on the attached diagram.

The recommended recalibration period is 12 months.

However the instrument has a stability of 0.015% of reading per annum therefore the actual calibration interval will depend on the total measurement uncertainty acceptable for the customers application.

The instrument has lost its software. Return to a GE MCS Service centre to have the software re-installed.

Yes. The same sensor is used in both the DPI 610 and the DPI 610IS.

The sensor is calibrated externally to the instrument on a production calibration rig.

The sensor is calibrated on oil but the front end of the sensor is then washed out to remove the oil.

The sensor is then fitted to the DPI610E Hydraulic Calibrator, pressure testing and leak tests are then carried out using demineralised water.

This may be caused by the button on the Battery Status indicator being permanently in the "on" state.

Check for any signs of damage to the button.

The Battery Status Indicator is not available as a spare therefore the case top will need to be replaced.

Case Top Assembly, part number IS610E-FRONT-ASSY

Note - Having the Battery Status indicator permanently on will not affect the operation of the instrument it will just slightly shorten the time between charges.

Pressure ranges 1 to 20 bar are calibrated from -1 bar to the positive full-scale pressure.

The 350 mbar range is calibrated ±350 mbar.

Ranges of 35 bar and above do not have a negative calibration.

This is due to a bug in the software.

Upgrade the software to V02.00.05 or later.

The software can be downloaded from:- https://inspectionworks.com/druck-portal/#/store/public

The Leak Rate for Pneumatic versions is 50 mbar/min.

For the Positive direction use a wait time of 60 seconds for 20 and 35 bar units, for units less than 20 bar use a wait time of 30 seconds.

The Leak Rate is then measured over the next 30 seconds.

For the Negative direction use a wait time of 30 seconds.

The Leak Rate is then measured over the next 30 seconds.

The Leak Rate for Hydraulic versions is 1.5 bar/min

Use a wait time of 30 seconds.

The Leak Rate is then measured over the next 30 seconds.

Compared to the DPI 610 Leak Test we are using a much shorter wait time so the Leak Rate specification is higher.

On the DPI 610 we used a wait time of 4 minutes and a measure time of 1 minute so we were giving the pressure much longer to stabilise.

We would expect if you use a wait time of 4 minutes you will get a Leak Rate much less than 50 mbar/min.

There is a rechargeable lithium battery which is soldered on the main board that might be not fully charged to hold the date, time and settings.

I suggest you power the instrument using the mains adapter and set the date, time and other settings you require, then leave the instrument powered on longer (i.e 50 hours) to give chance for the lithium battery to recharge. If this lithium cell is fully charged then it should hold the settings when power is removed for up to 30 days.

In the user manual of DPI611 it mention the following.

If the above method doesn't work then the main board is faulty and need replacing.

There is no problem using the power adapter with a DPI 611 that has AA alkaline batteries fitted, protection is in place to prevent the batteries from being charged.

In most cases the Lithium battery used in our instruments will only be powering the Real Time Clock to maintain the Date & Time. The Lithium battery will typically last for 10 years. If at some point after this the battery fails then the instrument will not keep the time and date when switched off, it doesn't mean that you have to replace the PCB.

For the DPI 611 the Real Time Clock is backed up by a rechargeable cell, when used on batteries this is continuously charged until fully charged even with the instrument off therefore the clock should retain its settings. If no batteries are fitted then the cell can discharge, it will last approximately 30 days without batteries. If the instrument is left in storage for a long time without batteries then the date/time may not be retained. It takes approximately 50 hours to initially fully charge the cell.

The procedure below from section 1.13.1 of the DPI 611 user manual K0571 describes how to recharge the clock battery.

There is a bug in release 19R of the DPI 611/612 software that affects the Scaling settings this will be corrected in the next release of DPI 611/612 software.

As as workaround until 20S is released you can downgrade the Application to Rev P (V02.08.05) - Released 25th March 2019

This can be downloaded from the download centre:- https://www.bakerhughesds.com/download-center

There is an issue with the Rev R software in that when the Leak Test Task is enabled the Resolution is not displayed in the Settings menu.

The workaround is to turn off the Leak Test Task then the Resolution can be changed, if need be the Leak Test Task can then be enabled again once the required resolution has been set.

To turn off the Leak Test Task:-

With the Pressure Channel displayed select the Screen Right icon to display the TASK menu.

Select Custom Task -> Pressure -> Utility -> None -> Confirm selection by pressing the tick/check icon twice.

Then access the Settings menu and set the Resolution to the required number of digits.

To access the Settings menu you need to touch the pressure reading, this will expand the pressure reading window, you should then see a cog/wheel icon in the bottom right corner of the display, touch this icon and Resolution should be listed in the menu.

Touch Resolution and you can then select the number of digits to be displayed.

Upgrade the software to Rev S or later version if available.

Typically a change in the reading of approximately 0.00040 bar can be seen.

It should be possible to re-install the DPI 611 software by following the procedure described below:-

Insert a USB stick containing the DPI 611 software into the DPI 611.

Power on the DPI 611 but keep the power button held down.

After a short while the instrument should display:-

"Application Upgrade - Force Application Upgrade? Yes/No"

Select "Yes" and the software should install.

If the power button is held down for too long at switch on, the instrument will go into the Upgrade mode.

The DPI 611 is a little bit slow to power up, but you only need to give a short press of the power button, it may take few seconds for the display to appear but it should power up normally.

The DPI 611 mainboard does not come with the firmware already installed.

You need to copy the firmware to a USB stick, insert the USB stick into the instrument and then power on the instrument. The application (maincode) firmware should then install.

The Settings file on the DPI611 may have become corrupted.

Try the following which will reset the Settings file:-

1. Create an empty file dpi611.reset.

2. Copy this to a USB memory stick.

3. Switch off your DPI611 unit and plug in the memory stick while it is switched off.

4. Power on the unit.

The battery charging time is 6 hours.

When the 20bar abs is used in gauge mode It will become 0 to 20 bar g but you can use it has -1 to 20 bar g

The main thing that will affect the battery life is the intensity of the backlight.

Under normal operation with the settings shown below the running time should be around 12 hours.

The above test but with CH1 set to mA Source, CH2 set to 24V and Display Intensity set to full, the running time was around 6 hours.

Reference document TR1408

Yes, if customer orders a DPI612-PFP-100G then they will receive an IO620-PRV-P5.

This is no longer available, please see attached obsolescence note.

On the DPI 612 it is possible to set the display resolution to 7 digits.

If you were to use a 200 mbar PM620 this would give a display of 200.0000 mbar (the last digit is likely to be unstable).

If you were to use a 20 bar PM620 this would give a display of 20.00000 (again there is likely to be some instability in the last digit).

For the DPI 612 pFlexPro (100 bar model) the internal volume of the pneumatic assembly is approximately 1cc when the Volume Adjuster is fully in (clockwise), when the Volume Adjuster is fully out (anti-clockwise) the volume is approximately 9cc.

When absolute range sensor is connected to the DPI612 it will not allow you to perform zero in either ABS or SG mode. You can zero any offset by using the Tare function. This function can be used in either ABS or SG mode.

Other option is that you can select ABS and then select SG which will show zero reading. If there is a drift on the zero reading then you would need to change back to ABS and then return again back to SG mode. This will zero any drift in the Barometer pressure reading.

The DPI 620 pressure modules are generally not repairable, unless it’s something very minor for example the case is cracked and requires replacing.

Usually if the pressure reading can't be zeroed it's because the zero has drifted by more than the software can compensate for.

The drift is a cumulative value, so even though the zero offset on the display may not be that large the total drift may have exceeded the allowed limits.

If a spare sensor is available then you could try exchanging the sensor and then check if the reading can be zeroed.

If you are using RS232 to communicate with DPI800 then it will only read the current pressure or electrical reading shown on the instrument display.

Therefore answer to your question is NO if it is only displaying 5 digits then it will not show 6 digits through the RS232.

The DPI 800/802 Data Logging Option logs the display, so if the DPI 800/802 has the Mean/Max/Min values displayed then they will be logged.

It is not possible to read the pressure value from the DPI 800 using RS232.

The RS232 cable is used to download data log files from the DPI 800 to a PC.

The DPI 800 has a data logging option that allows you to log the pressure reading and then download the logged data to a PC.

The Data Log option can be ordered as an accessory using the part number IO800E.

You will be supplied with a key/dongle which plugs into the remote sensor socket to enable the option.

For reference the Data Logging user manual is attached.

An alternative product that may be suitable is the DPI 104, this is just a digital pressure gauge. It has an RS232 port that allows pressure readings to be read from the instrument in real time.

Attached is the DPI 104 communication protocol, the DPI 104 datasheet and the DPI 104 user manual.

The part number for the Standard Accuracy internal sensor is IA2975.

You will need to specify the pressure range and pressure connection (G1/8 or 1/8NPT) on your order.

You can use the Scaling Function on the DPI 800/802 to create a "metres of Sea Water" scale.

To Setup the Scaling Function:-

With the pressure reading displayed select the Settings menu.

Next select P1 Pressure and press the Menu/OK key.

From the menu tick/check the box next to "x=y" using the Menu/OK key.

Then press the right hand square key to edit the parameters for P1 Scaling.

NB For reference you can refer to section 1.7 of the User Manual K0335 (see below).

Following "Example 1" in section 1.8 of the user manual edit the Label for the x=y scaling to show "m Sea Water" or a similar label.

Then following "Example 2" from the user manual edit the upper and lower Scaling parameters.

For the Lower parameter - set 0 bar = 0 meters of Sea Water

For the Upper parameter - set the instrument full-scale in bar = the equivalent pressure in metres of Sea Water.

Confirm the settings using the Menu/OK key

Press the Esc key to return to the main display.

The instrument should now display the Scaling Function "m Sea Water"

To turn off the Scaling function:-

Select the Settings menu

Select P1 using the Menu/OK key

Un-tick/Un-check the "x=y" Scaling function using the Menu/Ok key.

Press the Esc key to return to the main display.

The DPI800/802 manual isn't available on CD only hard copy. Attached is the PDF format of the manual which you can burn onto a CD or copy onto a memory stick.

To over-ride an unknown pin use the pin 0800 followed immediately by pressing the HOLD key. NOTE:- This applies to all models within the DPI 800 series.

The display updates at two times per second (response time = 0.5 sec).

This is likely to be caused by a bug in the instruments firmware. Check the status menu to see what version of firmware (DK246) is installed. If the firmware is older than V06.04.03 then it will require upgrading to the latest version. NOTE:- This applies to all variants of the DPI 800 series apart from the DPI 880