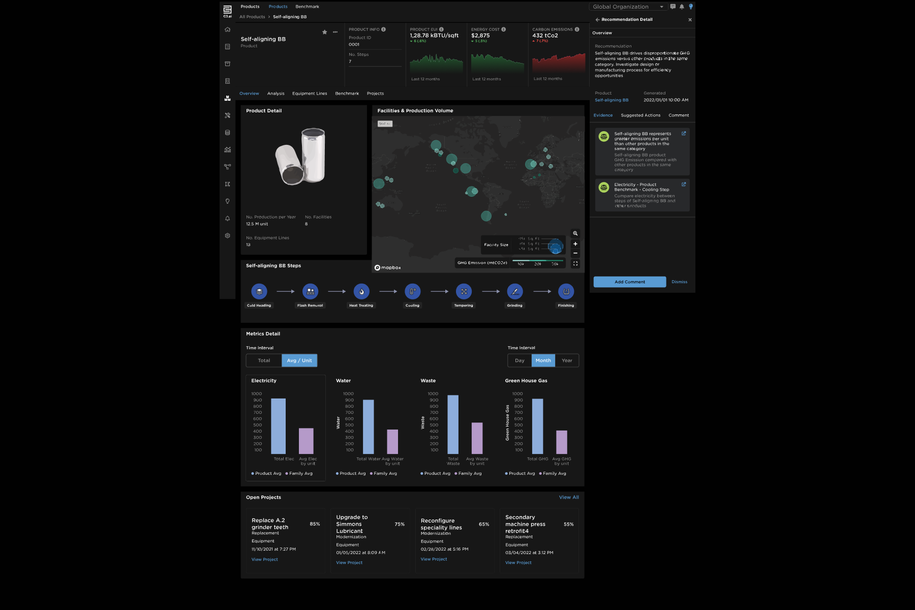

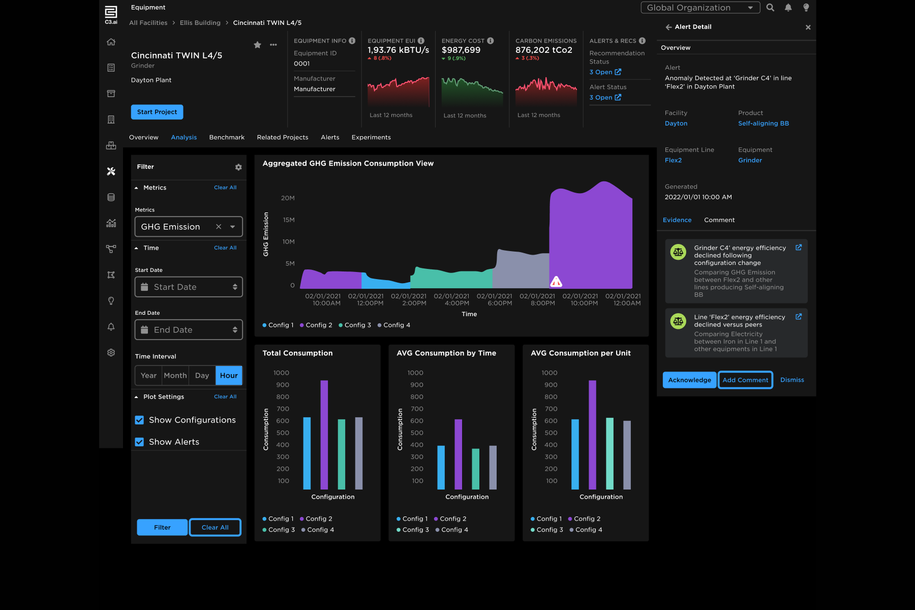

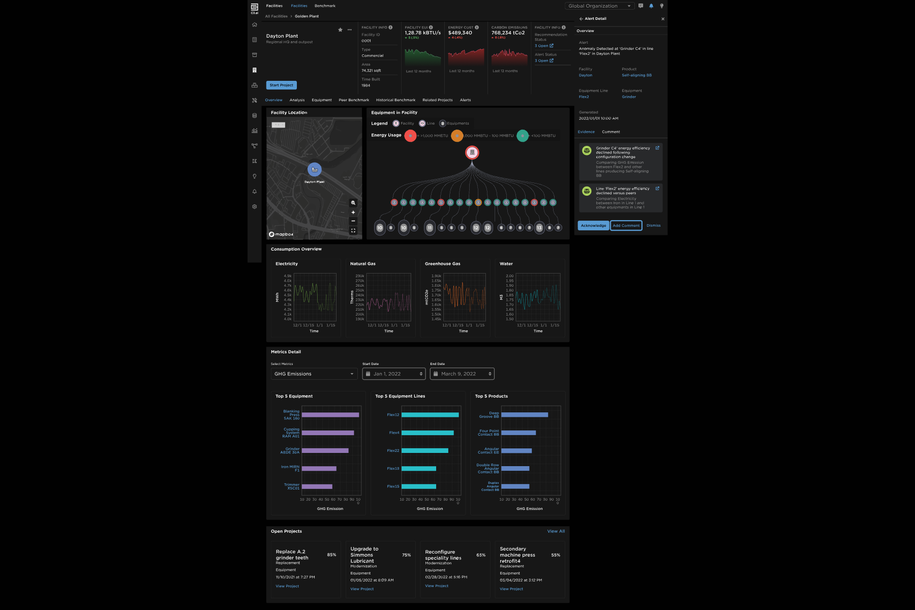

BHC3 Sustainability helps sustainability, plant, and energy managers achieve targets for energy cost, GHG emissions, water consumption, and waste reduction. The application models energy efficiency and emissions at every level of the industrial process from the individual asset to the entire plant carbon footprint. Advanced AI models identify opportunities for energy efficiency, prioritize emission reduction strategies, alert operators to efficiency anomalies, and verify progress against sustainability goals.

Advanced analysis to maximize impact

Demonstrated Benefits

AI-Powered Sustainable Production Operations

Pain Point

BHC3 Sustainability Solution

Lack of comprehensive visibility into equipment, line, and process-level sustainability metrics

Sustainability-focused digital twins of production facilities provide view of fuel efficiency, emissions, water, and waste within and across plants, including leak detection and flaring tracking

Limited collaboration between sustainability and operations teams to identify project opportunities

AI-based alerts and recommendations identify specific operational opportunities with estimated sustainability impact

Inability to track product carbon footprints and leverage sustainability investments to competitively differentiate

Industry-specific data models and out-of-the-box emission factor libraries enable advanced product carbon footprint analysis

Time-consuming manual calculation of project savings

Automated AI/ML project savings measurement and verification track sustainability ROI at the equipment and facility levels

Difficult to track and report progress against sustainability goals

Continuous monitoring of facility and enterprise sustainability goals aligned to major ESG reporting requirements

Existing systems are rigid, closed, and not scalable

Flexible, secure, and open platform offers robust integrations and full interoperability with all enterprise and extraprise systems such as historian systems, flare stack sensors, PEMS, CEMS

Key Capabilities

Sustainability-focused digital twins of energy facilities

- Leverage pre-built data connectors and industry-specific data model extensions to gain visibility into equipment, line, and process-level emissions, waste, and water

- Baseline and benchmark within and across plants to identify high-value opportunities for energy efficiency

AI alerts and sustainability recommendations

- AI models track and learn relationships between equipment and line configurations and environmental impact (GHG emissions, water, waste, and energy)

- SMS and email notifications deliver actionable insight for efficiency opportunities and emerging sustainability risks

Near real-time product carbon footprint analysis

- Model production processes and utilize sensor data and pre-configured emission factors to calculate embedded carbon at the product level

- Share with suppliers, customers, and employees the product-level environmental footprint and results of sustainability initiatives

Automated project savings measurement and verification

- Measure and verify cost and carbon savings of projects using machine learning baseline models

- Automatically monitor ROI over time and notify users of changes in project performance

Robust goal-tracking and reporting

- Track projects and initiatives against sustainability goals to ensure continuous progress

- Report on accomplishments and gap-to-targets both internally and externally

Flexible, secure, and open platform

- Robust pre-built integrations with plant historians, IoT sensors, meters, ERP, project management, and utility billing systems

- Scalable across a global footprint of plants and terabytes of high frequency data

Benefits for Energy Professionals