Highlights

Highlights

Benefits

- Proven design experience to control pulsation and vibration ensuring high fatigue resistance and low downtime

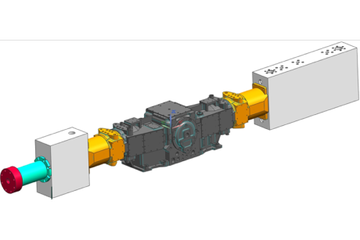

- Unique frame design eliminates auxiliary crosshead; a highly consolidated crank mechanism enables perfect parts alignment

- In-house fabrication, manufacturing of critical cylinder components, and assembly to ensure highest quality standards

Features

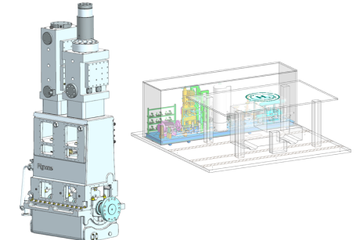

- Modular design enables most capacity in the smallest footprint with up to 12 cylinders on a single frame

- Twin-frame hypercompressor driven by a single motor can fulfill the highest capacity required, even higher than 400 kT

- New patented packing cup and valve can boost performance by containing pressures up to 3,500 bar

Applications

- LDPE

Video

Baker Hughes Reciprocating Compressors Solutions for LDPE Platform

Discover more about the Baker Hughes API Primary Reciprocating Compressor and Hypercompressor: our reciprocating technology is designed for easy maintenance to minimize life cycle cost.

Overview

Overview

Our LDPE hypercompressor modular design is the simplest way to get the most capacity in the smallest footprint. For the most extreme conditions in all LDPE applications, it ensures higher-efficiency results with low operating costs and easy maintenance over a very long and reliable life.

Frame size/model

PH

PK

Throws

4-24*

4-24*

Max. power**

36,000 kW

72,000 kW

Max rod load

1,450 kN

2,900 kN

Max. speed

310 rpm

310 rpm

* Number of cylinders; up to 12 cylinders in a single frame

** At max. speed and max. number of cylinders

Product Resources

1

Case Study

Simple, cost-effective process gas recovery

Simple, cost-effective process gas recovery