Highlights

Highlights

Benefits

- Increase mill life and penetration rates

- Minimize nonproductive time

- Reduce time in the hole with one-trip solutions

Applications

- Casing/tubing cutting and milling

- Thru-tubing fishing

- Subsea wellhead cutting and well abandonment

Cutting tools and services from Baker Hughes deliver a full range of cutting and milling services for your well workovers, interventions, or plug and abandonment (P&A) operations.

Maximize cutting performance in any application

Gain significant improvements in your mill life and penetration rates with our proven cutter technologies, which include:

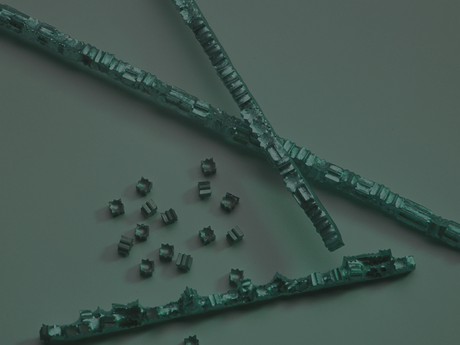

- METAL MUNCHER™ cutting structures offer efficient cutting performance in window mills, section mills, and pilot mills. The structures use a controlled cutting angle and chip-breaking features to cut the metal away, not merely grind it away. METAL MUNCHER cutters significantly reduce weight on the mill while delivering effective cutting on even high-content chrome steels.

- Opti-Cut™ inserts deliver proven performance in applications including thru-tubing fishing, packer milling, washover shoes, casing/tubular cutting and milling, or anywhere extremely sharp cutting edges are desirable. The geometry of each insert is optimized so that no matter how the cutter is placed on the body of the cutting or milling tool, there’s always a sharp cutting edge and point looking down. New cutting edges and points are exposed as the cutter is worn down.

- SUPERLOY™ cutters and Glyphaloy™ advanced milling technology carbide cutting structures work effectively on milling loose junk, such as bit cones, tong dies, packers, and for washing over stuck or cemented pipe. SUPERLOY cutters can dress off the outer diameter (OD) or inner diameter (ID) of casing for a clean top for your casing-patch operations.

- PDCs and surface-set diamonds for milling tools are a proven solution for cutting, milling, and underreaming operations involving hard material or hard formations.

Optimize your subsea P&A jobs

For your subsea well abandonment challenges, the Baker Hughes Terminator™ vessel-deployed subsea wellhead cutting system offers a simpler and safer solution compared to mechanical cutting, abrasive water jet cutting, or explosives. The Terminator system operates with minimal crew and reduced HSE exposure on the vessel and is effectively powered by ROV or other hydraulic power source, with no separate umbilical required. The Terminator can effectively cut your wellhead in a single trip, thus minimizing the time and costs or your abandonment operation.

And for effective cutting of multiple tubing strings in your subsea wells, count on the proven performance of the Hercules™ multi-string cutter. The Hercules cutter uses METAL MUNCHER inserts in an optimized placement design to ensure single-trip, high-wear durability. And with its self-centralizing, controlled knife force and adjustable rotational speed, you’re assured reliable, consistent performance in your multi-string cutting operations.

Ensure effective cutting of larger OD strings

Our proprietary cutting structures can be deployed to deliver effective cutting of your largest tubing strings. When dressed on high expansion milling tools, our cutting structures can pass through reduced ID strings. When the target location is reached, these tools can be flow actuated and expand up to 300% of the running outer diameter OD.

Once activated, our tools can mill / underream to the casing wall in the larger tubular / liner. You can also select from hydraulic-expandable cutting tools with similar designs to cut all grades of metals in tubulars up to 9-5/8-in. OD.

Contact us to learn how cutting tools by Baker Hughes can optimize your cutting and milling operations.