Overview

With decades of proven experience in the field, Baker Hughes provides a full range of solutions covering design and supply of equipment, plants, modules, and special processes for oil and gas treatment, sulfur recovery, and acid gas removal.

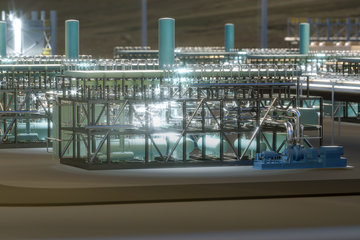

Our modular LNG solutions minimize project risks and schedules while reducing engineering and construction costs. Our installed fleet has power generation and compression modules, including many LNG export facilities.

Our own gas-treatment innovations include Claus units, tail gas treatment with High Claus Ratio (HCR) technology, and sulfur degassing. We provide customized engineering solutions for project-specific challenges, and our references include design and supply of the largest natural gas treatment plants for international transmission.

Customers rely on our comprehensive range of services from technology selection, design and detailed engineering to turbo-compression supply, project management, procurement, construction, installation and startup. We work on single process units (onshore and offshore) for plant revamps or expansions, and complex greenfield facilities complete with off-sites and utilities.

Our combination of innovative technologies, flexible service models, performance-based service agreements, and extensive data analysis from our installed fleets across LNG facilities and shipping show we have a proven record of improving LNG plant and trade performance.

We also offer training for customer operating personnel, as well as operational and maintenance support.

Why Baker Hughes?

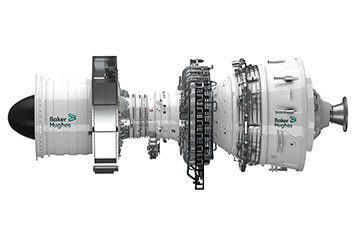

- Proven and best-in-class turbines and compressor technologies

- High reliability and availability and modular construction capabilities

- Proven expertise in natural gas processing and acid gas treatment

- Integrated approach, from technology development to installation

- Tailored, reliable, and cost-effective solutions—both stick-built and modularized

- Advanced digital services for process optimization