Highlights

Highlights

Benefits

- Mean time between maintenance (MTBM) of 32,000 factored fired hours (FFH) or 1,300 factored fired starts (FFS)

- Capable of single-digit NOx emissions

- Can burn a wide range of gas and liquid fuels, syngas option, low emissions, grid support, peaking, cyclic and base load modes

Features

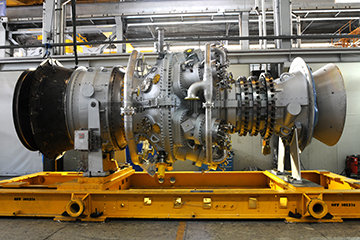

- Single-shaft engine with hot-end drive, 17 axial compressor stages, and 13.1:1 pressure ratio

- 14 combustion chambers with reverse-flow STD/DLN1+ combustion system (single-digit NOx emissions)

- Three turbine stages with air-cooled first and second stage nozzles and buckets

Applications

- Simple cycle and cogeneration

- Combined cycle with steam turbine

- LNG

Overview

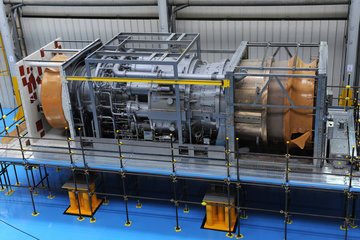

This turbine's success in the 100-150 MW class stems from an excellent fit in a wide variety of applications with many customers—including oil and gas, petrochemical, industrial, and electric utility.

DLN1+ specification. At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Package dimensions include driven equipment.

Proven

With more than 700 units installed worldwide, the Frame 9/1E provides proven energy efficiency, availability, reliability, and maintainability.

Fuel flexibility

It can operate with syngas/process gas, distillate oil, crude/residual, or natural gas in a variety of applications—and it can burn fuels with high hydrogen content (refinery and petrochemical).