Highlights

Highlights

Benefits

- Ensure flexible, repeatable choke positioning to optimize commingled flow

- Allocate injection rates among various intervals

- Ensure effective sealing and eliminate erosion damage in high-rate flow with robust materials of construction

Applications

- Multizone production or injection wells

- High-value wells

- Intelligent wells

Overview

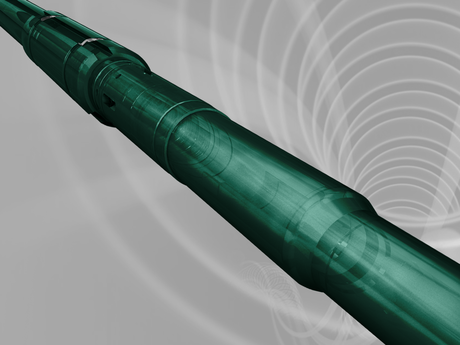

Get high-resolution, selective control of production or injection flow rates in specific intervals, without a costly intervention, with InFORCE™ sliding sleeves from Baker Hughes. These hydraulic sliding sleeve valves are ideally designed for commingled flow applications and give you an unparalleled ability to fine-tune flow from intervals to optimize your production.

Ensure well performance in various flow scenarios

Select from a range of InFORCE sliding sleeves depending on your wellbore conditions and production demands.

- For downhole flow control in less complex commingling wells, the HCM-Plus™ remote-controlled hydraulic valve provides unsurpassed reliability in a simple, robust design. The valve uses a patented diffuser ring system and equalizing slots to open repeatedly under high differential pressures. The HCM-Plus is designed for assured performance in high-solids environments, including a balanced piston actuator that provides more than 15,000 lbs of axial load—both upward and downward to the sliding insert—to overcome debris and scale buildup.

- The HCM™-A hydraulic sliding sleeve gives you definitive choke positioning control through a J-slot and bearing sleeve mechanism. Change choke position by applying hydraulic pressure from the surface. The sleeve is configured to provide six customized choke positions, plus open and closed. And in the event that hydraulic operations cannot be performed, a shifting profile enables mechanical operation.

- The HCM™-S downhole adjustable hydraulic choke valve is designed for assured commingled control as part of intelligent well completions. The HCM-S valve, which is available in both a 7,500-psi and 15,000-psi operating pressure rating, includes a Stepper Module that incrementally opens the valve to control communication between the tubing and annulus. This incremental control, which includes fully open and closed positions and up to 12 intermediate positions, helps selectively choke flow and control circulation, isolation, and selective-zone production.

InFORCE sliding sleeves are designed for durability, with a non-elastomeric sealing technology that ensures effective sealing between tubing and the annulus. And an optional shrouded sliding sleeve allows for seamless integration of InFORCE equipment with your sand control, multilaterals, and other completion technologies.

Contact us to learn how InFORCE sliding sleeves can optimize the production from your multizone wells.