Overview

Our X-Treme Clean™ EP wellbore cleanup and displacement system decreases completion and workover risk in land, shelf, shallow water, and deepwater applications. We’ve used this reliable system successfully in more than 2,500 jobs worldwide, including many remote locations.

A reliable solution to complex projects

You can rely on this solution in complicated projects, such as high-pressure/high-temperature (HP/HT) wells and those with chrome casing.

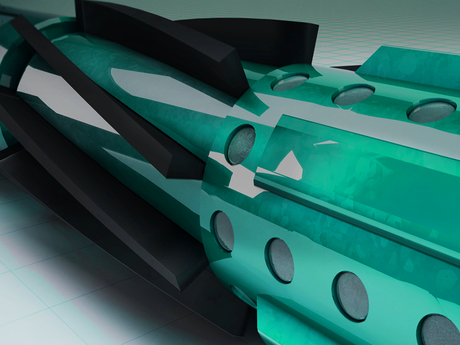

The nonrotating technology of the tools efficiently cleans while minimizing potential damage to the casing or riser inside diameter (ID). High allowable rotational speed with a large total flow area offers more effective well cleaning and displacement, especially in deviated wells.

If the bottomhole assembly (BHA) becomes stuck, you can activate our industry-exclusive scraper and brush clutch design to free the BHA for even greater reduced operational risk.

The tools can be used, during the pre-completion stage, completion stage, or workover stage, as an integrated system or individually for displacement, casing ID cleaning, riser and blowout preventer (BOP) cleaning, fluid filtration, downhole junk removing.