The success of human activity in today’s world depends on continuous, reliable energy and power generation. Both are critical to maintaining the health and well-being of our global populations.

The demand for safe and reliable energy and power generation is expected to grow as people in countries across the world gain access to electricity. Regional energy requirements vary significantly depending on available resources to generate power, oversee local climate change regulations and manage greenhouse gas reduction.

Energy produced from fossil fuel sources such as coal, oil and gas, with gas being the greener option of the two, have proven to be staunchly reliable over decades. The relatively recent emergence of renewable energy sources such as wind, solar, hydroelectric and geothermal technical achievements offer comparatively green options that lead to cleaner air.

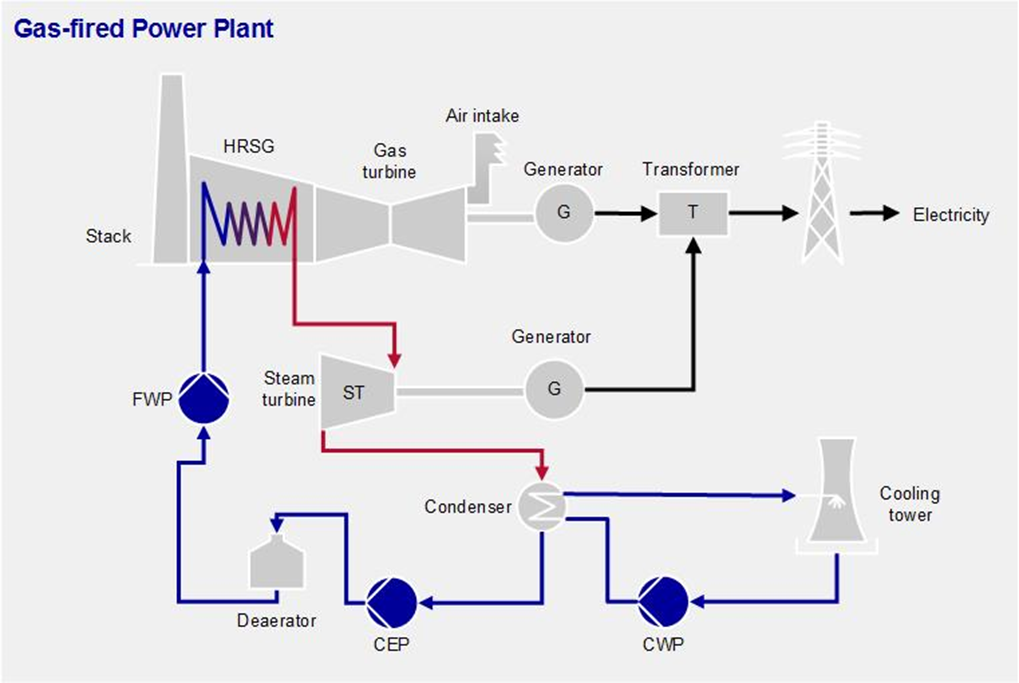

Power generation is connected to the electrical grid with multiple flow measurements required to monitor the energy produced while increasing overall plant efficiency, which implements the optimal solution for the best possible outcome while complying with environmental regulations.

The safe and efficient operation of a power plant requires tight control over an array of processes within the plant. Multiple flow technologies are used, with operators focused on high availability, high reliability and low operational expenditures generated by energy-efficient meters.

Critical gas and moisture measurement applications function primarily for power plant generators and the distribution side of a plant. One example of a process requires the cooling of a generator, which can be adversely affected by contamination from moisture or air from the coolant gas. Moisture can impede many processes in a power plant, which depend on a significant number of flow measurements from cooling water to air intake, boiler feed water to steam, demineralized water to natural gas, raw water to thermal fluids, and diesel oil to air stack.