Highlights

Highlights

Benefits

- Perform multiple operations in one trip to reduce nonproductive time

- Improve reliability and eliminate set-down weight with hydraulic activation

- Ensure high flow rates with large circulation ports

Applications

- Openhole cleaning

- Deepwater wells

- Fluid loss maintenance

Overview

Ensure reliable mid-string circulation during wellbore cleanup, fluid displacement, and drilling with the Baker Hughes XP circulation valve. This hydraulically-activated tool boosts annular velocity to improve debris removal in wellbore applications from the conventional to the complex.

Ensure effective wellbore cleaning in multiple applications

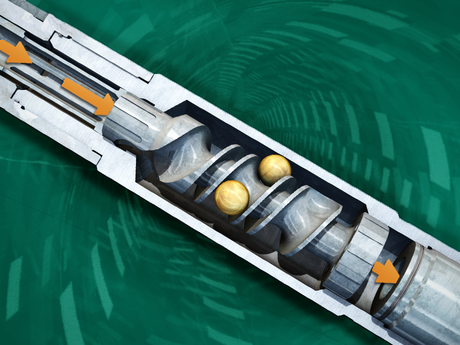

The valve is ball-drop activated, which improves reliability and eliminates the need for set-down weight. This feature also makes the valve suitable for situations where mechanical operation is not feasible.

The XP circulation valve can be used in deepwater casedhole displacement and to provide excellent debris removal in wellbore cleanup and blowout preventer cleaning. In these applications, the circulation valve can be run as part of the complete X-Treme Clean™ XP wellbore cleanup system.

In drilling applications, the valve is typically run in the bottomhole assembly above under-reamers and measurement-while-drilling (MWD) tools.

The valve provides three flow modes: to the bit, to the ports only, and flow split through bit and ports. In run-in position, all flow is directed through the bit. Depending on your application, the tool’s secondary flow path can be reconfigured by first dropping the right-sized ball. If you need to boost annular velocity for debris removal, a different-sized ball can be dropped to activate the tool while maintaining a split flow path.

Operate with ease, through multiple cycles

The XP circulation valve is operated through a simple process. To open the valve, a ball is dropped from surface to shift the internal sleeve, which open the ports for circulation. Depending on the size of the ball dropped, the tool’s flow path to the bit will either be closed off or left open.

Dropping a second ball returns the internal sleeve to its run-in position, sealing off the ports and allowing circulation through the tools. All balls are stored within the circulation valve in the integrated ball catcher sub, eliminating the need to run additional catcher tools in the string.

This tool can be operated in multiple cycles, which are limited only by the capacity of the integrated ball catcher sub. The tool also has a full internal flow path that allows smaller balls to be circulated through for activating or deactivating any tools below. The circulation valve’s high torque and tensile ratings make it ideal for deepwater and ultradeepwater operations.

Contact us today to find out how the Baker Hughes XP circulation valve can help you successfully perform high-rate circulation operations in your completion or drilling applications.