Highlights

Highlights

Benefits

- Extends pump life five times longer

- Withstands aggressive oil and gas environments, including abrasive and corrosive fluids

- Coats entire stage and demonstrates excellent adhesion strength to substrate

Applications

- Corrosive well fluid conditions

- Abrasive conditions with high sand and solids content

Overview

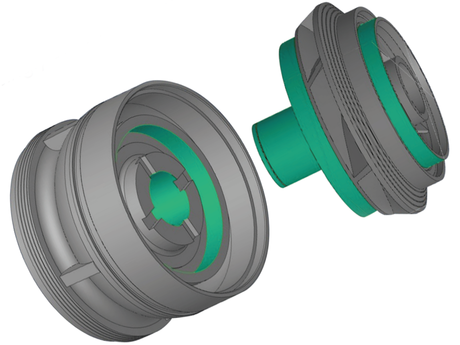

Get assured protection for your electrical submersible pumping (ESP) stages under corrosive, abrasive conditions with the ARMOR™ XS protective coating from Baker Hughes. The innovative, highly resilient coating protects each stage from sand or solids in your production fluids—enabling longer pump life and production rates in unconventional sandy wells.

The Armor XS coating has been chemically formulated to deliver a hard coating with uniform thickness and dense, consistent microstructure on components including impellers, diffusers, and modular thrust bearing components. As a result, the coating delivers significant benefits with respect to corrosion, abrasion, and run life of pumps over both the standard material stage and stages that use existing coatings for downhole oil and gas well environments.

Contact us today to learn how Armor XS protective coatings can prolong your ESP run time in challenging wells.