Highlights

Benefits

- High availability thanks to a mean time between maintenance of 32,000 factored fired hours or 1,300 factored fired starts

- Capable of single-digit NOx emissions

- Wide flexibility for gas and liquid fuels; syngas option; low emissions, grid support, peaking, cyclic and base load modes

Features

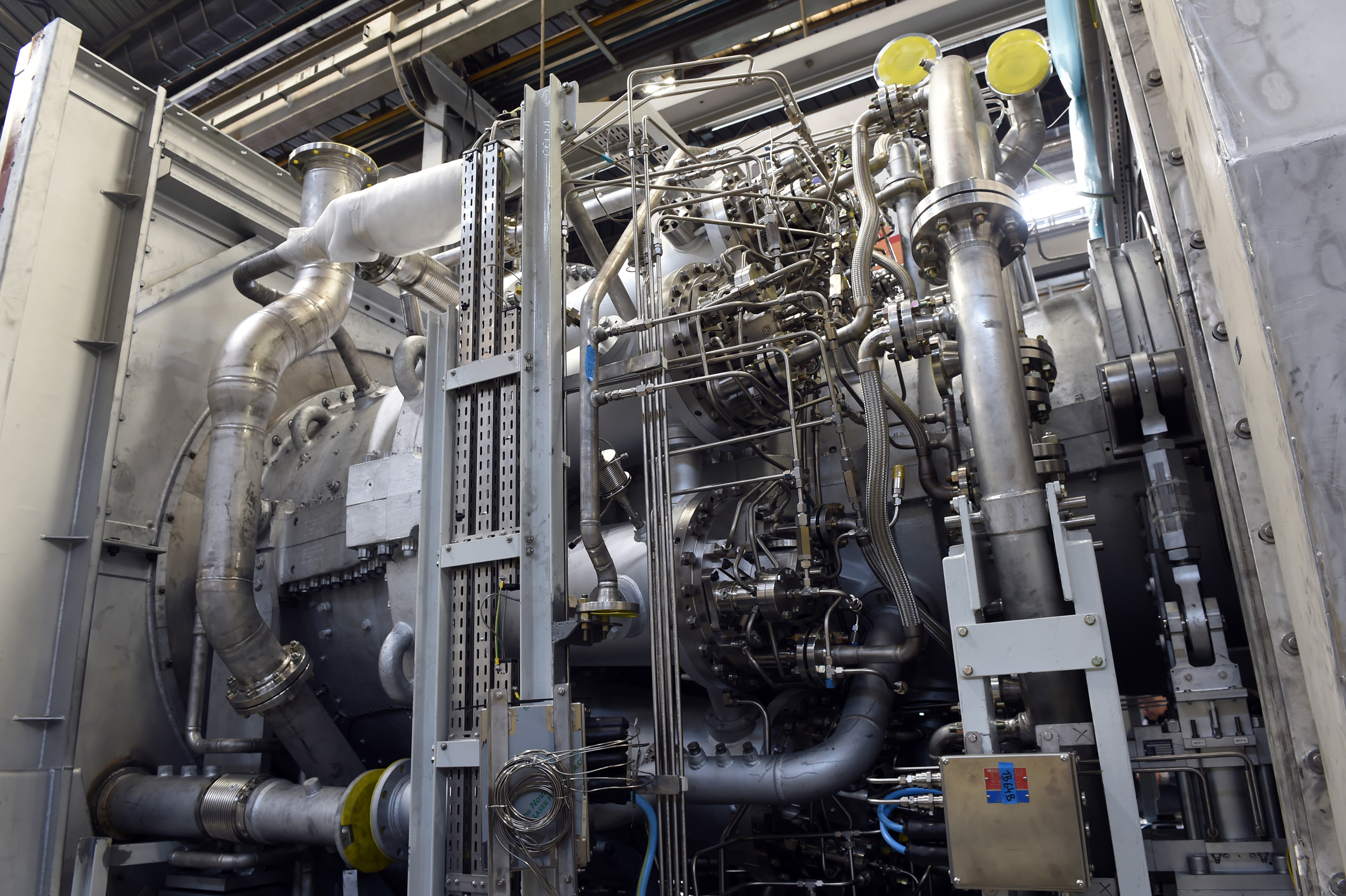

- Single-shaft engine with hot-end drive, 17 axial compressor stages, 12.7:1 pressure ratio

- 10 combustion chambers with reverse-flow STD/DLN1+ combustion system (single-digit NOx emissions)

- Three turbine stages with air-cooled first and second stage nozzles and buckets

Applications

- Simple cycle and cogeneration

- Combined cycle (with steam turbine)

- LNG

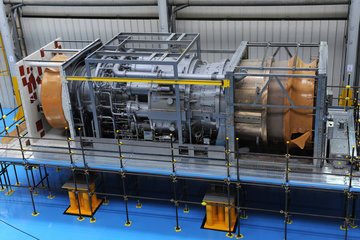

The Frame 6/1B turbine is appropriately sized so output and exhaust energy fit electricity and industrial steam demand, integration in an island network for power generation, and in an industrial complex for cogeneration. Its modular design is ideal for meeting unique site layout constraints.

DLN1+ specification. At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Package dimensions include driven equipment.

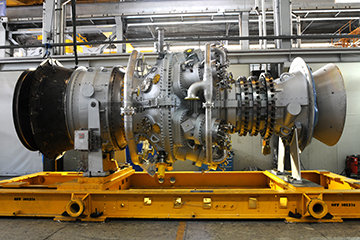

Proven

With more than 1,150 units installed worldwide, the Frame 6/1B provides proven energy efficiency, availability, reliability, and maintainability.

Fuel flexibility

It can operate on natural gas, LNG, distillate, and treated residual oil in a variety of applications. For a standard combustor, the turbine can burn up to 100% H2. Depending on the combustor and H2 quantity in the fuel, NOx levels with water or steam injection range from 25 ppm to 65 ppm.