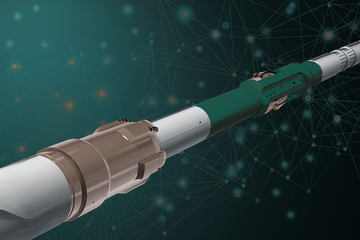

Directional liner drilling can take the risk and worry out of drilling through even the most challenging trouble zones. With Directional Liner Drilling Services from Baker Hughes, you get an integrated drilling solution that lowers drilling risks and shortens the time and risk of completing a well.

Whether you are trying to drill and land liner through low-pressure zones, unstable shales, or zones with widely varied flow and pressure regimes, our integrated solutions deliver tangible benefits.

Reduce your openhole exposure. Mitigate your risks of hole collapse and formation damage by drilling through and securing trouble zones in a single run.

Improve wellbore placement. Increase drilling efficiency and land the well to its target with the industry’s most advanced rotary steerable technology.

Minimize your downtime. Decrease non-productive time (NPT) by eliminating the need for extra reaming or circulating time, while avoiding a cleanout run to get the hole in gauge.

Deliver a stable wellbore. Ensure greater well stability through the plastering effect, which also reduces fluid losses and cuttings volumes.

Improve safety metrics. Improve your HSE metrics on the rig floor by reducing crew sizes for pipe handling and shrinking the rigsite footprint.

Make better real-time decisions. Capture and analyze downhole data including pressure, resistivity, gamma, neutron, and density from a full suite of modular formation evaluation tools.

Drive down your drilling costs. Employ our integrated, modular liner drilling solutions—without the need for specialized rig modifications—to increase rate of penetration (ROP), lower fluid costs, eliminate stuck pipe events, and reduce the volume of chemical additives required for well control.

Let’s work together to develop the optimal directional liner drilling program for your most challenging wells.