Highlights

Highlights

Benefits

- Greater understanding of pipe temperature profile

- Indicated flow assurance problems

- Early indicator of various integrity issues

Features

- Continuous temperature measurement manufactured into flexibles

- Measurements with +/- 0.1°C accuracy

- Cloud-based software streaming data 24/7

Applications

- Continuous monitoring system embedded into the flexibles during manufacturing

- Connection to the control unit via fibre optic cabling

- Data management and visualisation through the Baker Hughes Dashboard

Overview

Flow Assurance and Outer Sheath Integrity

DTS is a fibre optic temperature sensing technology that provides continuous and precise temperature measurement along flexible pipes using a cloud-based software where real time flow temperatures can be streamed 24/7. The technology attains +/- 0.1°C accuracy and provides valuable data for flow assurance, late life managing, identifying blockages, integrity management and axial movement monitoring.

Ways DTS Support Field Performance

- DTS allows the real time temperature profile within a production flow to be continuously monitored so differences between flow assurance modelling can be quickly identified.

- DTS temperature measurements can record the cool down time of the line during shut-in events which gives a greater understanding of transient system performance for input into flow assurance simulations.

- The technology can provide the full temperature profile from seabed to surface which is valuable in identifying issues such as blockages.

- Continuous temperature monitoring is especially valuable in late field life as production rates vary. The data accumulated allows for intelligent field management decisions to be taken.

- Temperature monitoring along a flexible pipe can be an early real time indicator of various integrity issues as burial of a pipe results in heat entrapment or upheaval buckling causes cold spots.

- DTS can be used to monitor axial movement of ancillary equipment such as buoyancy modules in real time.

Engineering Principle

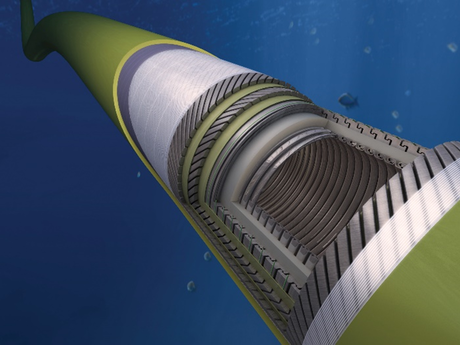

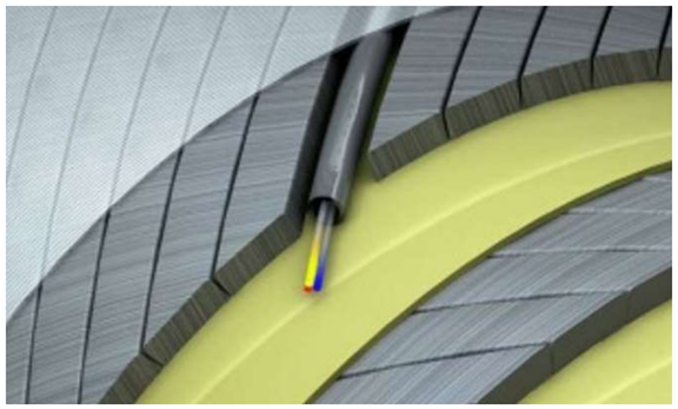

A fibre optic cable, embedded in a small-bore stainless-steel tube is wrapped between tensile armours during pipe manufacturing. The fibre optic cable is terminated in the topside end fitting within an optical connector. A short pulse of laser light is directed into the fibre from the topside optical connector, the pulse creates backscatter at each location along the fibre. DTS measures the Raman backscatter received at the topside optical connector and from the characteristics of the back scatter received at different times, it is possible to determine the temperature at each location.

Implementation

DTS is offered as a continuous monitoring system which can optionally be incorporated into Baker Hughes flexibles during the manufacturing phase. Offshore the optical connector fitted to the topside end fitting will be connected to a control unit via fibre optic cabling. The control unit communicates via ethernet with the Baker Hughes Dashboard data management system.