Highlights

Benefits

- Ensure effective frac treatment while avoiding production blockages

- Keep debris blockages out of the production string

- Ensure effective disintegration using common frac and formation fluids

Applications

- Formations requiring multistage hydraulic fracturing

- Wells with pressure differentials between stages, wells with low production velocity

- Plug and perf applications in which rigs for plug millout operations are scarce or expensive

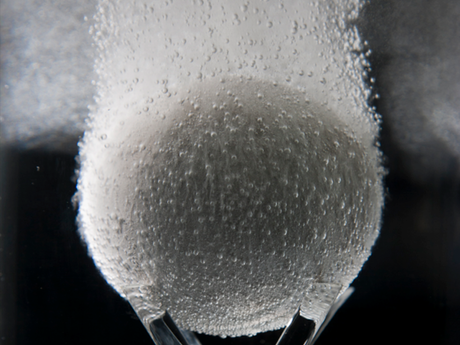

Eliminate your risk of lost production due to frac balls in the well with IN-Tallic™ disintegrating frac balls from Baker Hughes. Composed of a controlled electrolytic metallic (CEM) nanostructured material, our disintegrating frac balls maintain their shape and strength during hydraulic fracturing and then disintegrate to ensure unhindered production.

Get assured stage isolation and unimpeded production

The IN-Tallic disintegrating frac balls have a nanomatrix grain structure that gives them unique mechanical and chemical properties that conventional materials don’t have. They are lighter than aluminum and stronger than some mild steels. The balls can be easily pumped into the horizontal section of your well and then provide effective stage isolation with a rating that exceeds some ball-activated fracturing technologies.

Use our IN-Tallic disintegrating frac balls with current frac sleeves in the FracPoint™ multistage fracturing system and with the ball- activated QUIK Drill™ composite frac plugs. Once fracturing is complete, the frac balls disintegrate over time when exposed to brine fluids, which includes most fracturing and wellbore fluids. The disintegration rate depends on temperature and the concentration of the brine.

Acids can be introduced to disintegrate the balls at a much higher rate. This gives you the flexibility to pump acid on the ball after the fracture is complete to speed up the disintegration process.

The balls are fully disintegrated before or shortly after the well is put on production.

Avoid production problems common to standard frac balls

Our IN-Tallic disintegrating frac balls help eliminate the risk of lost production in your well due to frac balls. Because they disintegrate, the IN-Tallic frac balls help you avoid the obstruction risks common to standard frac balls. These include pressure differentials that cause standard frac balls to remain sealed on the ball seat and block production from all stages below.

Another risk associated with standard frac balls when using a ball-activated frac sleeve system is their tendency to pile up in your well’s low spots if the production velocity is not high enough to bring them back to surface. Any sand or other debris produced by your well can pile up with the balls to create a debris barrier.

Fixing these problems typically requires the additional time and expense of bringing in a coiled tubing unit or workover rig to mill out the balls and ball seats—or simply accepting the loss of production from stages below the obstruction. Our IN-Tallic frac balls give you a simpler option by disintegrating before they cause an obstruction—thus preventing these scenarios from ever occurring.

Contact us today to find out how our IN-Tallic disintegrating frac balls can divert treatment while avoiding wellbore blockage in your wells.