Overview

The absence of accurate, reliable data in any artificial lift operation equals significant operational risks and may inhibit wells from producing at optimal rates. Lack of information leads to improperly sized pumping systems and can catch you off-guard to problems until you see a decline in production rates or the artificial lift system fails. Given the current environmental challenges of mature wells, an increasingly harsh operating environment, and widespread cost control mean you absolutely must know the downhole condition so you can enhance performance and well productivity.

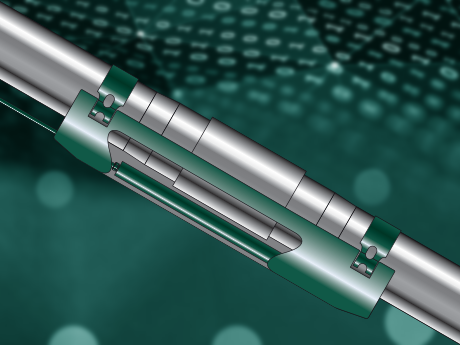

To gather crucial downhole information, a continuous stream of reliable well and pump condition data is critical for assessing artificial life system performance and effective well management. Our Zenith™ C-Series gauges are available in multiple specifications to suit your individual application and are designed to provide continuous data, even in difficult high temperature environments up to 752°F (400°C). In addition, the permanent reading of annulus pressure enables improved control of well drawdown, maximizing your production while keeping pressure and fluid level above critical pump off conditions. Advanced parameters intelligently analyzes issues that decrease lift system run life, permitting preventative maintenance and effective workover management.

A reliable well surveillance system pushes the artificial lift system to achieve optimum output—safely. Knowledge gained from real time, direct measurements enables you to reach optimum output and to maximize performance while ensuring the pump is protected. With around 3,000 systems installed globally, a heritage of reliability and engineering excellence, the Zenith C-Series gauge provides you a proven and dependable solution.