The cement sheath that seals your well from formation fluids is, ultimately, an investment in safety and environmental stewardship. In addition to supporting the casing, the sheath offers a sealed barrier that protects the casing from corrosion and underground source drinking water from contamination. Optimized cement systems and automated mixing equipment enable precise, safer slurries that match well conditions while minimizing rig time.

Advanced design technology

Baker Hughes cementing experts are committed to superior engineering. Leveraging advanced design technology including the CemVision™ advanced fluid displacement simulator software application, we apply high-quality products and additives using high-performance equipment for dependable, long-term cementing in every well, every time. By using the output data identified by the CemVision software — in either 2D or 3D visualization — solutions are tailored to reduce risks of intermixing while incorporating contingencies to meet cement placement objectives.

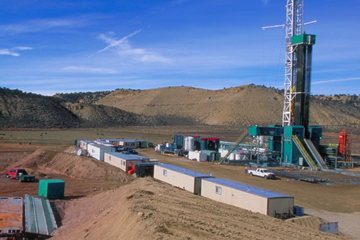

Scientists at our Technology and Operations Support Center are continuously developing new and more effective solutions to meet your well cementing challenges. Whether you’re working on land, deepwater, arctic, high-pressure/high-temperature (HP/HT), or conventional reservoirs, we consistently have a better approach.

Even as our technology extends the limits of cementing performance, one basic premise defines our success: A good cement job starts with a proper understanding of well design objectives and application of cementing best practices, including mud conditioning, job rates, densities, centralization, and other factors that maximize mud displacement efficiencies. These are critical elements for long-term zonal isolation.

Contact your local Baker Hughes representative today to invest in a safer and more effective cementing solution.