Case Studies

Highlights

Benefits

- Higher efficiency with lower fuel consumption and CO₂ emissions

- Fewer trips, higher reliability and availability

- More accurate production planning and optimized operating costs

Features

- Digital gas turbine and compressor control

- Optimization of CO₂ emissions and fuel consumption

- Power monitoring with proprietary Baker Hughes models

Applications

- Energy applications including oil and gas, thermal, geothermal, co-generation, solar, hydrogen, and CCUS

- Industrial power generation, mechanical drive, heating and cooling

Overview

Predictive emissions monitoring system (PEMS)

Continuous monitoring of your emissions: PEMS predicts gas turbine emission levels (NOx, CO, O2)

Easy to configure: Mapping of the machine at startup and recalibrated once a year. No need to install sensors

Tested accuracy: Results comparable to a conventional sensor-based solution (CEMS). Solution developed in line with international regulation standards

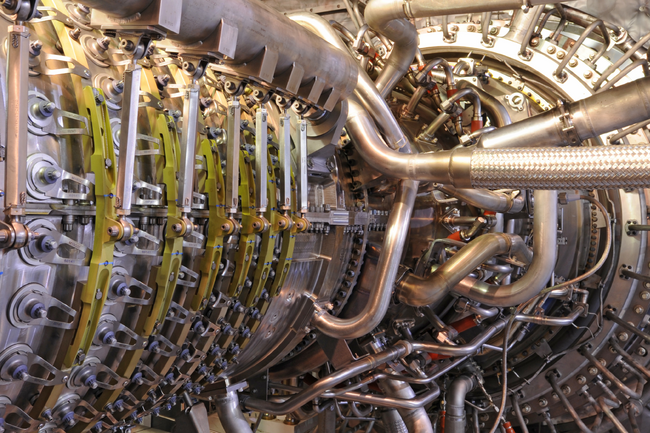

Efficiency booster

- This edge solution increases fuel efficiency for aeroderivative gas turbines

- Software logic stages-down combustion modes closing the bleed valve

- Increases efficiency while reducing fuel consumption and CO2 emission

- Delivered power is not affected

Carbon optimizer

- A suite of edge and cloud solutions to reduce CO2 emissions while optimizing fuel consumption based on a combination of digital intelligence from advanced algorithms and engineering expertise

- A dedicated web application shows real-time expected fuel and CO2 estimates and advisories for operators to adjust control variables and power set points

Automapping

- This edge solution guarantees CO and NOx emission levels by real‑time adjustment of flame temperature over each dry low emission (DLE) fuel manifold

- Acoustic and blow-out avoidance is based on internal predictive models and acoustics readings

- It increases reliability and availability by reducing risk of combustion trips

- Executed locally with no additional control hardware needed

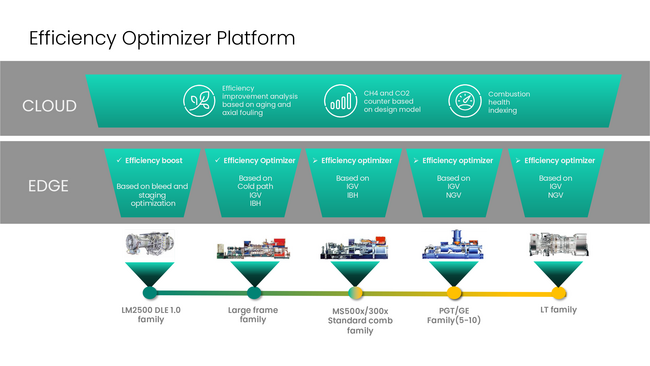

Efficiency optimizer

- Increases fuel efficiency by regulating inlet guide vane during gas turbine operation at partial load

- Delivered power is not affected

Operating point optimization

Centrifugal compressor thermodynamic performance assessment and compressor operative profile over time provides the following insights:

- Compressor actual performance

- Compressor actual vs. baseline performance with deviation of actual operating condition with respect to design condition

- Compressor operability analysis: load analysis and comparison between parallel/series trains

Operability recommendation aimed to reduce absorbed power or increase plant throughput or pressure ratio, depending on performance assessment and plant process constraints.

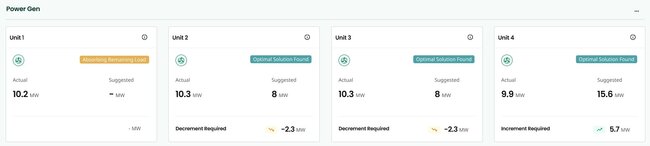

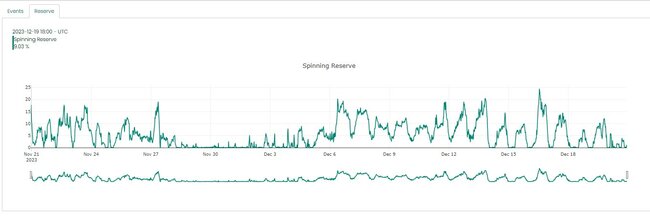

Spinning reserve

- Gas turbine power output monitoring based on proprietary Baker Hughes models of the gas turbine with estimation of maximum available shaft as a result of ambient condition and engine performance, estimated at power turbine design speed

- Accurate visualization of turbine output power enables more accurate production planning

Axial compressor water wash optimization

- Digital solution to evaluate optimal scheduling for axial compressor washing to enhance production while maintaining high efficiency and minimizing downtime or partial-load operation of the unit

- Accurate performance monitoring and estimation of the engine degradation associated with additional power compared to water‑wash schedule and possible cost savings in case of wash postponement (tailored on an engine‑by‑engine basis)

- Possible scenarios with different water-wash strategies/costs upon request (“what-if” scenarios) to support customer decisions

Filter change advisory

This solution provides online monitoring of the performance and degradation of the gas turbine’s inlet air filter

Suggests optimal replacement date based on the best compromise between production losses and maintenance costs:

- Turbine parameters: inlet DP spell out, environmental and operating conditions

- Financials: filter cost, fuel cost, ML loss cost, outage cost

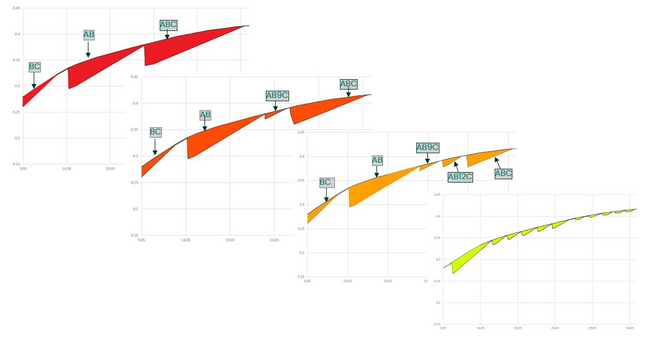

Partial-power efficiency

- Edge software solution that optimizes burner modes to minimize bleed airflow with consequent part-load efficiency increase

- Software tuning: optional steady-state partial burner modes to achieve increments in part-load engine efficiency while bleed airflow is minimized

- Up to 7% part-load efficiency Increase while maintaining current emissions guarantees, delivered power not affected