BHC3TM Process Optimization applies advanced analytics techniques on top of operational data to improve production yield and process efficiency. BHC3 Process Optimization identifies process anomalies across systems, provides prioritized alerts and process KPIs, enables root cause analysis, and recommends optimization actions. Process and production engineers can use BHC3 Process Optimization to maximize production levels and optimize energy efficiency.

Increase Product Yield, Improve Quality, and Boost Efficiency

BHC3 Process Optimization applies machine learning techniques to continuously monitor and predict product yield, identify quality problems, and optimize process energy utilization and process control parameters.

BHC3 Process Optimization Demo Video

Demonstrated Benefits

Next Generation AI-based Process Optimization

Issues

BHC3 Process Optimization Solution

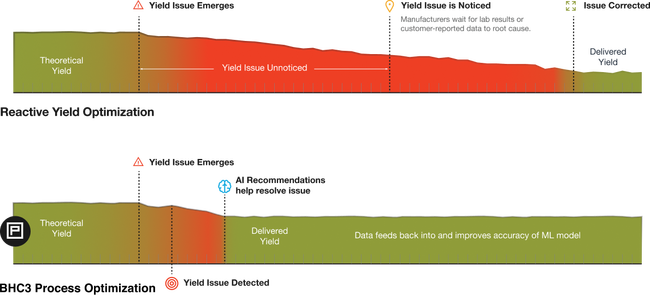

Product yield is variable over time

Product yields and quality forecasted through advanced AI techniques to reduce waste and maximize production

Quality issues emerge without sufficient warning

AI prediction enables operators to act before a product issue emerges

Lab testing and related data are not integrated with operational data

Unified date from process simulators, operational systems, ERP systems, and asset management systems provide a holistic view of production process

Existing solutions do not handle all process types

Support for discrete, batch, semi-batch and continuous production processes

Unpredictable impact of reactive solutions on quality issues

Integration of process simulators and optimization frameworks to evaluate what-if scenarios

Inefficient collaboration and triage

Enable operators to focus on high-priority issues and leverage AI-based prescriptive insights to support intervention

Key Capabilities

Optimize production process in near real-time

- Gain near real-time visibility into production process.

- Continuously monitor yield and process through high-level KPIs and rich visuals.

- Quickly identify risks and focus operators on the most urgent issues.

Predict production quality and yield

- Leverage advanced machine learning algorithms that predict end-product yield and quality in advance.

- Optimize setpoint handles with recommendations based on actual plant operating conditions.

- Maximize yield while minimizing energy and supplied materials input.

Use of all relevant lab, enterprise, and operational data

- Unify data from process simulators, operational systems, ERP systems, and asset management systems to create a holistic view of production process.

- Time-align lab testing data with the operating conditions using native time-series support for all data.

Support all types of production processes

- Enable holistic monitoring for discrete, batch, semi-batch, or continuous production processes.

- Applicable for upstream, midstream, and downstream operations.

Comprehensive scenario analyses and simulations

- Leverage integration with process simulators and best-in-class optimization frameworks

- Analyze and benchmark what-if scenarios to assess the impact of operational changes on throughput and cost

- Assess simulated effect on quality, yield, and material consumption

Enterprise-wide collaboration on production operations

- Align engineering, operations, maintenance, quality, and testing teams with configured dashboards

- Reduce time and effort spent on data aggregation and improve accuracy of optimization analyses

- Use bi-directional integration with existing systems of record

Benefits for BHC3 Process Optimization Users