Condition Monitoring for the Pulp and Paper Industry

Your Business has Challenges.

In an increasingly competitive business environment, there are many things you can't control, like the cost of lumber, process chemicals, and energy just to name a few. What you can control to a large extent is making your production run safely and reliably through a plant-wide condition monitoring program from Bently Nevada. Bently Nevada has been a trusted partner to industry for over 60 years. We understand your processes and mechanical assets. Let us help you create a condition monitoring program that fits your goals and budget.

When implementing a new reliability program, there are three areas you must address:

Processes: For over 60 years, Bently Nevada has been helping customers assess their goals, identify reliability gaps in current operations, and then implementing the appropriate corrective actions and strategies to keep operations running smoothly.

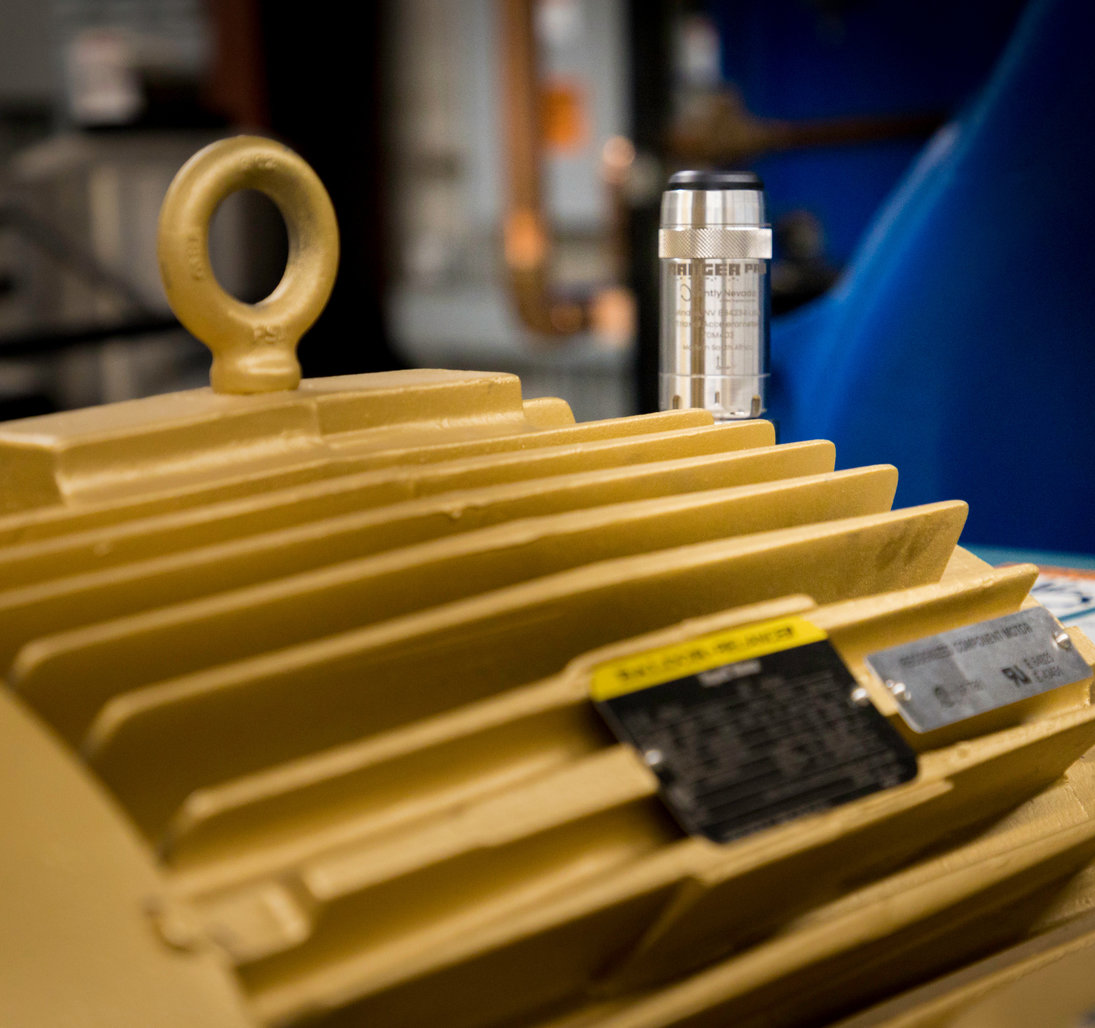

Tools: Our Bently Nevada product line is world-renowned for unsurpassed quality in machinery condition monitoring. Everything needed to address the assets in water and wastewater treatment plants is available, from sensors to continuous monitoring systems to wireless sensor systems to portable data collectors and analyzers. And, it’s all brought together in a unified platform for asset condition monitoring and diagnostics—Bently Nevada’s System 1 software. We also assist customers in integrating and using their already installed tools, such as computerized maintenance management systems (CMMS) and reliability software.

People: Reliability is about more than just technologies and processes. Armed with even the most sophisticated tools and effective strategies, companies can fail to reach their reliability goals unless they are able to successfully change the way they work. Reliability is a company-wide effort that touches operations, maintenance, planning and scheduling, purchasing, management, and engineering. Bently Nevada is able to help customers change the way they work by addressing the organizational culture issuesthat keep companies mired in ineffective processes, helping them transform their businesses and balance sheets.

Helping Pulp and Paper Mills Succeed

Maintenance: the hidden profit generator in pulp and paper manufacturing

Dynamic, proactive condition monitoring approaches increase uptime, optimize productivity, and maximize profits

Pulp and paper operations must leverage maintenance strategically, and as a continuous improvement process to better optimize manufacturing and improve profits. To do this, leading manufacturers have but one choice: to adopt intelligent, condition monitoring planning capabilities that perpetually—and proactively—optimize operations. This is the next vital step in pulp and paper’s evolution—and survival. This paper is an excellent way to take the next step.