1-Oil and Gas Industry Must Transform to Lead in the Energy Transition.

In the call to action that echoed loud and clear from Florence - from the opening speech, to the international panels of energy experts, representing IOCs, governments and environment agencies on the stage: the oil and gas industry is facing a dual challenge. Listen to the opening keynote.

Emissions are actually increasing despite efforts to reduce them; and yet the demand for energy continues to rise, including those 850 million people who are currently without it. How do we meet the worlds demand for energy today, while transforming for tomorrow?

The IEA’s Dr Fatih Barol led the discussions by saying that minimizing emissions should be the first order of priority for all companies, as 15% of global energy related GHG emissions come from the process of getting oil and gas out of the ground and to consumers.

There was agreement that the oil and gas industry must continue to provide reliable, efficient, safe and productive energy to those who need it the most, whilst continuing to transform at its core and take on the challenge of climate change and carbon footprint reduction.

Technology and innovation is seen as critical to addressing this challenge, and many of the latest innovations were explored during the technology breakout sessions.

2-Gas will fuel the future

The conversation around the dual challenge focused on three solutions to potentially reduce emissions in the energy sector: improving efficiency with digital transformation thanks to sensing and monitoring, the fuel mix- from transition and new fuels, and investing in technology for energy storage, such as carbon capture and storage (CCS).

On the topic of gas demand, projected gas demand growth shows that there is going to be space for everybody, and today’s partnerships will support the future. According to the IEA, since 2010, coal to gas switching has saved around 500 million tons of CO2.

On stage and in the breakouts, participants heard that LNG and natural gas are a long-term and fundamental solution to develop and maintain a low carbon economy.

The discussion also considered the role of policy and how there is a need for industry to become engaged in supporting policies that will act as a catalyst for growth in efficiency and decarbonization. Emissions management is the key for success, according to Mark Brownstein, Senior Vice President of Energy, Environmental Defense Fund.

A number of conference speakers and participants, from LNG operators, to other industrial users such as transportation agreed that gas will be a vital fuel as the industry continues its energy transformation whilst supplying safe and reliable energy to the world.

3-Digital transformation is happening now

Over the past few years, Annual Meeting participants have addressed the need to collaborate to advance the industry and accelerate its uptake of disruptive technologies: 20% of polled attendees confirmed that Digital Transformation is critical to the industry right now.

This year, conversations focused on how to rapidly integrate data from enterprise systems, operational sources, sensor networks and external providers to power machine learning models that generate predictive insights at enterprise scale.

Many operators and digital partners have joined forces- such as Baker Hughes and C3- to bring together oil and gas expertise with AI software capabilities, in order to deliver digital transformation technologies that will drive new levels of productivity in the industry.

Several sessions at the AM2020 were dedicated to technology currently available to monitor health and predict failure of systems, subsystems, assets and components using such advanced algorithms, which in turn can help prioritize maintenance expenditures, and directly operationalize maintenance through seamless integration with existing work order management and business systems.

To find out more about how an AI application visualizes, analyzes, and optimizes upstream oil and gas operations- visit latest announcement on BHC3 Production Optimization.

4-Offshore developments face challenges, and new opportunities

For offshore operators, the last few years have been focused on decreasing development

time and being more proactive in order to keep up with market dynamics. Flexibility, contractual and legal, and having a more streamlined approval process have enabled some of the recovery.

Most new discoveries are in deep water, and the main challenge is to find ways to improve economic viability of such projects, as was discussed in the plenary panel discussion dedicated to offshore projects. With many national operators involved, services companies and all partners must engage with governments early to get the support needed to move forward to FIDs.

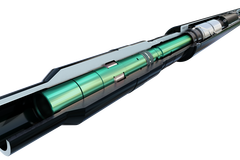

Another key takeaway is that standardized products make localized training easier and helps with development time and economics, all important elements for projects in regions. Our Subsea Connect strategy has enabled some of this approach.

It was important to note that Subsea and Offshore developments are also now targeting zero flaring-in the energy transition context.

5-The ways we design, manufacture and work are changing

At AM2020, drones, sensors, and automated machines were on display. Not your typical oil and gas equipment. The technology showcase included Avitas, a smart inspection and monitoring solutions company which focuses on three areas: automation solutions, environmental solutions and AI solutions.

With robotics and powerful analytics, a drone can flyover many well sites in a single day, ingest all the data and produce information to help make maintenance decisions, instead of this being done ‘manually’ by an operator driving from well pad to well pad each day.

Also, both in the exhibition and the tech breakouts, it was clear that additive is transforming the future of design and manufacturing. Read more here about Additive Manufacturing: The beautiful disruptor.

Participants heard how processes that once took months or years now take days or weeks and customization can be carried out at no extra cost. Additive is key to digital transformation and this is a huge opportunity for this industry to achieve new levels of efficiency. Additive manufacturing greatly reduces materials waste and cuts shipping distances, improving the overall efficiency of the production and supply-chain process. The parts themselves are lighter and many are already out-performing their subtractive-manufacturing ancestor.

Find out more key event takeaways from the conference speakers here.

Energy Forward Stories

Sign up to stay up to date on the latest innovations and people shaping the future of our industry.