2024 Offshore Technology Conference Spotlight on New Technology Award Winner!

Highlights

Benefits

- Set liner hanger and release tools quickly and deliberately by initiating command from surface

- Optimize operations by knowing the right information at the right time, removing uncertainty

- Set hanger any time before, during, or after cementing and collect data to determine top of cement

- Continuously rotate pipe while cementing to ensure cement coverage for well integrity

Applications

- Extended-reach wells

- Narrow-margin wells

- Liner drilling

- Multistage cementing

- Managed pressure drilling

- Cemented scab liners

Overview

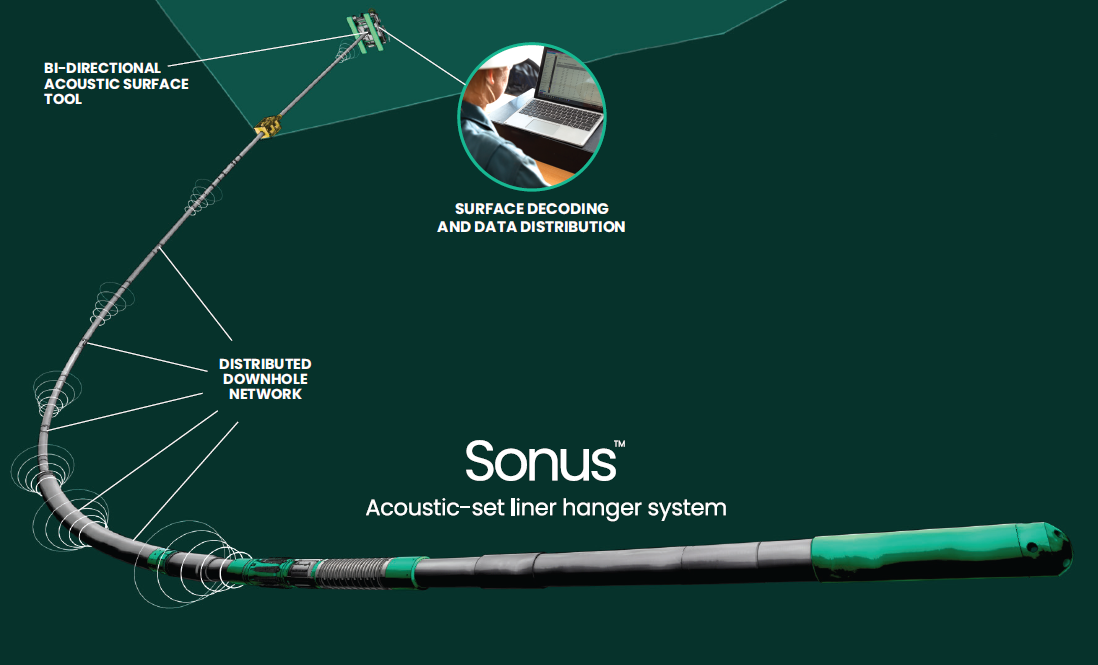

The Baker Hughes Sonus™ acoustic-set liner hanger system delivers a new way of installing liner hangers that saves time, optimizes operations, and reduces risks. Enabled by the Baker Hughes XACT™ bi-directional downhole acoustic telemetry platform, the Sonus system not only delivers real-time downhole data throughout the entire liner installation, but also includes a downlink mechanism to selectively actuate your equipment before, during, or after cementing.

NO WAITING

With the Sonus system, you decide when and where to set the hanger - no delays. Unlike conventional methods, this system sets the liner using a discrete acoustic command signal sent quickly and deliberately from the surface down the drill string to selectively set the liner hanger or release the running tool.

Reduce NPT

• Using acoustic signals eliminates the need for weights, hydraulics, or balls – so you don’t need to wait for confirmation that the liner is set

• Set hanger any time before, during or after cementing without hydraulic cylinders or predetermined running tool configurations

• Avoid errors with a robust acoustic command sequence coded to eliminate accidental setting

NO GUESSING

Once the liner is set, the Sonus system collects key data like pressure, temperature, and torque, and sends it back up the drill pipe in real time. This on-demand data lets you make split-second decisions and take action with confidence to optimize your operations.

Operate efficiently

• Execute more aggressive running-in-hole and circulation events

• Diagnose and resolve events rapidly

• Minimize NPT and ILT Streamline cementing

• Get all the data you need in a single trip, with a single technology

• Continuously circulate mud prior to cementing to eliminate the collection of mud solids

• Rotate and/or reciprocate during cementation with the same hook-up to ensure zonal isolation

Streamline cementing

• Get all the data you need in a single trip, with a single technology

• Continuously circulate mud prior to cementing to eliminate the collection of mud solids

• Rotate and/or reciprocate during cementation with the same hook-up to ensure zonal isolation

NO COMPROMISES

Because the Sonus system provides an all-in-one solution, compromises are eliminated – there are no ball seats, no limits on circulation, and compatibility is limitless. And you can get operational flexibility with on-demand tool actuations, instead of limited pre-set configurations. Since the setting and releasing mechanism are both independent of the hydraulic operations, you can be well-equipped and ready for any and all configurations without the need to change out tools. This means:

• The tools are ready to go for all operations, all the time

• You don’t need to spend time reconfiguring equipment - especially helpful in deepwater operations

• You don’t have to compromise on which tools to optimize for one operation at the expense of another

HOW SONUS WORKS

A wireless command is sent from a surface laptop to the bi-directional acoustic surface tool, which sends an acoustic command down the drillstring through the XACT communication network. The XACT tool closest to the liner hanger then sends a highly robust acoustic signal to initiate setting. Within the liner hanger, a robust spring mechanism provides the setting force while a bearing allows for rotation after it is set. Next, a separate command is sent to release the running tool. The Sonus ARD-E acoustically actuated running tool provides on-demand release capabilities independent of pressure or pipe manipulation so you can run it when and where you want before, during, or after cementing. Before and after setting the liner, the XACT tools continuously transmit downhole measurements like pressure, weight, and torque. The downhole and distributed data can be used to provide more information about the cementing operation to help determine top of cement.