Highlights

Highlights

Benefits

- Set and run in one trip on either electric wireline or coiled tubing

- Retrieve from the wellbore for multizone applications

Other Benefits

- Run through the existing completion and set in up to 7 5/8-in. casing

Overview

Ensure effective thru-tubing interventions with the Delta Exit System™ from Baker Hughes. A proven thru-tubing casing exit system, the Delta Exit System lets you mill a window in your casing in a restricted wellbore environment using coiled tubing-deployed mills and motors.

Get unsurpassed milling flexibility and efficiency

Run and set the Delta Exit System in a live well environment, without having to remove the completion equipment—thus eliminating the requirement for a workover rig and negating the need for kill weight fluids.

And since the Delta Exit System is designed to be run and set on either electric wireline or coiled tubing, it is ideally suited for restricted bore access and allows the window to be milled below the completion.

The whipstock anchor is firmly set for either high- or low-side exits with a Size 10 Baker Hughes E-4™ wireline pressure setting assembly (product family nos. H43702 and H43720) or a Size 10 Baker Hughes J™ hydraulic setting tool (product family no. H41371).

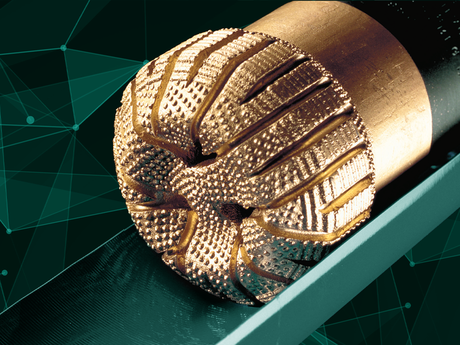

The system accommodates a wide range of mill styles for efficient window cutting in a wide variety of your formation and casing conditions.