Highlights

Benefits

- Protect control systems from typical cyber risks

- Automate and remotely execute operation and maintenance tasks

- Reduce or eliminate on-site personnel

Features

- Hardware and software upgrades and predictive services for automation and remote execution

- Surveillance systems and remote control

Applications

- Energy applications including oil and gas, thermal, geothermal, co-generation, solar, hydrogen, and CCUS

- Industrial power generation, mechanical drive, heating and cooling

Overview

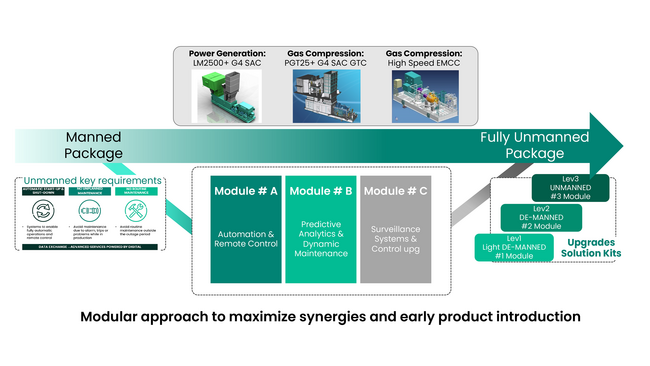

De-manned operation

De-manning is achieved introducing several solutions in the standard “manned” package for power generation and compression.

The overall solution is released in 3 modules:

- Hardware upgrades for automation and remotization

- Maintenance optimizer

- Surveillance systems and remote-controlled operation: software upgrades on controls systems and connectivity, surveillance system, and online oil monitoring to enable reliable remote operation

The implementation of all modules results in full un-manning, but they can be also applied partially to reduce number of technicians at site (“de‑manning”).

Controls cyber security

This service is designed to improve and maintain the cyber resilience on your network of Mark Ve/Vie control systems for rotating machines. It protects the control systems from typical cyber risks and remediates vulnerabilities.

Key features:

- Implementation of operating-system patches • Anti-virus signature update

- Installation of software security service pack for HMI and engineering workstations

- Installation and verification are performed remotely by Baker Hughes personnel

Hardware upgrades for automation and remotization

- Hardware upgrades kit for de-manning operation. Enable remote operation during unit start-up and shutdown phase or allow the reduction of field operators for tasks on demand

- Choose from nine upgrades to fit your site’s needs

- Use remote monitoring and diagnostics (RM&D) for remote asset health insights

- Remotely keep your assets in their best operating condition through automapping and remote combustion tuning

Surveillance systems and remote control

This solution includes the following software upgrades:

Controls for de-manning including the following features

- Hardware and connectivity to improve hardware fault tolerance

- Synthetic sensors to improve fault management

- Advanced features to enable remote service calibration

- Advanced control logics to increase unit reliability, availability, and maintainability (RAM) in unmanned operation

- Effective alarm and alerts rationalization according to ISA 18.2

Oil-quality monitoring system

- Online information on both synthetic and mineral oil status during operation, to improve diagnostic capabilities and help customer defer oil sampling campaigns and lab analysis from 1–2 times per month to once per year

Surveillance systems

- Replaces manned routine inspection activities supporting remote troubleshooting

Oil debris monitoring

- The system comprises a sensor, signal conditioning unit, and controller which processes the particle count, providing warning as debris particle count increases