Highlights

Highlights

Benefits

- Excellent availability and reliability as a prime mover; designed for long life

- Enhanced fuel flexibility with no impact on combustor’s operability or integrity

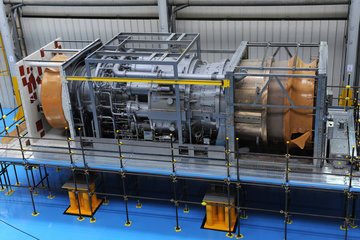

- Compact package design for easier maintenance; single-lift basement for engine and auxiliaries

Features

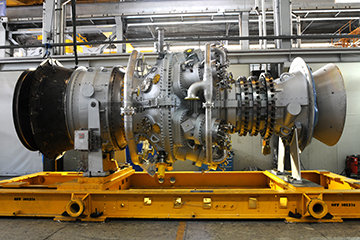

- 17-stage axial compressor adopted on former N, P, and PA models

- Multi-can DLN1 combustion system with dual-fuel capability for STD/LHE

- Single-shaft turbine hot-end drive architecture; two-stage turbine with uncooled buckets

Applications

- Refinery, petrochemical, and fertilizer

- Industrial, and combined heat and power

Overview

Over 300 units running with more than 38,200,000 fired hours experience. First commercial unit successfully exceeded 300,000 operating hours

At ISO conditions with natural gas fuel, ambient temperature 15°C, no inlet exhaust losses, sea level, 60% relative humidity. Assuming average efficiency of gearbox and generator. Package dimensions include driven equipment.

Fuel flexibility

A single-chamber, full-scale test campaign was conducted on DLN1 hardware to assess the combustor’s capability to operate with increasing C2+ levels in the fuel gas. Standard hardware currently installed on Frame 5/1PA DLN1 units are suitable to burn fuel gases with up to 40% C2+ (C2 to C4 alkanes) with no issues for the combustor’s operability or integrity.

Fuel composition

The Frame 5/1PA DLN1 can burn heavy hydrocarbons (25% max ethane content or 20% max propane), inerts (25% max CO2 or 25% max N2), hydrogen up to 20%, liquid fuel (distillate #2 at 42 ppm wet).

Performance enhancement

Maintenance plan enhancement (35,000/70,000 hours) can be provided as an option on the standard/LHE configuration.