Remote Monitoring & Diagnostics Service team’s quick response saves Wind farm from severe losses

Overview

Alert engineers identified a potentially serious problem with the gearbox of a customer’s wind turbine, advising the customer to inspect the gears without delay.

Challenge

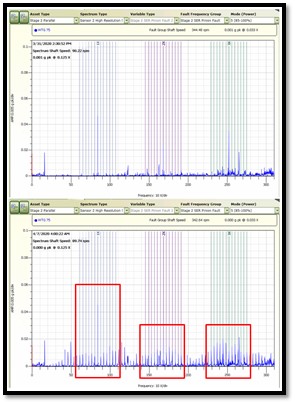

Such is the essential work of our Bently Nevada Remote Monitoring & Diagnostics engineers. “In this situation, the inspection revealed a broken tooth on the intermediate speed gear and excessive pitting on the low speed gear,” said RM&D engineer Garrett Olson. “If left unresolved, this event could have caused a very expensive and catastrophic failure.”

Conclusion & Solution

The RM&D Center’s timely notification enabled the customer to safely schedule a replacement of the gear assemblies. Early detection of the problem by the RM&D allowed the customer to promptly perform repairs within the nacelle, the enclosure at the top of the wind turbine tower, saving $200K USD+ according to the customer. The alternative would have required the use of a crane along with extensive heavy-lift equipment and personnel to install a complete gearbox replacement at the top of the tower.

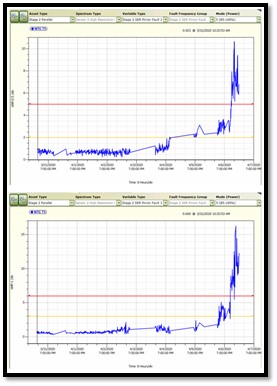

BN engineers in the RM&D Center monitor the software and hardware of the Adapt.Wind/60M100 Condition Monitoring System (CMS), providing on-line supervision of wind turbine machine trains with sophisticated signal processing algorithms and machine operating states. When a turbine defect exists, engineers alert the customer to take action thereby preventing the failure of a turbine asset.

Bently Nevada's Condition Monitoring Solution can save turbine owners hundreds of thousands to millions of dollars per year in lost revenue, depending on the size of the wind farm. Turbine owners can expect to see cost savings from several sources, including reduced crane costs as well as early detection and minimized damage.

Furthermore, turbine owners will see a significant reduction in unnecessary turbine outages and production losses over time.

“Remote monitoring works,” said RM&D Center Operations Leader Steven Ciesla. “We provide value to our customers by immediately detecting problems and delivering actionable recommendations to help them investigate and resolve their machinery problems systematically, thoroughly and without delay.”

Inspection Findings

The unit was halted and the customer performed a borescope inspection.

The gearbox showed a broken tooth on the Intermediate Speed gear along with excessive pitting on the Low Speed gear. The customer resolved to replace the IMS and HSS assemblies up-tower.

Copyright 2019 Baker Hughes Company. All rights reserved. 베이커휴즈는 이 정보를 일반적인 정보 목적으로 ‘있는 그대로’ 제공합니다. 베이커휴즈는 정보의 정확성 또는 완전성에 대해 어떠한 진술도 하지 않으며, 상업성 및 특정 목적 또는 사용에 대한 적합성을 포함하여 법률이 허용하는 한도 내에서 구체적, 묵시적 또는 구두로 어떠한 종류의 보증도 하지 않습니다. 이에 의하여 베이커휴즈는 청구가 계약, 불법 행위 또는 기타 방식으로 주장되는지 여부에 관계없이 직접적, 간접적, 결과적 또는 특별 손해, 이익 손실 청구 또는 정보 사용으로 인해 발생하는 제삼자 청구에 대해 일체의 책임을 지지 않습니다. 베이커휴즈는 통지 또는 의무 없이 언제든지 본 문서에 명시된 사양 및 기능을 변경하거나 설명된 제품의 제공을 중단할 수 있는 권리를 보유합니다. 최신 정보는 베이커휴즈 담당자에게 문의하십시오. 베이커휴즈 로고, 벤틀리 네바다 로고, System 1은 Baker Hughes Company의 상표입니다.