Bently Nevada is one of the Condition Monitoring firms that can rightly claim they invented the whole concept of Asset Management in the first place.

- Control Magazine

The success of any industrial operation relies heavily on the proper care and management of the machinery powering the work. Unplanned outages or inefficient maintenance routines can reduce productivity and erode profits.

At Bently Nevada, we began the process of revolutionizing how operations across all industries monitor machinery asset condition over 60 years ago, and we've continued to pioneer the process ever since. Bently Nevada provides an "edge to cloud" solution for Asset Health Monitoring that spans from sensing and protection of edge and on-premise assets, through the cloud, with data and analytics solutions to provide a real-time, complete picture of asset health.

Why Asset Health Management

Integrated connection

Enhanced connection between Asset Health Management and Work Execution allows maintenance and repair work to be executed as efficiently as possible

Improved data clarity and context

Our decades of industry expertise allows us to provide improved asset data context and clarity to avoid prematurely running to failure without context or pre-warning

Enhanced prioritization and resource allocation

Better prioritize response and resource allocation by more accurately determining the scope or impact of degradation

Making the Case for Plant-wide Condition Monitoring

A comprehensive plantwide combination of continuous online, scanning, portable and wireless capabilities can provide condition monitoring for every asset class within almost every industry setting. Bringing both protection and condition monitoring into a single system with one HMI (along with hosting and implementation) has truly brought condition monitoring into a new age.

Comprehensive coverage with end-to-end results

Edge-to-enterprise condition monitoring coverage

Asset Health Management (AHM)

In 2000, the vision of “one system” was born with System 1. Since then, Bently Nevada has worked to continuously improve the connectivity, analytic, and visualization capabilities of the System 1 platform. Today, System 1 offers a premier plant-wide condition monitoring experience for industrial operators that extends from edge to enterprise, allowing greater accessibility to users with a strict backbone of cyber security features.

Orbit 60 Real-time Monitoring

The next generation of machinery protection and condition monitoring, designed to be the most advanced system for all your critical machinery and balance of plant assets.

3500 TDI Real-time Monitoring

Since 1995, the 3500 flagship monitoring system has become the world-leader for customers across all industries requiring the best protection system for their critical machinery.

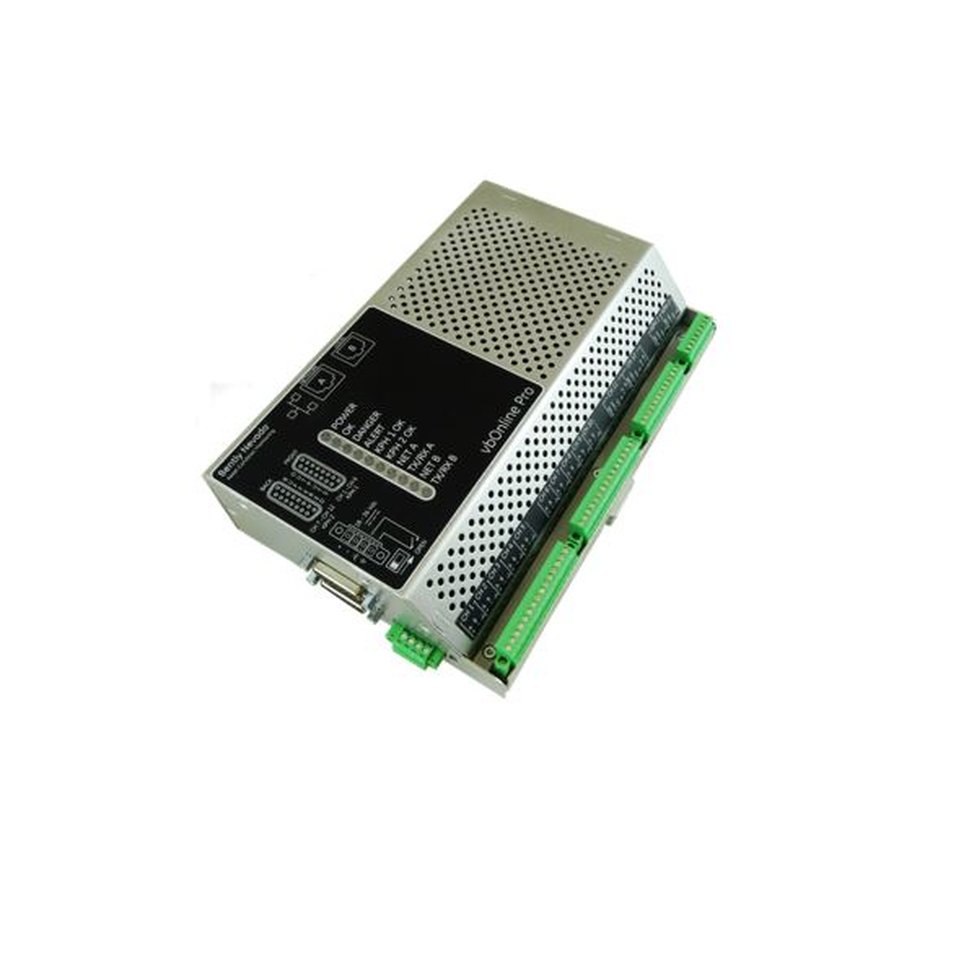

vbOnline Pro Online Monitoring

A flexible, scalable system that provides automated, user-scheduled monitoring of an asset’s mechanical health.

Trendmaster Online Monitoring

An innovative, cost-effective online vibration monitoring system that links hundreds of permanently mounted transducers and measurement points to a single-cable sensor network.

Ranger Pro Wireless Monitoring

More than just a vibration sensor, the Ranger Pro allows for 24/7 monitoring of velocity, acceleration, and temperature plus time-base waveforms, spectra, and PeakDemod spectrum on important machine assets.

Machine Health Powered by Augury

Machine Health Powered by Augury is a complete, end-to-end industrial machine solution which includes wireless IoT hardware, software, advanced diagnostics, and services to deliver benefits from the plant floor to the executive office.

How does Asset Condition Monitoring help?

Saves Time & Money...

Compared to time-based maintenance, condition-based maintenance saves time and money by only performing maintenance checks when they are necessary

Asset Insights...

Provides users insight to understand when and why an asset is likely to break down, allowing them to prepare for and potentially avoid machine breakdowns

More Uptime...

Reduces unplanned outages or inefficient maintenance routines, which leads to increased productivity and profits

How Asset Condition Monitoring helps?

Saves time & money on maintenance...

Compared to time-based maintenance, condition-based maintenance saves time and money by only performing maintenance checks when they are necessary

Greater asset insights...

Provides users insight to understand when and why an asset is likely to break down, allowing them to prepare for and potentially avoid machine breakdowns

More uptime...

Reduces unplanned outages or inefficient maintenance routines, which leads to increased productivity and profits

SCOUT Portable Vibration Analyzer

Brings industry-leading condition monitoring expertise to the world of plantwide machinery portable data collection with Bluetooth streaming data directly from the data collector to a durable hand-held smartphone.

ADRE Portable Diagnostic Device

A rugged, multi-channel machine DAQ that handles a broad range of critical machinery data acquisition tasks, enabling users to spend minimal time reducing machinery data and more time interpreting it in real-time with our System 1 ACM software.