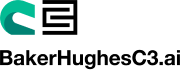

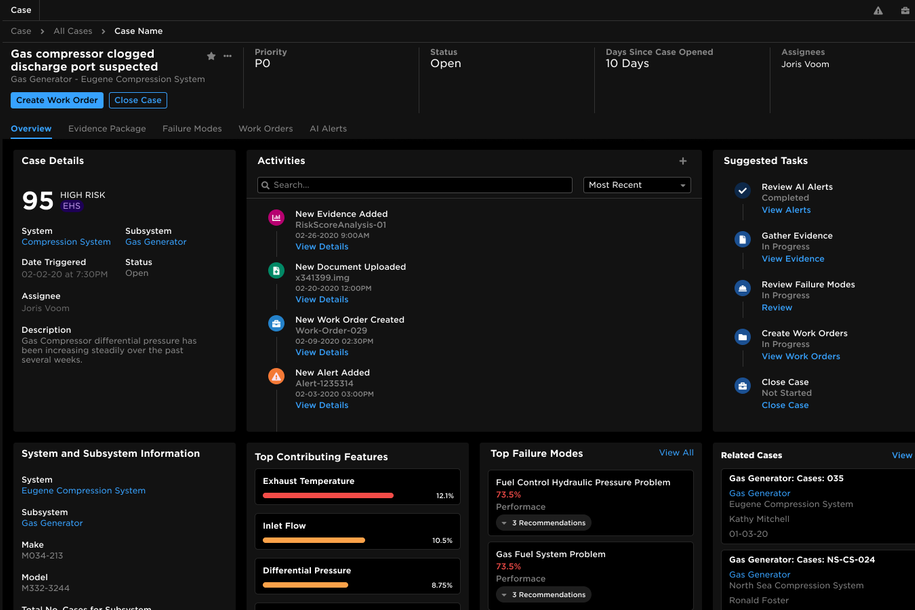

BHC3TM Reliability provides reliability engineers, maintenance managers, and executives with comprehensive monitoring across critical and non-critical assets, and enables proactive, AI-based predictive maintenance. BHC3 Reliability identifies anomalous behavior across systems and assets, provides prioritized alerts, recommends prescriptive actions, and enables collaboration through an integrated workflow. With BHC3 Reliability, enterprises can maximize uptime, reduce maintenance costs, and improve operational efficiency.

Reduce unplanned downtime, maximize asset availability, and increase safety

BHC3 Reliability demo video

Demonstrated Benefits

Next Generation AI-based Reliability

Issues

BHC3 Reliability Solution

Reactive, time-based, and expensive maintenance programs

AI-based asset risk predictions provide continuous visibility into overall asset health

Too many false alerts generated by rules-based systems

Early warnings for assets at risk are prioritized using machine learning and codified domain expertise

Difficult to track asset risks across thousands of systems and sensors

AI approach is scalable across complex assets, fleets, and systems

Operational knowledge siloed within an aging workforce

Automatic failure mode identification to prescribe mitigation steps and feedback loops augmented by AI

Disparate and unconnected reliability systems

Closed-loop workflow for all asset, maintenance, and operational systems

Key Capabilities

AI-based asset risk predictions

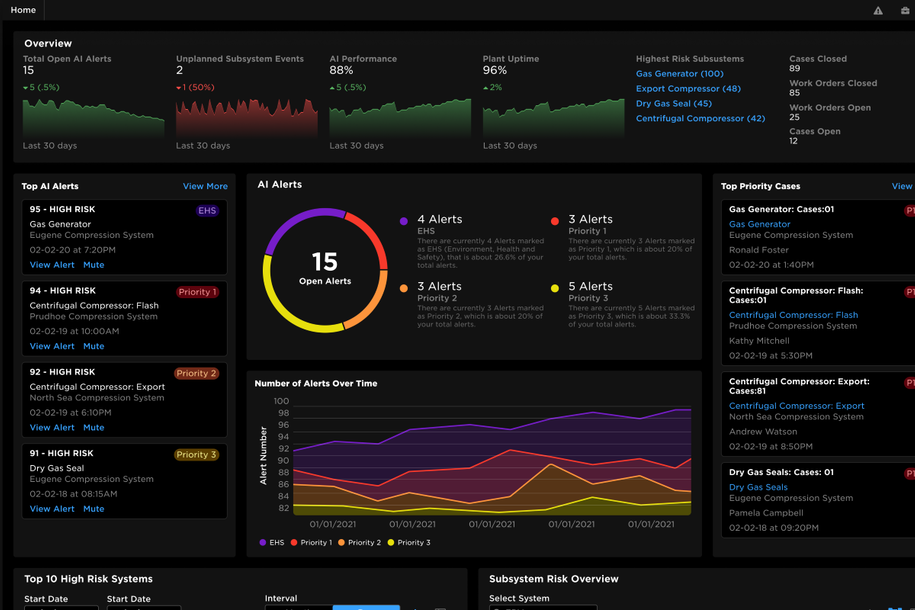

- Proactively assess real-time asset health, detect anomalies in asset operating conditions, and perform root cause analysis.

- Contextualize asset and system behavior with thousands of features.

- Prioritize maintenance activities for planned maintenance windows based on failure predictions.

Prioritized early warnings

- Identify anomalies using next-generation deep learning and machine learning algorithms.

- Prioritize issues and reduce the number of false alerts through AI/ML.

- Early warning of asset risks months ahead of time.

Scalable AI approach

- Scale application rapidly across any type of facility or asset fleet.

- Automated diagram parsing map sensors to assets and generate asset hierarchies.

- ML model management & configuration provide end-to-end management to end users.

Failure mode identification and mitigation

- Leverage AI/ML interpretability to explain factors contributing to asset risks.

- Identify failure modes using codified domain expertise with cross-industry diagnostic libraries.

- Prescribe remediation actions to guide engineers in rapid risk resolution.

Closed-loop workflows

- Streamline workflows across software tools by launching work orders in existing CMMS systems

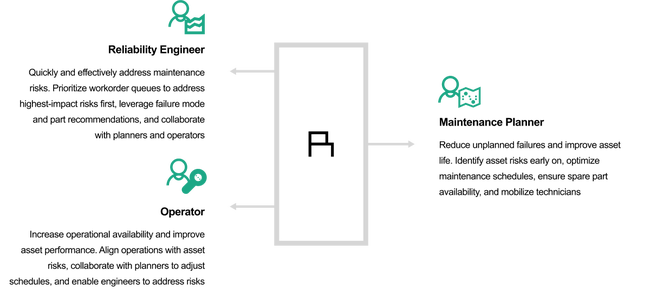

- Collaborate across the organization with operator, engineer, and manager views

- Tune the machine learning models to accommodate operations complexity

Benefits for BHC3 Reliability Users