Highlights

Highlights

Benefits

- Pull tubing into long tortuous wells while eliminating the need for friction-reducing chemicals

- Ensure better hole cleaning in fewer trips

- Reduce plug milling time

Applications

- Composite bridge plug and ball seat milling

- Fishing services and coiled tubing pulling

- Acidizing and scale removal

Overview

Overview

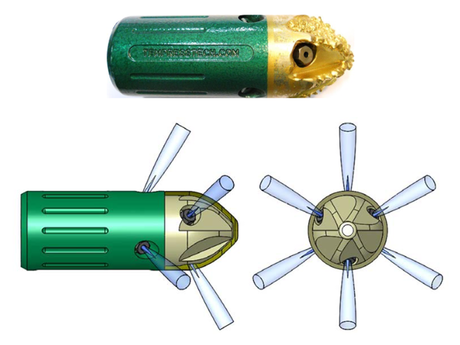

Get proven, powerful friction-breaking to optimize your well intervention operations with the Tempress HydroPull™ tool from Baker Hughes.

Get assured friction reduction in your longest laterals

The Tempress HydroPull tool incorporates a cycling valve that momentarily interrupts the flow to create water-hammer pressure pulses inside coiled or jointed tubing used in horizontal well interventions. This water-hammer effect also generates suction pulses that pull the tubing into the well at a rate of 20 ft/min (6 m/min) or more.

These periodic pulses also vibrate the tubing, which reduces friction drag and extends the lateral reach of the tubing by delaying the onset of helical buckling and lockup.

The HydroPull tool continues to set and break all existing records for extended reach applications. The powerful pulses can effectively double the horizonal extended reach of your coiled tubing well interventions. In the field, the fluid hammer generated by the HydroPull tool has delivered excellent weight on bit in horizontal laterals up to 26,853ft (8,185m).

The HydroPull tool is typically run above a downhole motor for milling applications. The tool is fully tunable for various impact levels and custom applications.

Contact us to learn how the Tempress HydroPull tool can optimize intervention operations in your extended-reach wells.