Highlights

Highlights

Benefits

- Efficient and reliable units deliver high compression ratios, wide flow range, and optimal rotor balance for low vibration

- Number of stages, rotating speed, impeller diameter, and cooler size can all be tailored to suit any application

- Simple installation: units are delivered tested and fully assembled on a single base with no requirement for special foundation

Features

- Available in single or multi-shaft configuration to suit required duty

- Can be driven by an electric motor or a steam turbine; can have 1-4 pinions depending on casing size

- Automatic capacity control and safety system to reliably match any operating condition and reduce energy losses

Applications

- Petrochemical

- Air compression

- CCS/EOR/CCUS

Overview

Overview

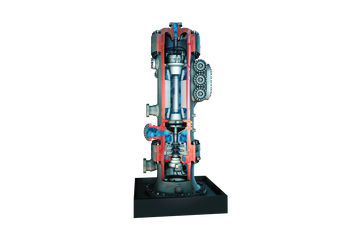

With a simple, compact structure, low vibration, and excellent reliability, our SRL high efficiency compressors are well-suited to a wide range of heavy-duty service with air, steam, and gasses for all petrochemical applications. As the OEM, we combine proven, standardized components with customization options to meet any operating requirements.

Specification

Discharge pressure

Up to 210 bar

Inlet flow range

1,600 to 360,000 m3/h

Max number of phases

Up to 8 phases

Speed

Up to 49,000 rpm

Configuration

Integrally geared

Integrated solutions for high-pressure applications

The SRL series can process CO2 streams from gaseous up to supercritical conditions as high as 540 bar.

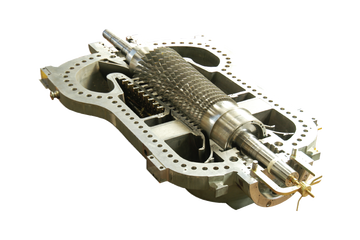

The optimized train configuration includes an integrally geared centrifugal compressor coupled with a multistage barrel pump for high pressure. The compressor's inter-stage coolers enable high CO2 pressure, ensuring high efficiency and 10% less power consumption than a traditional in-line compressor.

The high-pressure multistage barrel pump for CO2 draws on the proven design features of our installed fleet of 1,000 pumps. The pump train has been optimized to ensure high performance and operational flexibility, including selection of the intermediate pressure between the last compression stage and the pump suction. Moreover, with a smaller layout and casing and the highest enclosure standard, our integrated solution decreases total noise level, absorbed power, and cost—whether total lifecycle cost or cost per unit of CO2 injected underground.