Overview

Our StimGun™ propellant-based products dynamically clean and stimulate the near-wellbore area. The StimGun family comprises three unique product offerings that allow maximum stimulation design flexibility for a wide range of well configurations: StimGun assembly, the StimTube™ tool, and the Well Stimulation Tool™ (WST™)/Horizontal Stimulation Tool™ (HST™).

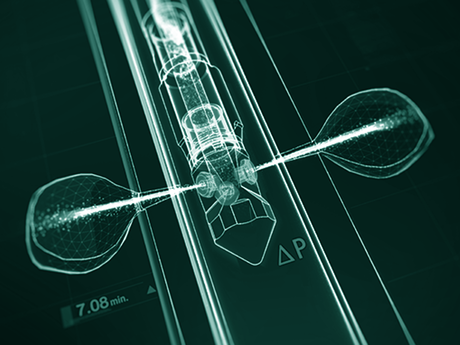

The StimGun assembly has two major components: the perforating gun and the special propellant sleeve surrounding the gun. This is the only product that can be placed across the perforating interval. When the propellant sleeve is ignited during the perforating event, a burst of high-pressure gases enters the formation and creates fractures. The result is improved penetration into the formation and greater connectivity to the wellbore.

The StimTube tool, HST system, and WST system efficiently stimulate wells that have existing perforations or openhole completions, offering economical alternatives to recompletion and remediation.

An integral portion of the StimGun family of products is the pre-job design analysis from our PulsFrac™ modeling software. PulsFrac software analysis results define job parameters, such as propellant quantity, fluid-level requirements, pressure magnitude, and duration. PulsFrac analysis also generates the expected perforation tunnel cleanup, breakdown, and fracture results.

A PulsFrac model should be completed before running StimGun products to identify whether the well is a candidate for propellant-based stimulation or cleanup.

The marks StimGun and StimTube are trademarks of Marathon Oil Company and are used with permission.