Highlights

Highlights

Benefits

- 36.8% efficiency in mechanical drive; up to 84% thermal efficiency in combined heat and power

- Flexible operation to 50% of rated speed; ideal in mechanical drive—can start with fully pressurized compressor

- Lower maintenance costs and 35,000 hours MTBM—automapping eliminates seasonal DLN tuning and intermediate boroscopic inspections

Features

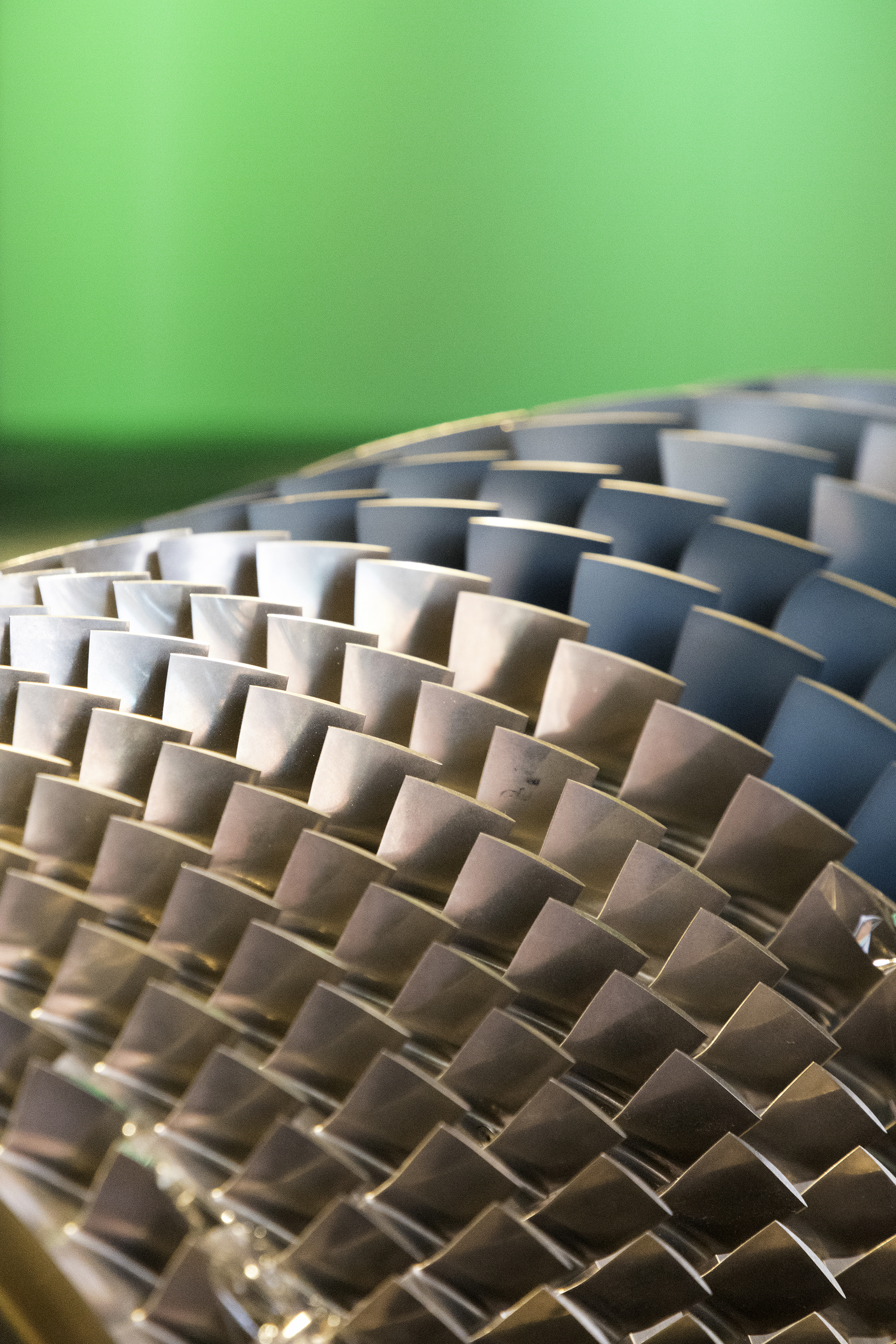

- Rugged, high-performance axial flow compressor

- Single-row annular combustion system for best-in-class low emissions and wide fuel flexibility

- Highest efficiency over the entire power range thanks to variable-geometry, low-pressure turbine nozzle technology

Applications

- Onshore and offshore

- Pipeline, gas storage

- Industrial, and combined head and power

Featured Videos

Overview

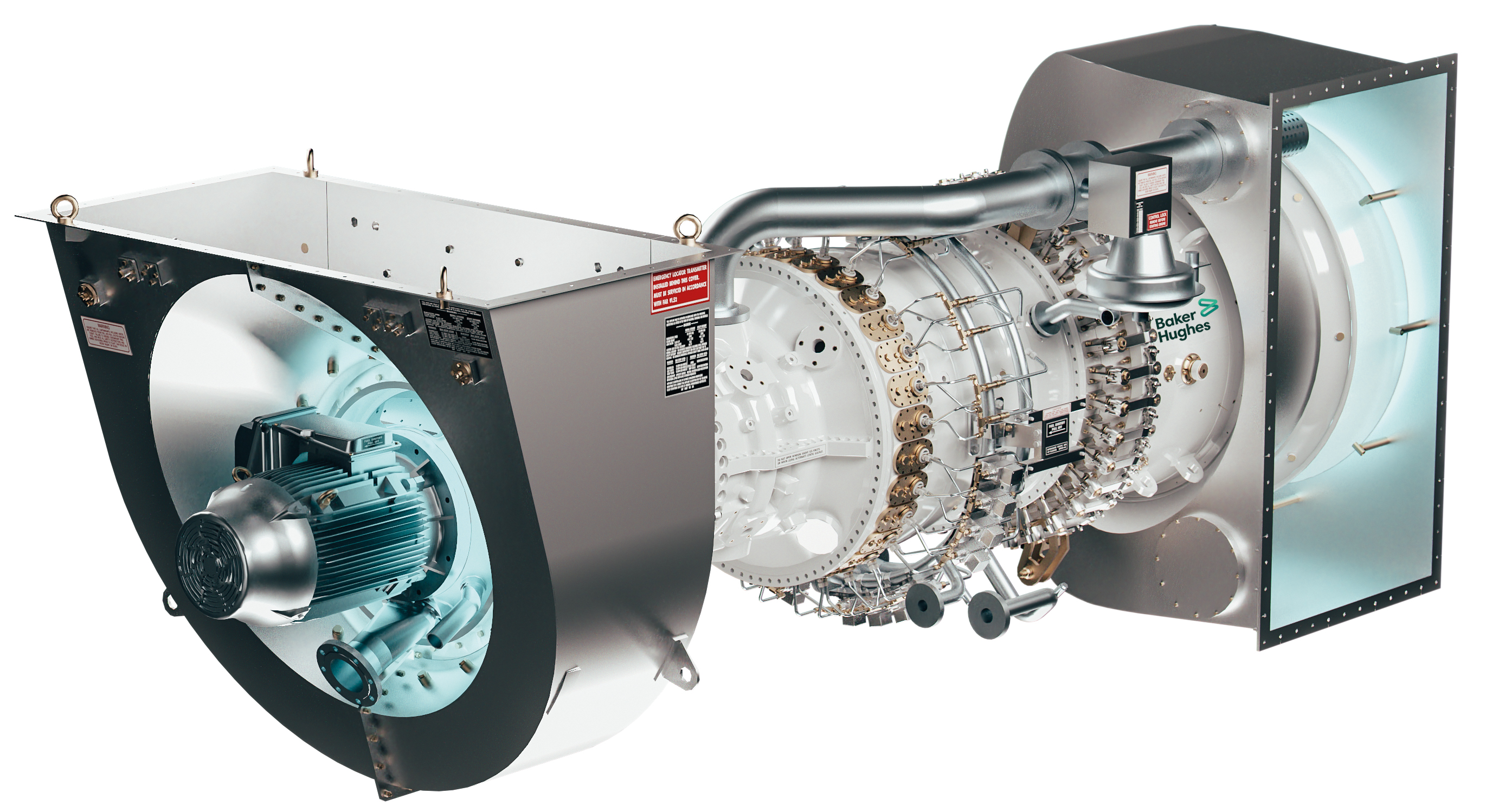

The NovaLT™12 gas turbine draws on our latest innovations combined with the best proven technologies and fleet experience from our entire gas turbine portfolio.

Specification

Mechanical drive

Power (MW/HP)

13/17,400

Efficiency (%)

36.8

NOx emissions (ppm)

15*

Exhaust temperature (ºC/ºF)

496/924.8

Speed (rpm)

4,450-8,900

Hot gas path inspection

35,000

Major inspection

70,000

Package dimensions (m/ft)

8.8x2.5x3.5/28.9x8.2x11.5 (LxWxH)

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Package dimensions exclude driven equipment.

* 9ppm upon request

Specification

Power generation (50/60 Hz)

Power (MW)

12.5

Efficiency (%)

35.3

NOx emissions (ppm)

15*

Exhaust temperature (ºC/ºF)

496/924.8

Speed (rpm)

4,450-8,900

Hot gas path inspection

35,000

Major inspection

70,000

Package dimensions (m/ft)

14.3x2.5x3.5/46.9x8.2x11.5 (LxWxH)

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Package dimensions include driven equipment.

* 9ppm upon request

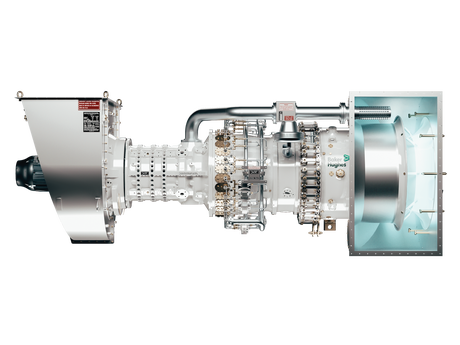

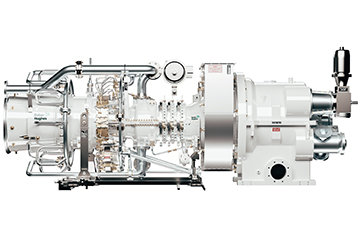

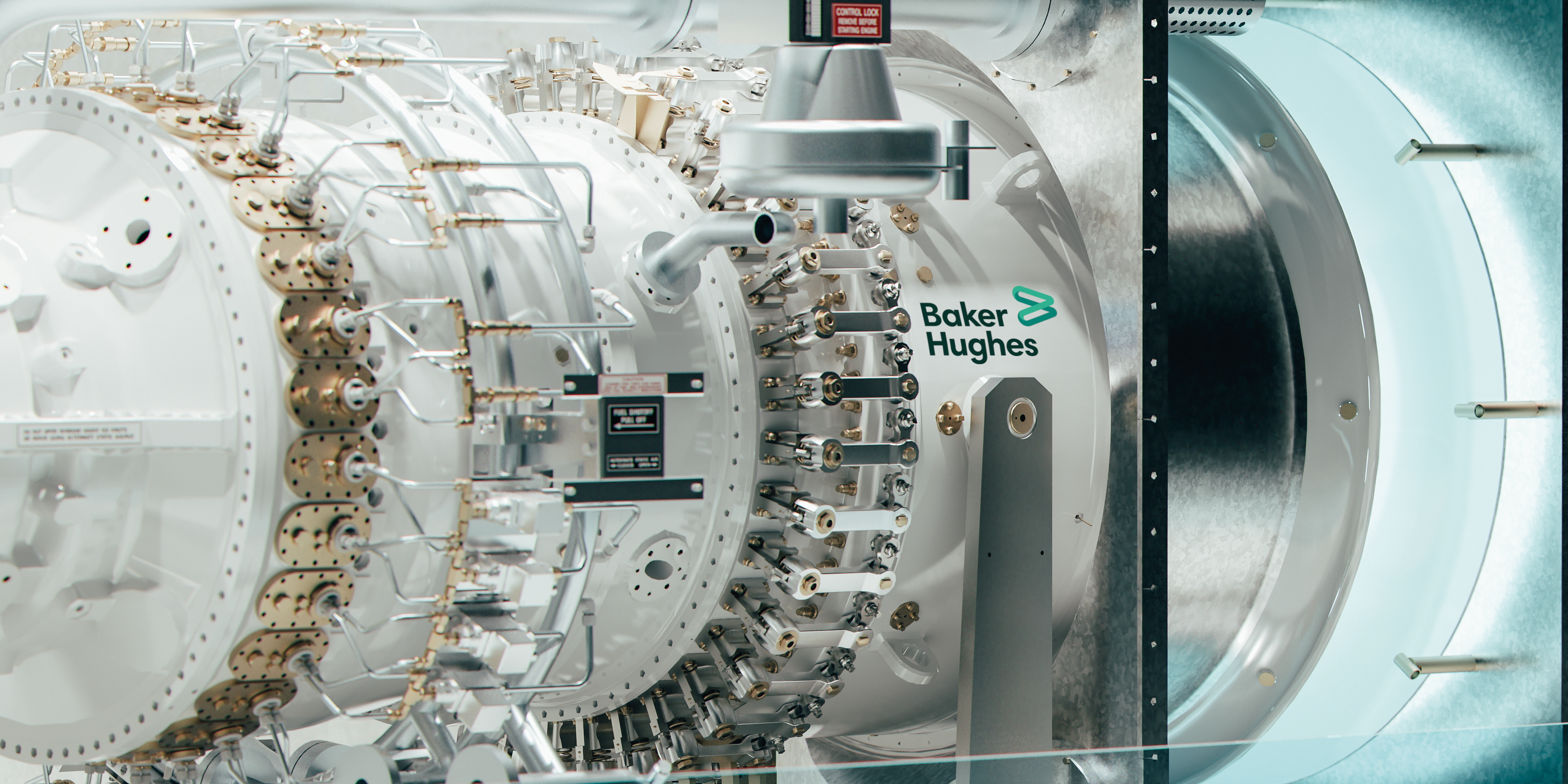

The best from two worlds

NovaLT™12 gas turbines blend the robustness of our frame technologies with the modular maintenance capabilities of our aeroderivatives.

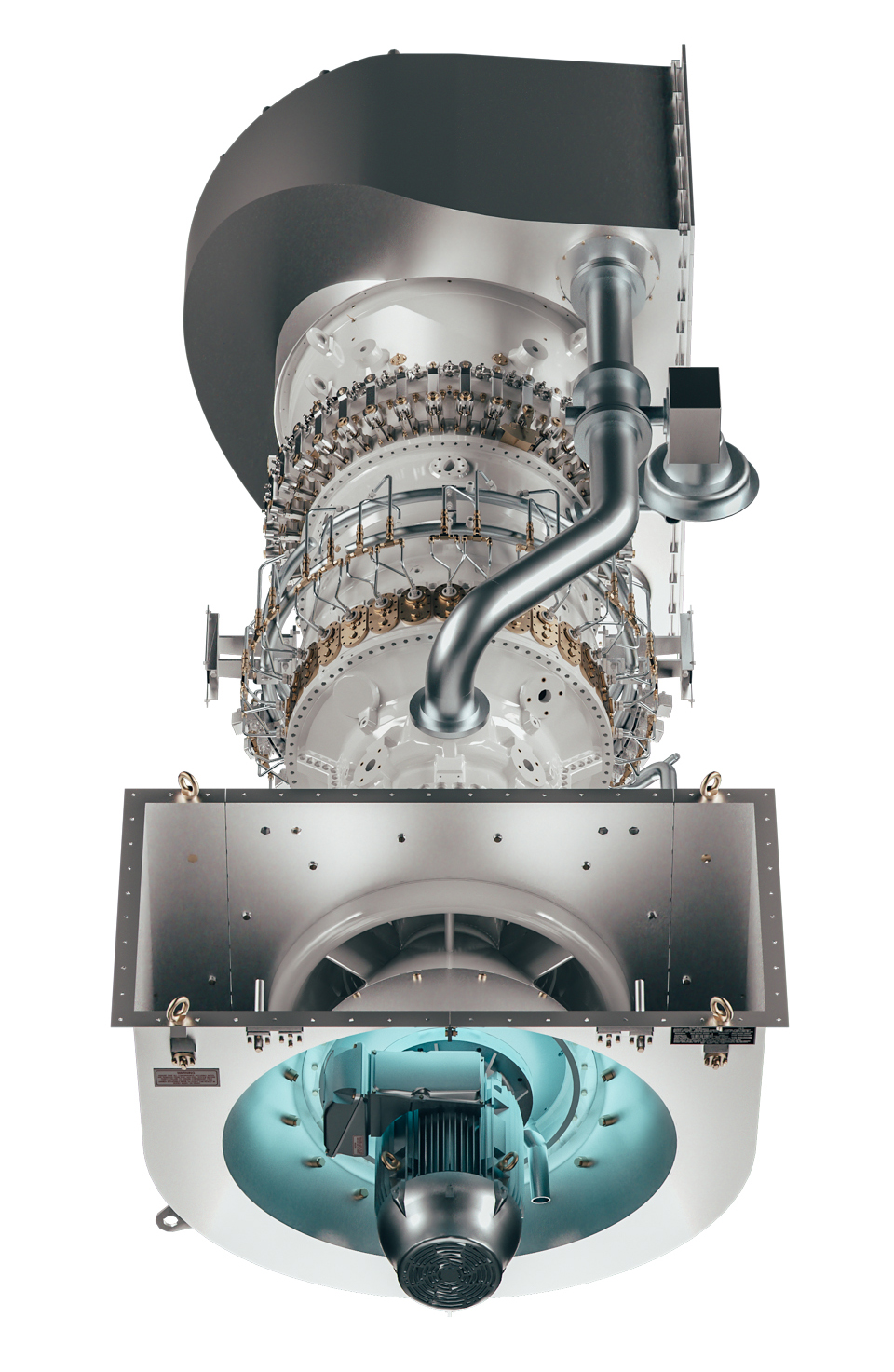

Axial compressor

Evolved from our Frame 5/2E design, the NovaL™T12 gas turbine has one stage added (from 11 to 12) for improved efficiency and a higher pressure ratio (from 17:1 to 19:1).

Extended maintenance plan

The NovaLT™12 gas turbine is designed for up to 35,000 hours mean time between maintenance (MTBM) without boroscope inspections, and targeting 24-hour engine swap. Real-time condition monitoring anticipates and helps prevent problems. If problems do occur, 24/7 product support service is available.

DLN automapping

Thanks to automapping, dry low emission (DLN) tuning is required and performed only during commissioning (which is 90% faster than for a traditional system), and every four years thereafter via remote connection with our RM&D Centers.

Hydrogen for energy transition

NovaLT™12 gas turbines can burn up to 30% hydrogen in DLN mode, and we’re moving toward 100% H2 capability.