On this webinar we show how Panametrics can support Semicon operators with the necessary measurement to achieve the highest purity goal

Research has proven that precise control of the oxygen content and reliable, contamination free flow measurement on ultrapure water, utility water and gas, as well as raw water and wastewater are required for chips and other electronics components manufactured in clean rooms down to class 1.

The process of water purification moves through a number of stages. While electromagnetic flowmeters can measure the amount and quality of raw water, once the water is demineralized and deionized, conductivity becomes too low. Chemical compounds on smaller lines with have lower flows. Although the precise details and quantities are not measurable, these compounds can include acetone, trichloroethylene and isopropyl alcohol, among others, most of which could cause safety hazards and therefore must be leak-free.

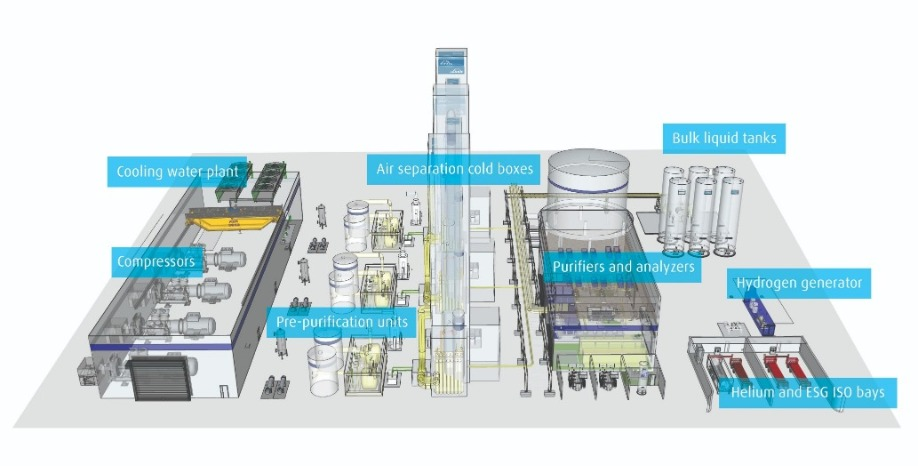

All gases feed industrial manufacturing plants with nitrogen, oxygen, argon, hydrogen, helium, carbon dioxide and air to enable manufacturing. Nitrogen, oxygen, argon, hydrogen and helium typically are typically employed as purge gases in the semiconductor fabrication process. These gases must be of the highest purity as even parts-per-billion (ppb) levels of contaminants, such as moisture and oxygen, can negatively impact process yield and product quality.

Panametrics clamp-on ultrasonics flow meters are installed in semiconductor plants for:

- Raw water, cooling water, chiller water, washing water, demineralized water, deionized water, wastewater from 15mm to 600mm (1/2” to 24”)

- Chemicals

- Utility gases: air, nitrogen, oxygen, argon, carbon dioxide from 15mm to 300mm (1/2” to 12”)

The main drivers towards this clamp-on technology are:

- Installation within minutes from outside the pipe

- No interruption of process

- No risk of contamination

- No drift over time

- Smart meters with embedded diagnostics to assess their ‘health’

- Improves energy efficiency as meters do not generate pressure drop

- Low CAPEX and OPEX

- Increases process availability with no downtime

- High reliability