Highlights

Highlights

Benefits

- Effectively clean out wellbores in one trip

- Deploy with other wellbore cleanup and fishing tools for additional efficiency gain

Applications

- Sub-hydrostatic wells with circulation challenges

- Wells with significant fine debris such as gravel and formation sand

- Wells with junk items including broken tools, hand tools, and slips

Overview

Downhole debris recovery systems from Baker Hughes give you proven solutions to remove sand and other debris from your well. Our debris recovery solutions, which have a track record of success in wells around the world, help ensure that your well interventions proceed seamlessly and efficiently.

Achieve effective wellbore cleanout with wide-ranging solutions

Effective removal and recovery of debris from your wells with production or flow challenges is a critical step to allowing production solutions to reach perforations.

Sub-hydrostatic wells with higher water cuts and lower well pressure lead to reduced annular velocities—thus increasing the risk of debris packing off and sticking to your coiled tubing. Larger volumes of debris can bridge and packoff easily if your annular velocities are too low.

Work with our application specialists to find the right debris removal solution for your specific production challenges. Our debris recovery techniques include:

- Concentric coiled tubing connected to our Sand-Vac™, Well-Vac™, and Tele-Vac™ downhole vacuum solutions to remove solids and liquids in a single downhole run

- Reverse circulation in which liquid is bullheaded down the annulus between the well tubing and workstring, allowing returns to come back up the tubing at a boosted velocity

- Nitrified/foam cleanouts that reduce the hydrostatic head of the well to improve flow velocity up the well

- Downhole debris recovery systems that operate on the Venturi principle to draw in debris at the bottomhole assembly and trap it for ultimate recovery to the surface

Remove debris with flexible VACS technology

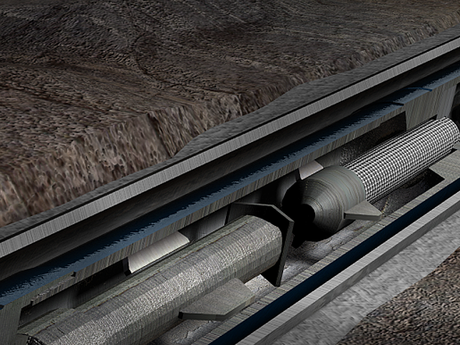

Downhole recovery systems such as the field-proven vectored annular cleaning system (VACS™) engine can be deployed with a diverter tube and junk basket tools to pull in and fine debris or junk from your well into the tool basket.

The one-trip cleaning and junk retrieving capability of VACS offers significant savings in time and cost. It is designed to operate and perform with other Baker Hughes wellbore cleanup and fishing tools, offering even greater flexibility. The VACS allows you to clean out long lengths by deploying workover motors and rotary shoes to break up and trap compacted debris. It can also be used with other fishing tools to clean and engage fish. And the time required to clean fine debris and retrieve big junk items is considerably shortened.

Contact us today to find out how our VACS technology and other debris recovery solutions can help you maximize your well’s production and profitability.