Highlights

Benefits

- Provides quality DAS measurements at distances previously thought impossible

- Permits customization of individual applications for optimum overall signal performance

- Enables wavelength measurement customization through on-the-fly adjustments

- Offers superior backscatter enhancement through a proprietary fiber with scatterers written into the silica

- Eliminates hydrogen darkening for long-term reliability

Applications

- Deepwater wells with long step-outs

- Carbon capture, utilization, and storage (CCUS) wells

- High-temperature wells

- Wells with high levels of hydrogen

- Vertical seismic profiling

- Flow profiling

- Leak detection

- Sand detection

Overview

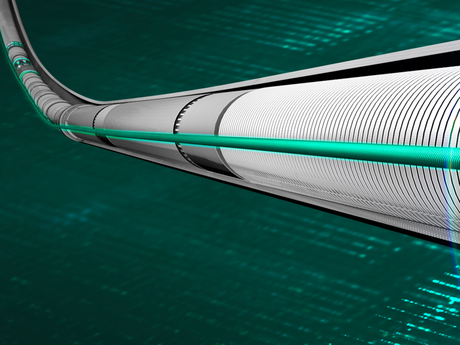

Baker Hughes SureVIEW™ CoreBRIGHT™ enhanced backscatter fiber (EBF) leads the industry in scatter performance, allowing operators to take quality DAS measurements at distances previously thought impossible.

CoreBRIGHT EBF is constructed with a proprietary in-house manufacturing method that provides the industry’s best protection against hydrogen darkening.

HIGHLY FLEXIBLE

SureVIEW CoreBRIGHT EBF is available with the industry’s strongest scatter enhancement, outperforming other fibers by up to 100X, yielding unprecedented optical signal-to-noise ratio. This enhancement can be tailored to individual applications to provide the optimum overall signal performance. Testing has concluded that SureVIEW CoreBright EBF is also the best all-around fiber and has been demonstrated to overcome subsea step-outs of up to 90km without introducing complexities to subsea infrastructure, while providing long-term reliability within the wellbore. In seismic and micro-seismic dry-tree applications where long step outs are not an issue, using CoreBRIGHT EBF still significantly improves measured strain sensitivity, resulting in better signal fidelity and faster acquisition times. Baker Hughes balances the optical losses, scatter enhancement, and hydrogen sensitivity to meet the exact needs of your unique application. Based on the specific well criteria, Baker Hughes can tune the EBF for optimized DAS measurement, to account for:

• Long step-outs

• Hydrogen sensitivity

• DAS sensitivity

• Different DAS interrogators

Because of this flexibility, CoreBRIGHT EBF can be customized to work with any interrogator that’s best for your application. And, because CoreBRIGHT doesn’t require your scatterers to be placed at fixed parameters, you can further customize wavelength measurements through on-the-fly adjustments, improving your measurement accuracy in:

• Vertical seismic profiling

• Flow profiling

• Leak detection

• Sand detection

LONGER LASTING FIBER

SureVIEW CoreBRIGHT EBF uses CoreBright optical fiber, which leads the industry in hydrogen darkening resistance— the primary cause of failure for fiber optic systems in high temperature applications. Where others use dopants, such as germanium, which can create fiber imperfections, CoreBright fiber is made from pure silica glass, making it immune to hydrogen darkening. Because Baker Hughes designs and manufactures CoreBRIGHT EBF in-house, the fiber can be tailored to individual applications to provide optimum overall scatter performance.

A BETTER SIGNAL

Fabricating a downhole optical cable with the performance and reliability demanded by the oil and gas industry requires a sophisticated understanding of fiber design, fiber coatings, cable manufacturing processes, and cable construction. Optical, chemical, and physical disciplines have been combined with extensive oilfield experience to offer a superior proprietary cable with scatterers placed into the silica for backscattering enhancement. This proprietary technique yields the best signal enhancements in the industry, while preserving low optical loss. When combined with the SureVIEW™ sDAS interrogator and Baker Hughes best in class installation services, SureVIEW CoreBright EBF provides maximum DAS performance. Whether it is for conventional dry-tree applications where data quality is critical, or for ultra-long stepout subsea wells, CoreBRIGHT EBF provides a unique solution for distributed acoustic sensing.

HOW IT WORKS

SureVIEW CoreBRIGHT EBF increases light transmission through a glass structure featuring carefully placed small mechanical and chemical features that generate a large range of backscatter, or reflected light. In typical solutions, the fiber usually interacts with hydrogen, reducing the amount of backscattered light and rendering it un-useable after some time. SureVIEW CoreBRIGHT EBF prevents this interaction with hydrogen by getting rid of chemical impurities in the glass structure, virtually eliminating hydrogen darkening through the use of pure silica glass. The backscatter of light in CoreBRIGHT EBF is amplified through the interaction with reflecting points with known characteristics and locations to improve optical measurement performance even in long distances.