Case Studies

1/8

Highlights

Benefits

- Improved reliability, availability, and performance

- Faster troubleshooting, maintenance cost savings, higher operating efficiency

Features

- Advanced digital technologies and proven engineering expertise

- Continuous monitoring, diagnostics, and support; expert root-cause analysis and remediation

- Performance optimization and emissions management

Applications

- Energy applications including oil and gas, thermal, geothermal, co-generation, solar, hydrogen, and CCUS

- Industrial power generation, mechanical drive, heating and cooling

Overview

Remote monitoring and diagnostics

- Online monitoring of turbomachinery assets health, performances, and emissions

- Data collection and processing by proprietary analytics leveraging 25+ years of experience and more than 1,700 assets monitored worldwide

- 24/7/365 experienced Baker Hughes experts to support anywhere in the world

- Early warnings, technical assessments, recommendations, and decision‑support in case of unexpected events, failures, or trips

Image

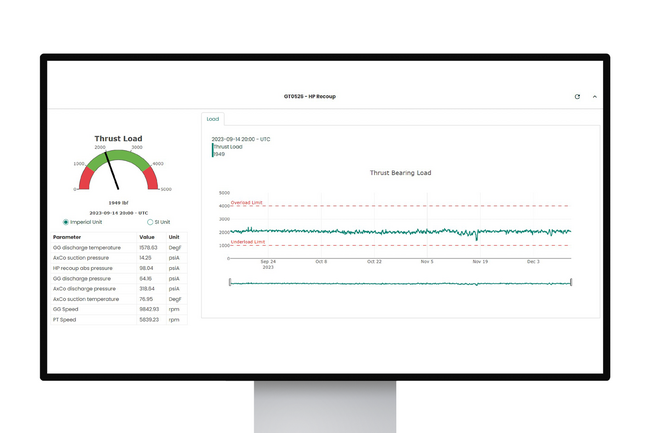

Thrust bearing load

- This digital solution identifies potential overloading/underloading stress by continuously monitoring thrust‑bearing operational loading for aeroderivative gas turbines

- Corrective actions are suggested to avoid running in off-design conditions and optimize the entire engine lifecycle through orifice tuning

- Combine with Maintenance Flexibility capabilities to safely extend maintenance intervals through asset degradation risk monitoring

Image

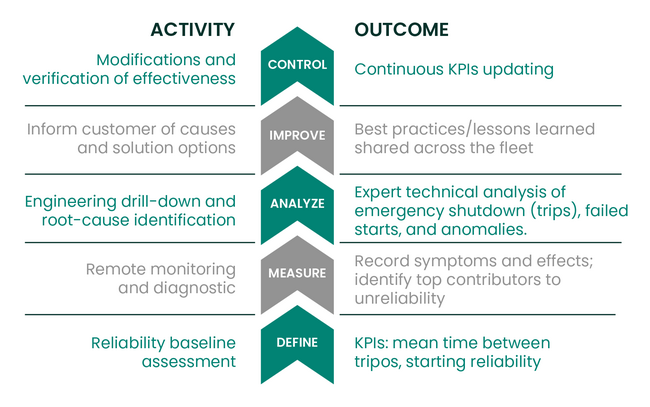

Trip-reduction program

- Our trip-reduction program (TRP) increases turbomachinery reliability and minimizes production losses by identifying and eliminating the causes of recurring trips—either from issues with the unit itself or from wider plant operations

- Expert technical analysis of emergency shutdown and failed startup delivers suggested corrective actions to be implemented across fleet

Image

Performance indicator and logistics optimizing tool

- Monitor and analyze equipment performance and major downtime contributors in your compression and power generation trains. Identify major downtime contributors in your fleet

- Record planned and unplanned maintenance events along with relevant systems information and operating indicators (reliability, availability, MTBM, MTBF, MTTR, etc.), calculated based ISO standards

- Fleet analysis based on specific segmentation criteria such as technology, equipment type, industry, or service class

Image

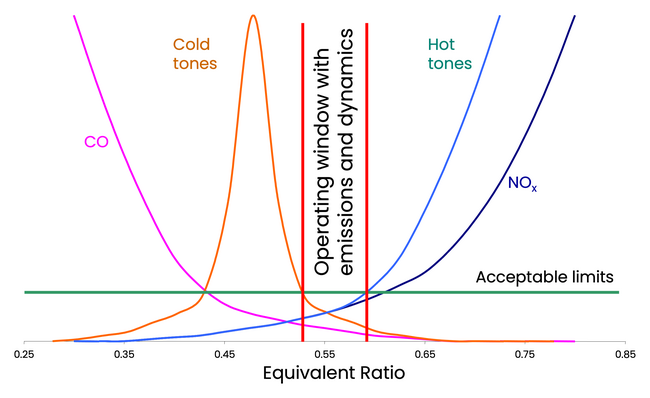

Remote combustion tuning

- Baker Hughes expert engineers perform combustion tuning remotely, increasing turbomachinery availability and ensuring quality and timely response, with no need to travel to site

- You can always count on the best support, thanks to remote iCenter™ expertise, to enhance monitoring and troubleshooting with valuable insights and suggestions

Image

Control system advanced service

Remote service for advanced support and troubleshooting on machine control systems, leveraging on Service Engineering control specialist.

Main features:

Proactive

- Control systems diagnostic alarm monitoring 24/7

- Periodic assessment of control system health (quarterly)

On demand

- Remote connection to HMI

- Remote troubleshooting with live data

- Remote support: implement settings fix

Image